Multi-station camshaft press

A technology of camshafts and press-fitting machines, which is applied to assembly machines, metal processing, and tool manufacturing, and can solve the problems of wasted manpower and time, and large bump damage of camshafts, so as to achieve a simple and convenient overall layout and reduce bumps and damages , Improve the effect of assembly quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

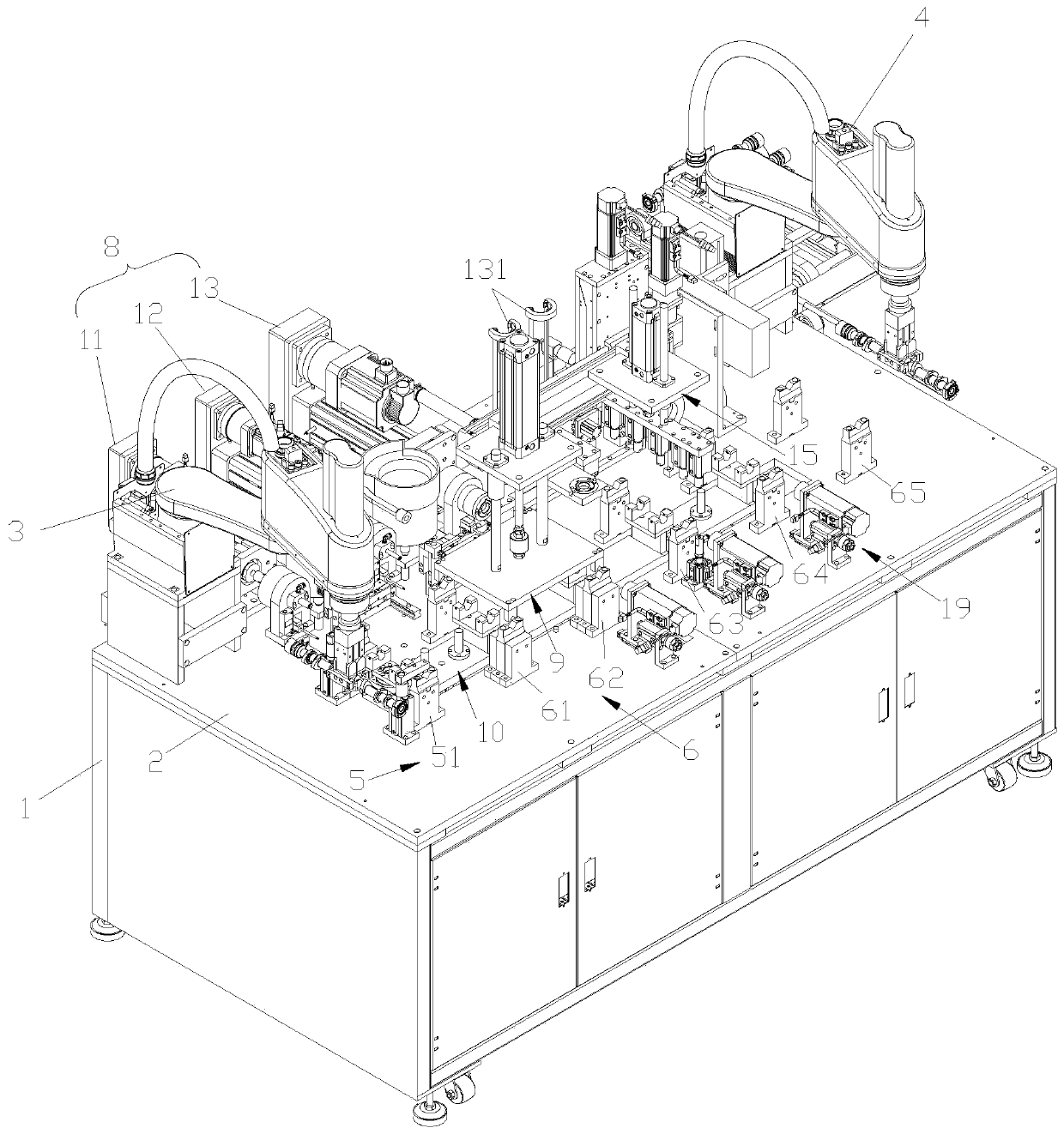

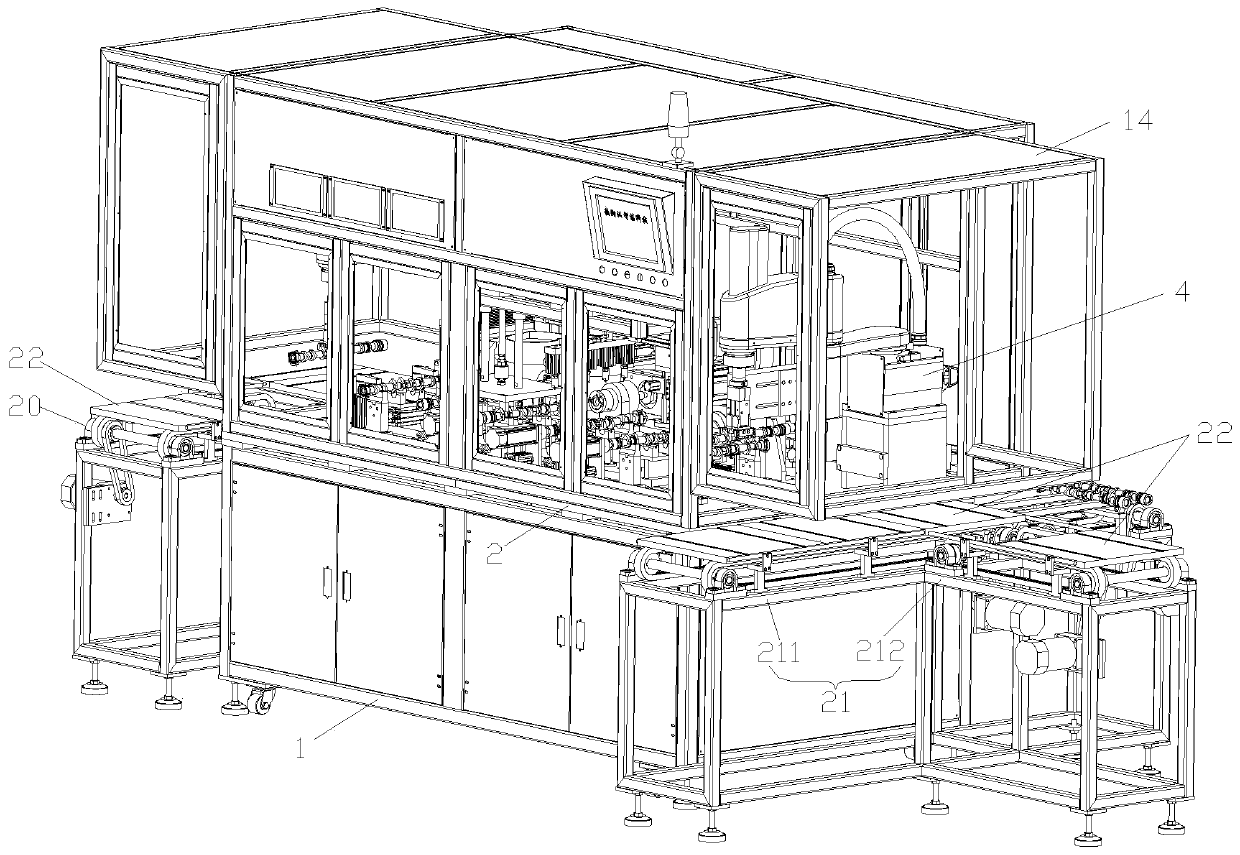

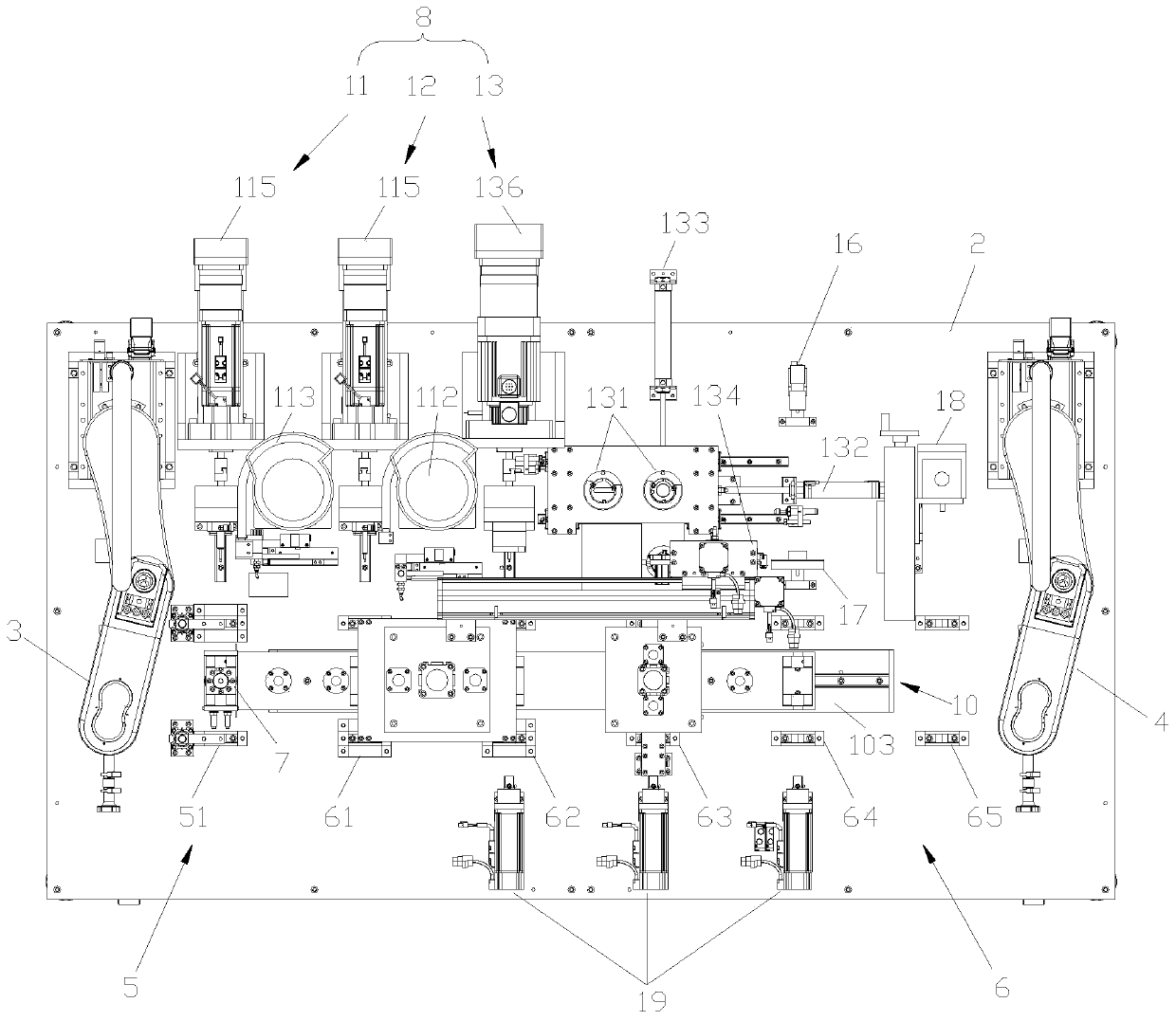

[0034] Embodiment 1 of the present invention: a multi-station camshaft press-fitting machine, constituted as Figure 1 to Figure 9 shown, see Figure 1 to Figure 3 , comprising a frame 1, the frame 1 is provided with a work platform 2, the two ends of the work platform 2 are respectively provided with a loading