A steel pipe automatic correction robot

An automatic calibration and robot technology, which is applied in the field of steel pipe automatic calibration robots and automation equipment, can solve the problems of lack of relatively mature steel tube calibration technology, and achieve the effects of simple structure, convenient operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with specific embodiments. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

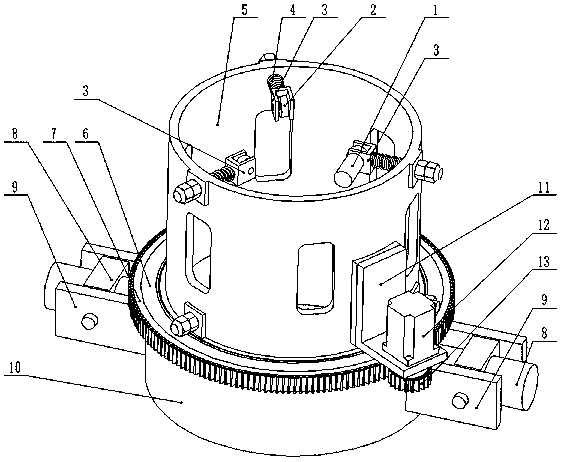

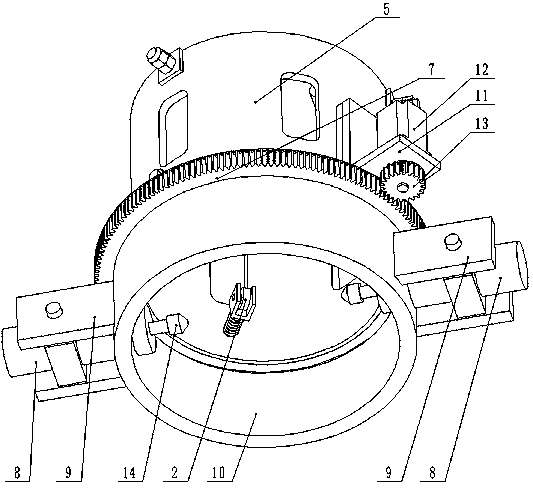

[0012] Such as figure 1 , figure 2 As shown, a steel pipe automatic correction robot includes an annular main frame 5 and a rotating frame 10, a rotating bearing 6, a large gear 7 and a pinion 13, a rotating motor 12 and a rotating motor mounting frame 11, six roller mounting frames 3 and six A roller 2, two roller motors 1, two hydraulic cylinder mounting frames 9, two hydraulic cylinders 8, and two pressure head top blocks 14. The annular main frame 5 is provided with six installation shafts, wherein three installation shafts are evenly distributed on the annular main frame 5 tops, and the other three installation shafts are evenly distributed on the annular main frame 5 bottoms, and are connected with the top t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com