Patents

Literature

39results about How to "Automatic correction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

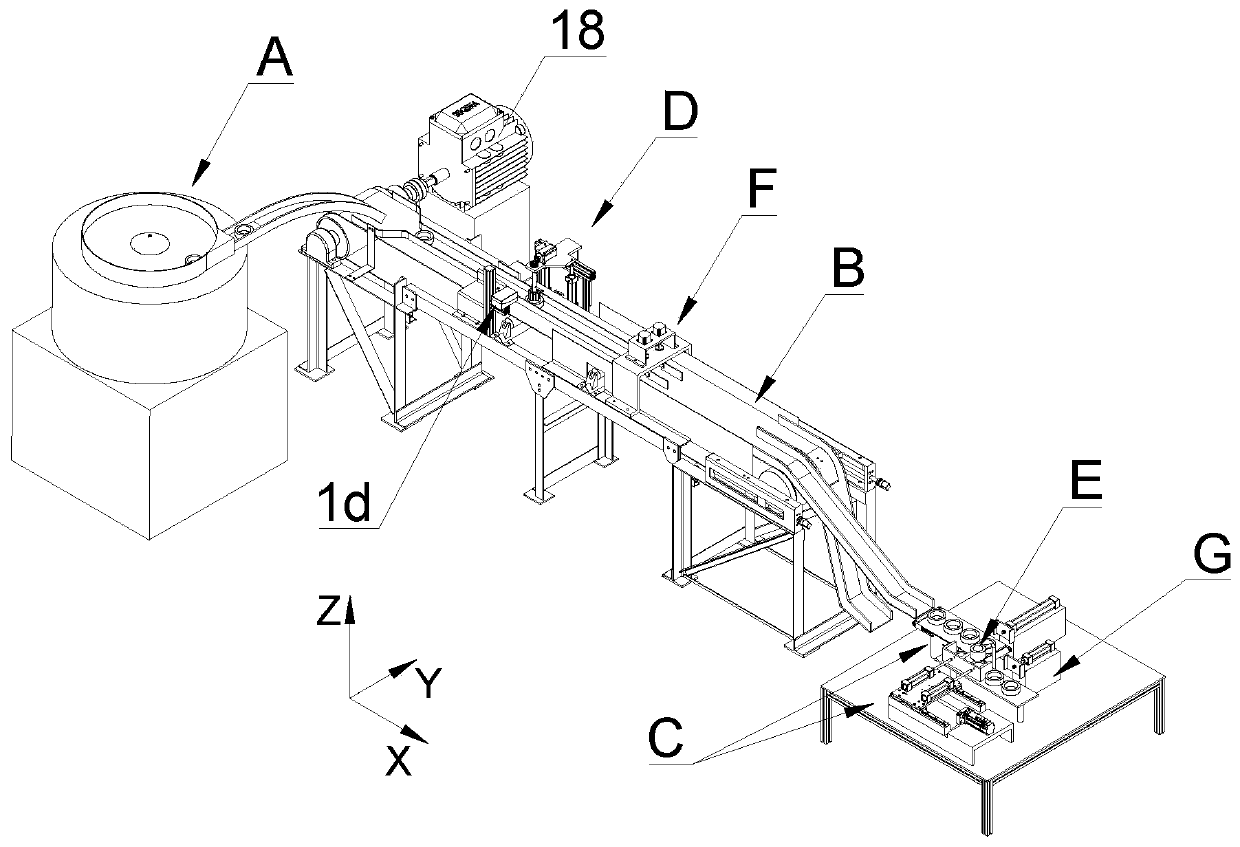

