A compensation system and compensation method of the inverter dead area used in vector control

A technology of dead zone compensation and vector control, applied in vector control system, control system, control electromechanical brake, etc., can solve problems such as difficult to improve accuracy, heavy workload, current clamping, etc., to reduce workload and improve performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

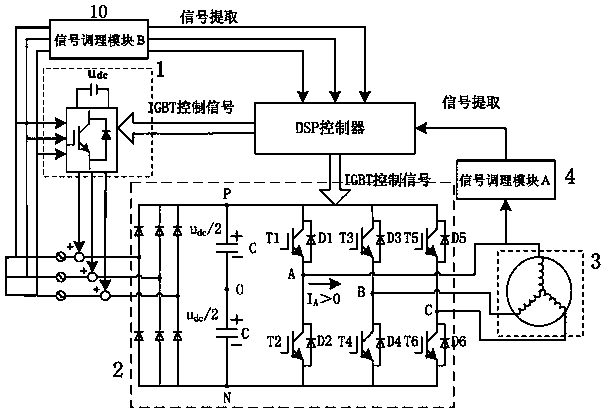

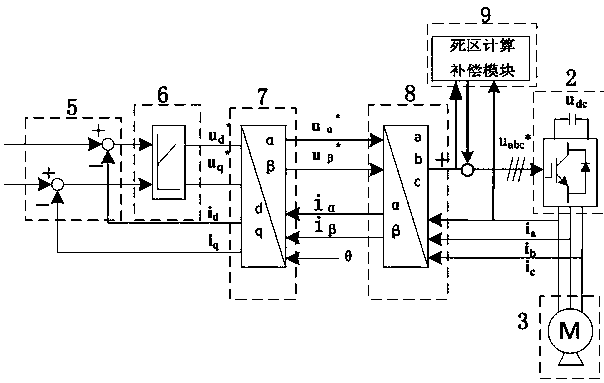

[0033] An inverter dead zone compensation system applied to vector control, comprising an induction motor 3, a dead zone calculation compensation module 9, a vector control module and an inverter 2, the induction motor 3 is connected to the inverter 2, and the vector control module The signal output terminal of the signal is connected to the inverter 2, the dead zone calculation compensation module 9 is connected to the output voltage of the vector control module, the output voltage after compensation is connected to the inverter 2, and the voltage is compensated to the inverter 2;

[0034] The vector control module includes an excitation current and torque current comparison module 5, a PI controller 6, a 2r / 2s conversion module 7 and a 2s / 3s conversion module 8, and the signal output terminal of the induction motor 3 passes through the 2s / 3s conversion module in turn 8 and 2r / 2s conversion module 7 are connected to the signal input end of the excitation current and torque cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com