manipulator 3 and a material unloading manipulator 4, and the middle of the work platform 2 is sequentially provided with a sequencer Bit group 5 and reverse installation station group 6, a steering mechanism 7 is arranged between the forward installation station group 5 and the reverse installation station group 6, the forward installation station group 5 and the reverse installation station group 6 rows An assembly device 8 is provided on the same side of the fabric direction, a workpiece clamping device 9 is also provided on the forward assembly station group 5 and reverse assembly station group 6, and a workpiece overall displacement device 10 is also provided on th...

Embodiment 2

[0049] Embodiment 2: A kind of multi-station camshaft press-fitting machine, constitutes as Figure 1 to Figure 9 shown, see Figure 1 to Figure 3 , comprising a frame 1, the frame 1 is provided with a work platform 2, the two ends of the work platform 2 are respectively provided with a loading manipulator 3 and a material unloading manipulator 4, and the middle of the work platform 2 is sequentially provided with a sequencer Bit group 5 and reverse installation station group 6, a steering mechanism 7 is arranged between the forward installation station group 5 and the reverse installation station group 6, the forward installation station group 5 and the reverse installation station group 6 rows An assembly device 8 is provided on the same side of the fabric direction, a workpiece clamping device 9 is also provided on the forward assembly station group 5 and reverse assembly station group 6, and a workpiece overall displacement device 10 is also provided on the working platfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com