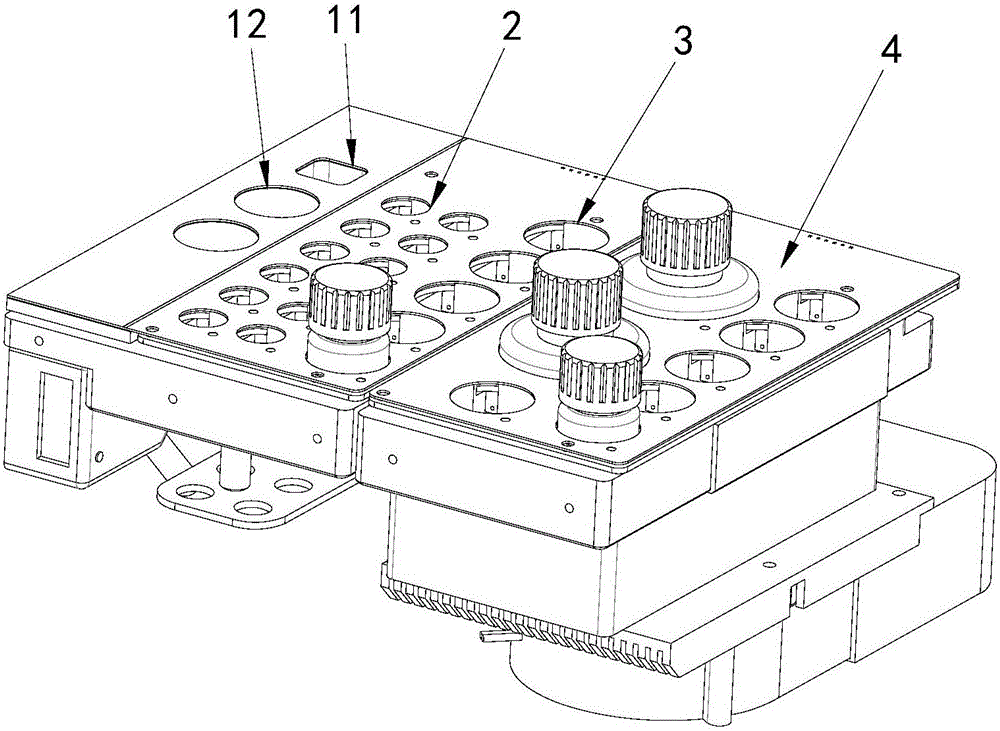

