Automatic spotting device for torque converter pump wheel

A torque converter and pump wheel technology, applied in the field of automatic copper paste spotting device for torque converter pump wheels, can solve the problems of low production efficiency, cumbersome process, occupation, etc., to improve production efficiency, reduce labor intensity, and improve controllability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

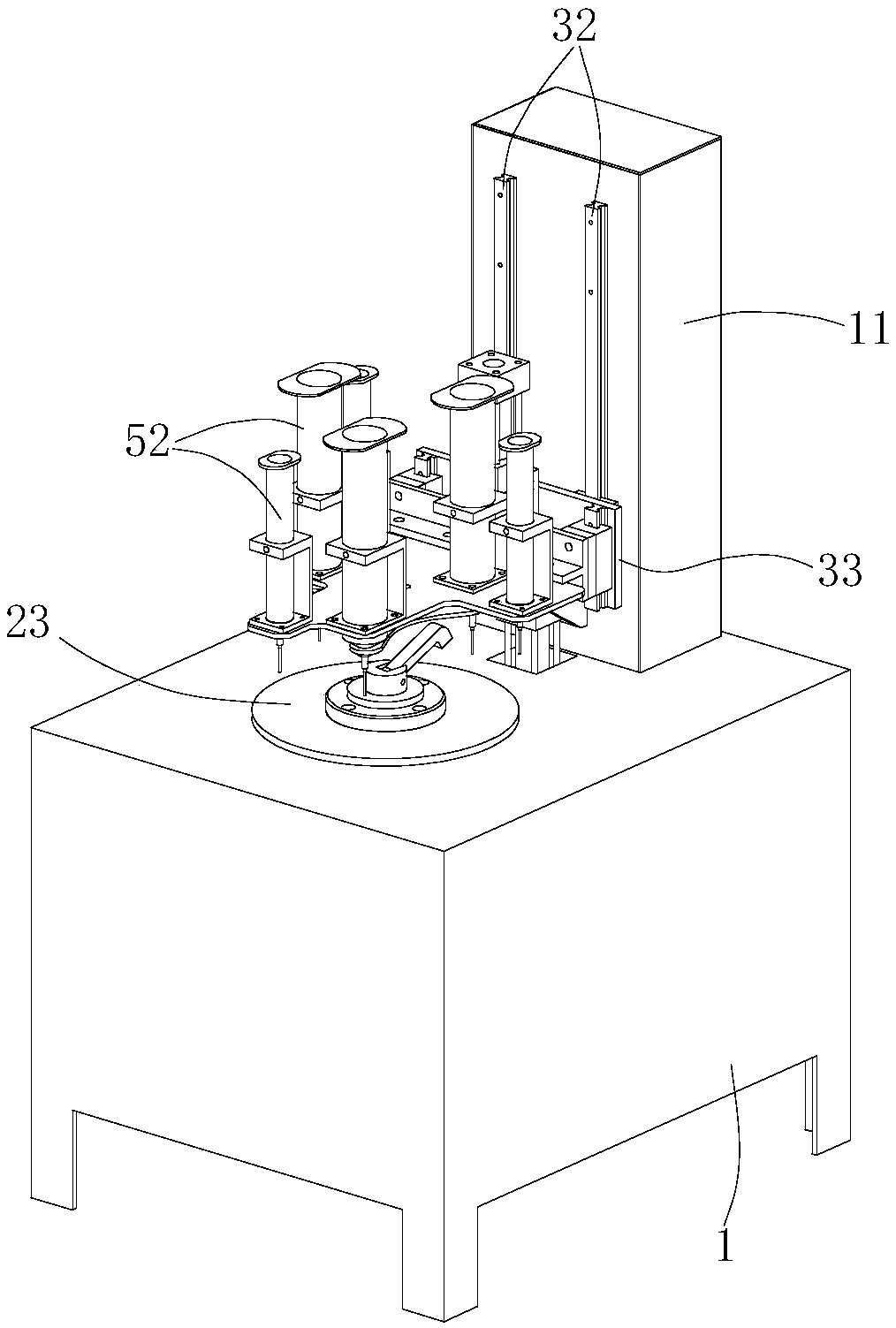

[0023] Such as Figures 1 to 3 shown

[0024] The device includes a frame 1, a pump wheel rotating assembly, a material point assembly, a first lifting assembly and a second lifting assembly.

[0025] The lower part of the frame 1 is in the shape of a square shell, and the upper end surface of the frame 1 is also provided with a fixing part 11 .

[0026] The pump wheel rotating assembly includes a deceleration stepping motor 21, a bearing 22 and a turntable 23. The pump wheel rotating assembly is arranged in the frame 1, and the frame 1 and the output shaft of the decelerating stepping motor 21 are matched by the bearing 22. The bottom of the turntable 23 Installed on the output shaft of the deceleration stepper motor 21, the turntable 23 of the pump wheel rotating assembly protrudes from the upper end surface of the frame 1, and the upper end surface of the turntable 23 is provided with a positioning boss 23a cooperating with the driving hole of the torque converter pump whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com