Engine i No. fulcrum detection fixture and its composed detection system

A technology for detecting fixtures and engines, which is applied in the direction of measuring the rate of increase and decrease of fluids, and using liquid/vacuum degree to measure liquid tightness, etc., which can solve the problem of not detecting the RD-93 engine No. I fulcrum detector and the detection process of detection equipment Complicated, not reusable, etc., to achieve accurate air tightness testing, save testing costs, and accurate testing results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

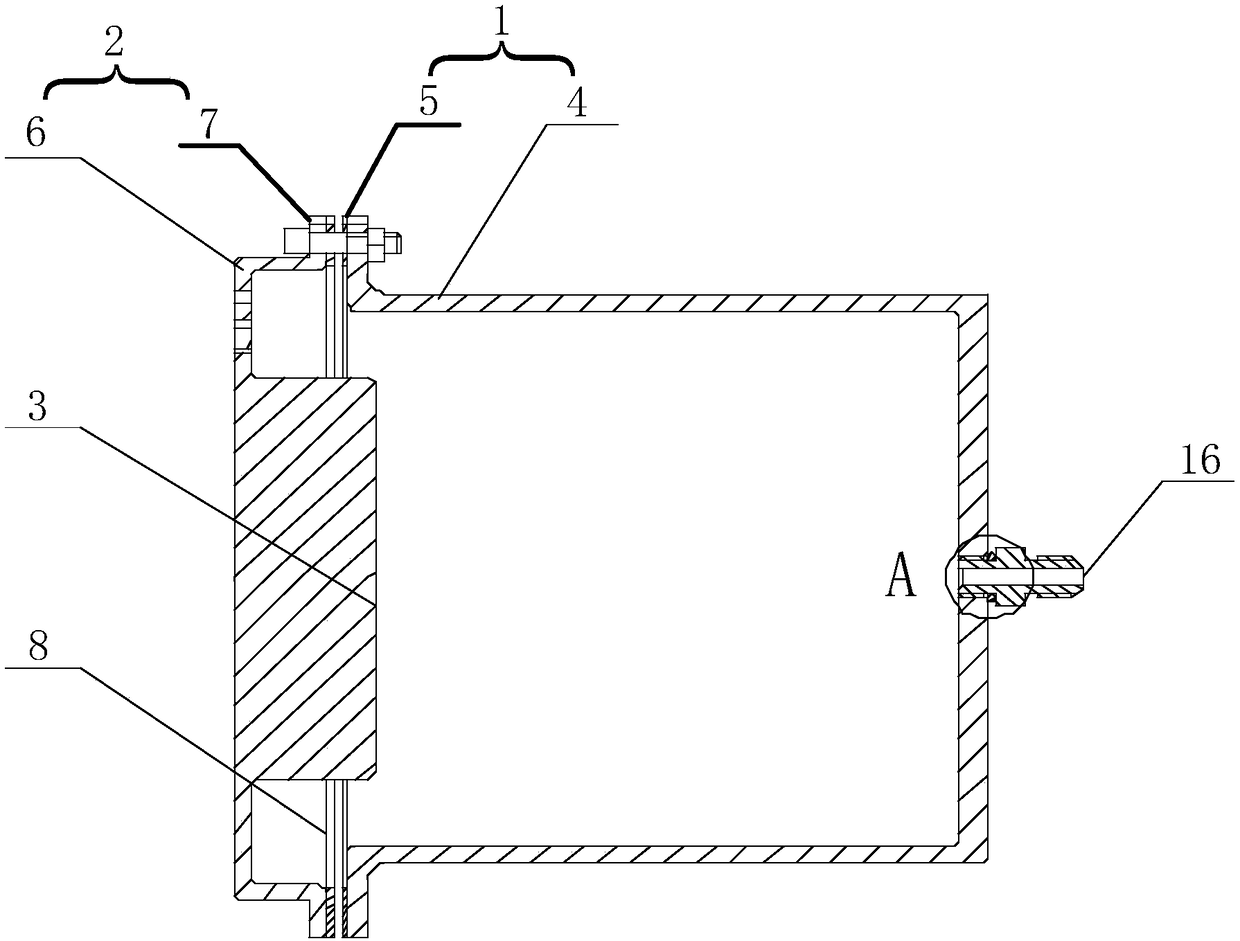

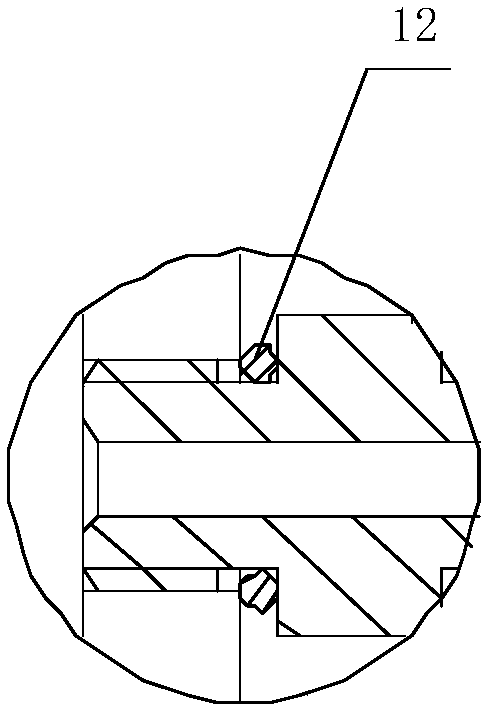

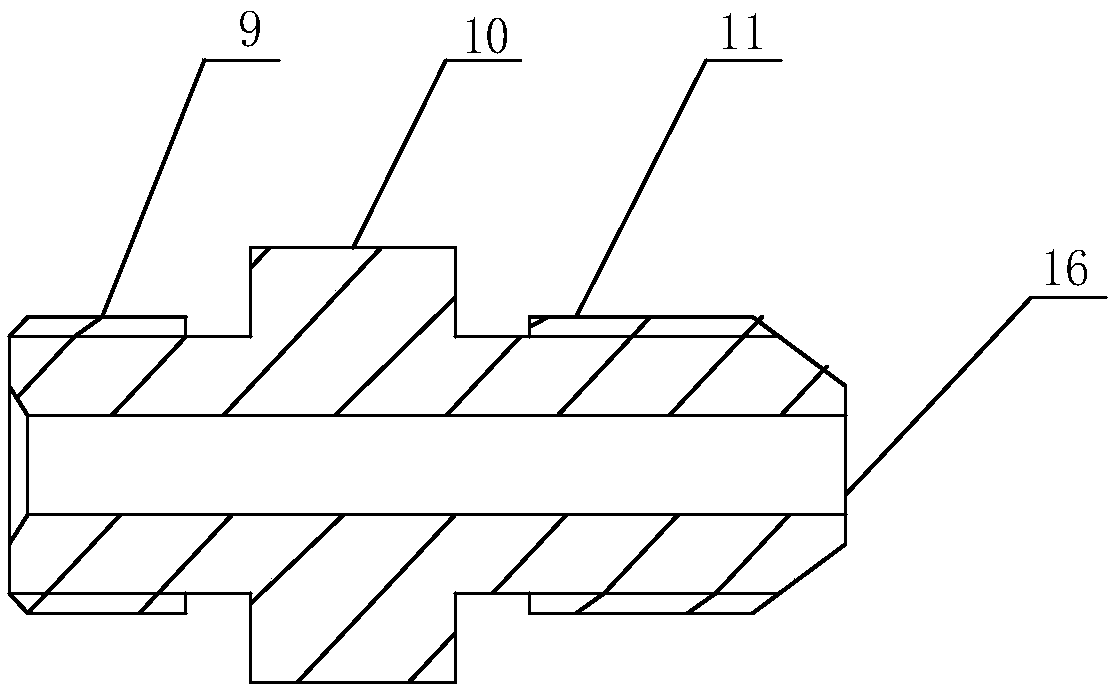

[0025] like Figure 1 to Figure 3 As shown, the No. 1 fulcrum detection fixture of the engine includes a gas cover 1 and a base 2 that all have a concave surface; the gas cover 1 and the base 2 are detachably connected; the concave surface of the gas cover 1 and the concave surface of the base 2 face each other; A simulation platform 3 is provided; the gas mask 1 is connected with a mouthpiece 16; the gas mask 1 includes a first U-shaped frame 4; the opening of the first U-shaped frame 4 is connected with a first connecting platform 5; the base 2 includes a second U-shaped Type frame 6; the opening of the second U-shaped frame 6 is connected with a second connection platform 7; the first connection platform 5 and the second connection platform 7 are detachably connected; the simulation platform 3 is connected with a plurality of gaskets 8; the gasket 8 The edge is located between the first connecting platform 5 and the second connecting platform 7; the first connecting platfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com