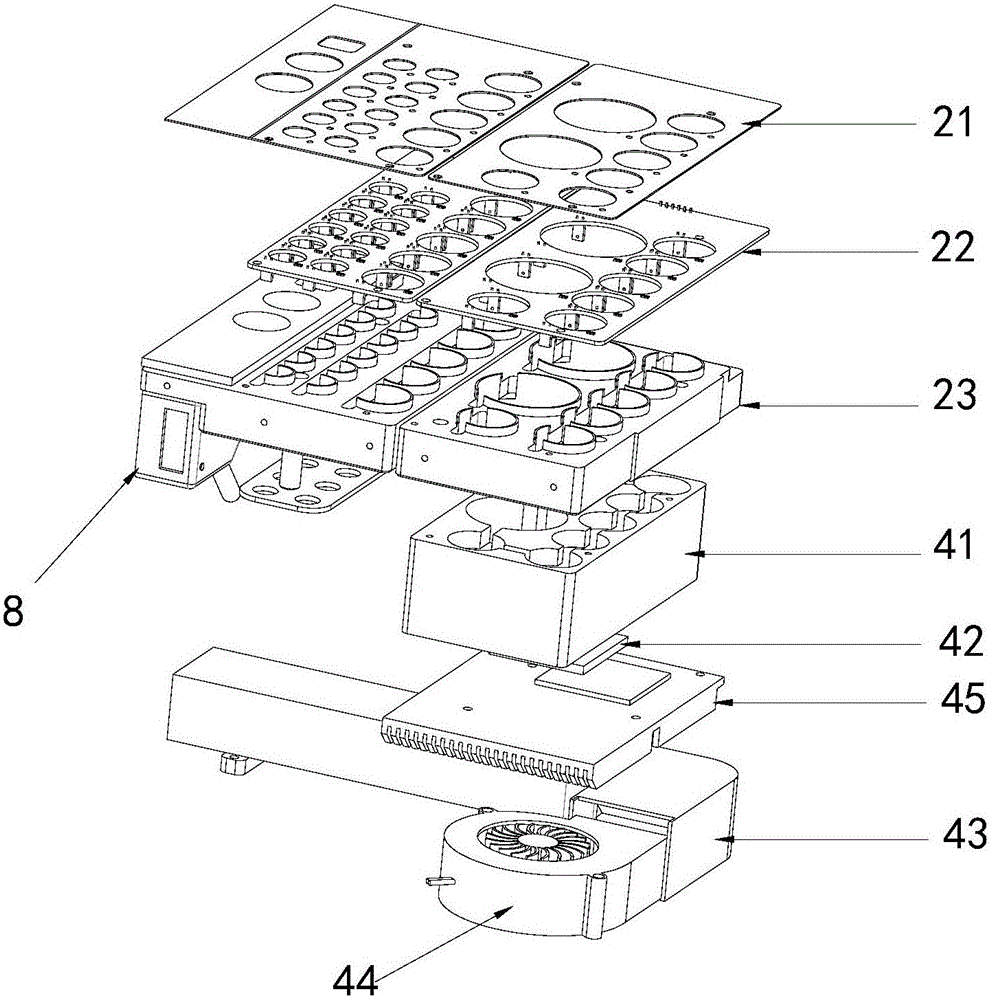

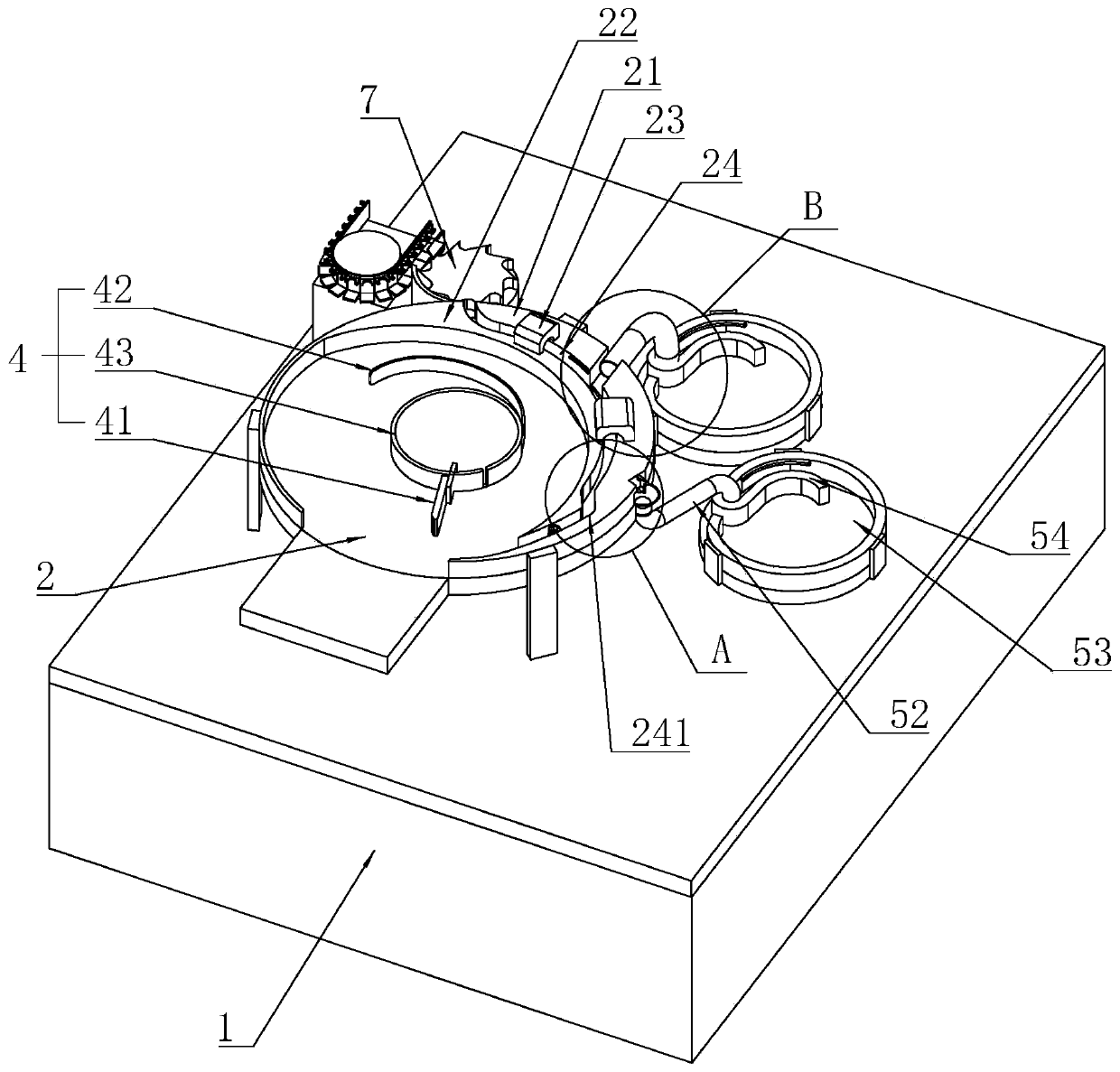

