Display screen, terminal and display screen making method

A manufacturing method and a technology of a display screen, which are applied in the field of display screens, can solve problems such as affecting the visual effect of the display panel, failing to achieve a seamless integration, and differences in reflection intensity between the visible area and the ink area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

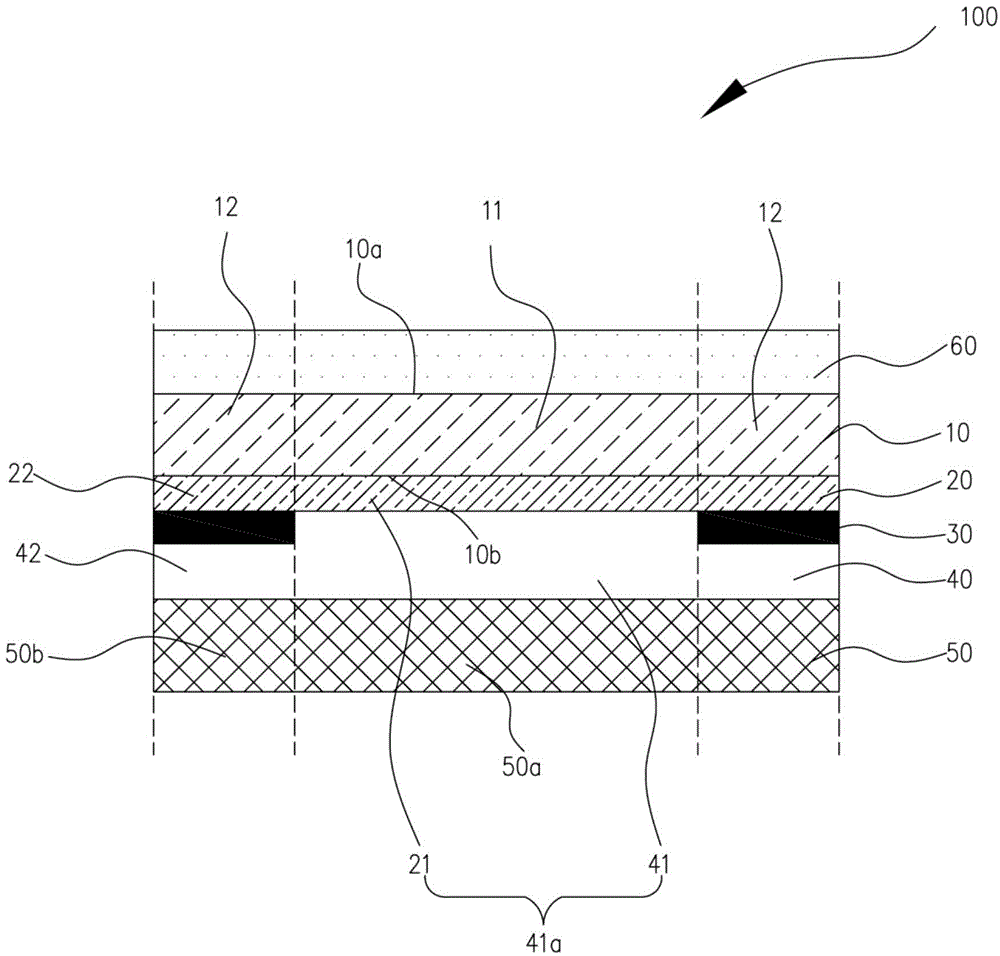

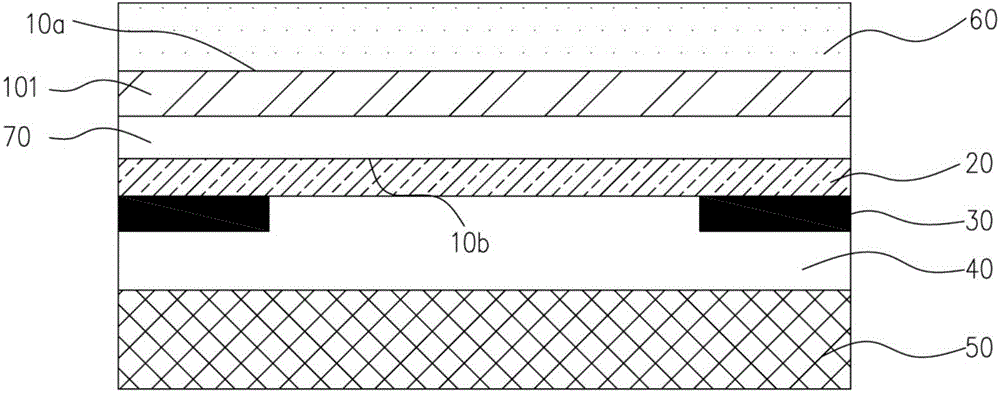

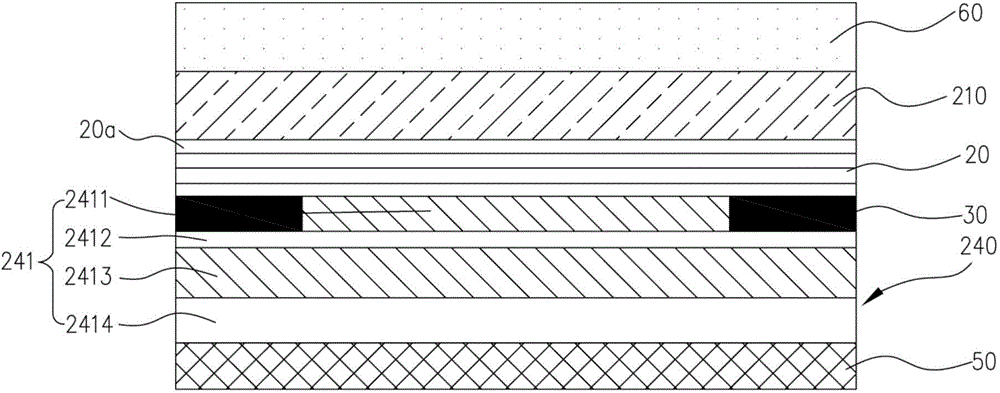

[0031] see figure 1 , a display screen 100 provided by the present invention, the display screen 100 includes a transparent protective plate 10, an optical film 20, an ink layer 30, a functional layer 40 and a display layer 50 stacked in sequence, and the transparent protective plate 10 has a visible window 11 and a non-visible window 12, the non-visible window 12 surrounds the visible window 11, the optical film 20 is laminated on the transparent protective plate 10, and has a first light-transmitting layer 21 corresponding to the visible window 11, and There is a second transparent layer 22 corresponding to the non-visible window 12 . The ink layer 30 is stacked on the side of the optical film 20 facing away from the transparent protective plate 10 and covers the non-visibl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com