Method for determining maximum stress of annular thin film with rigid plate in center under uniformly distributed load

A technique of uniform load and maximum stress, used in special data processing applications, instruments, calculations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

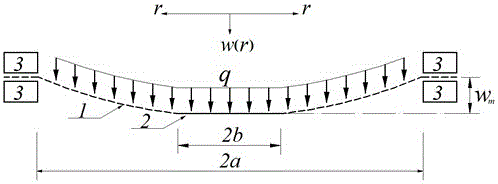

[0032] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

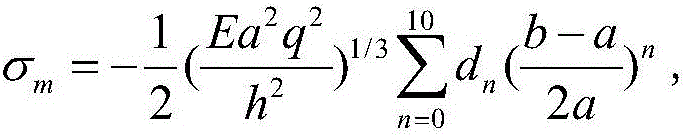

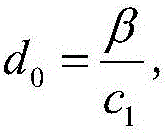

[0033] Such as figure 1 As shown, using a clamping device with an inner radius of a = 20mm, the rubber of a rigid plate with a thickness of h = 0.06mm, Young's modulus of elasticity E = 7.84MPa, Poisson's ratio ν = 0.47, and a center belt radius b = 5mm The film is fixed and clamped to form an axisymmetric ring-shaped film with a rigid plate in the center fixed and clamped around the outer radius a=20mm and inner radius b=5mm, and a uniformly distributed load q is applied to it in the transverse direction, and q=0.01 is measured MPa. Adopt the method that the present invention provides, by equation

[0034] ν = 2 - b a [ Σ i = 2 10 i ( ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com