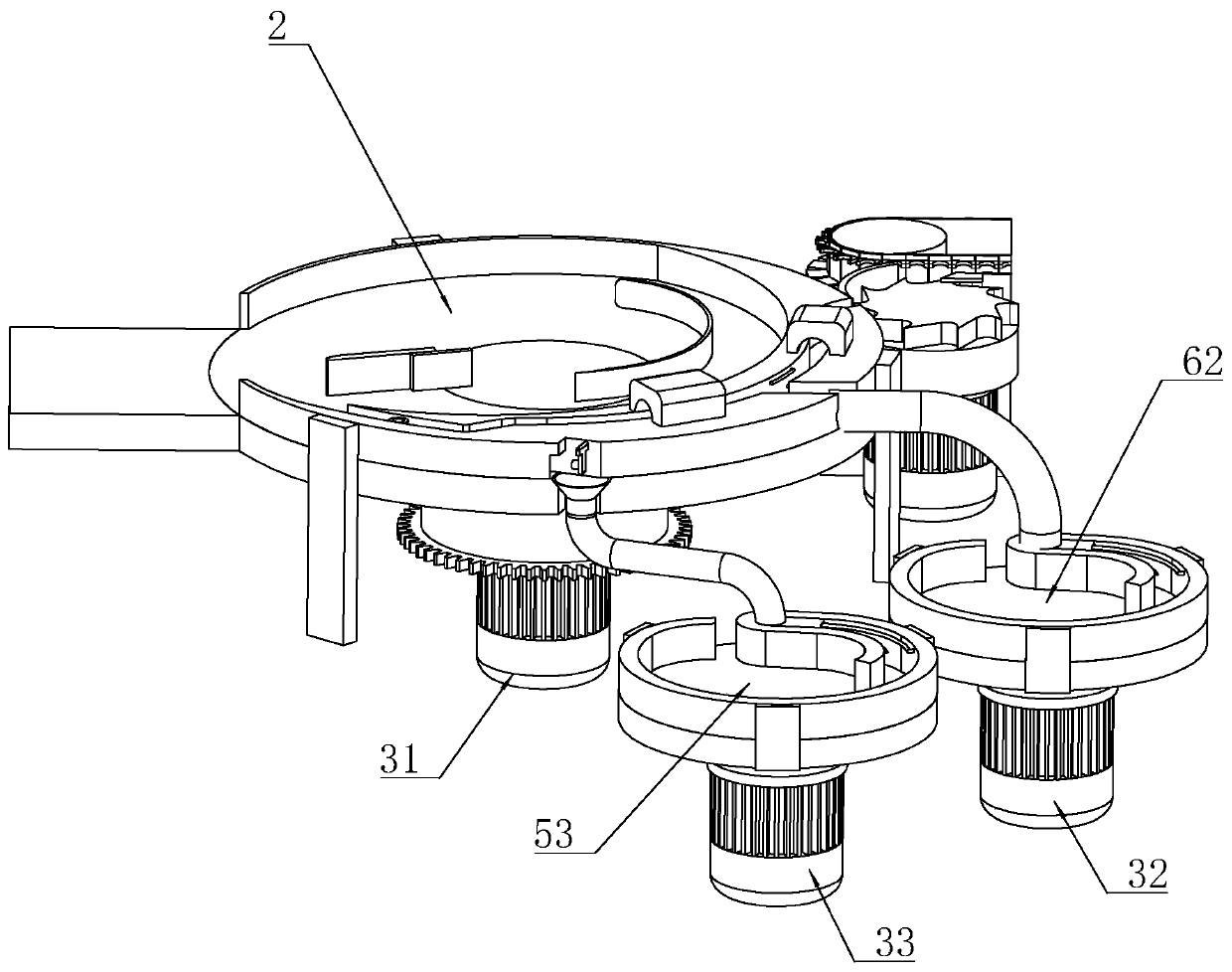

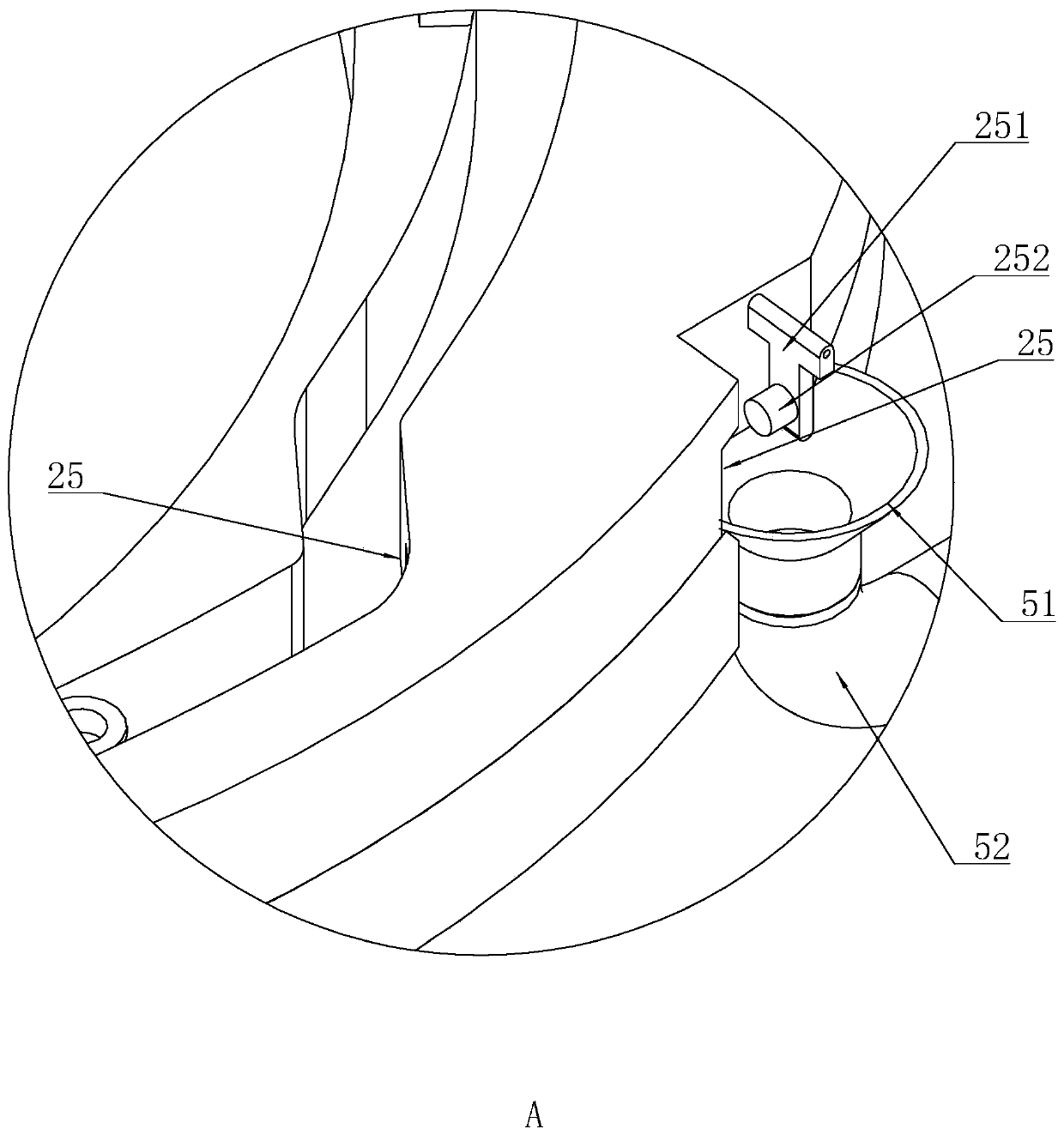

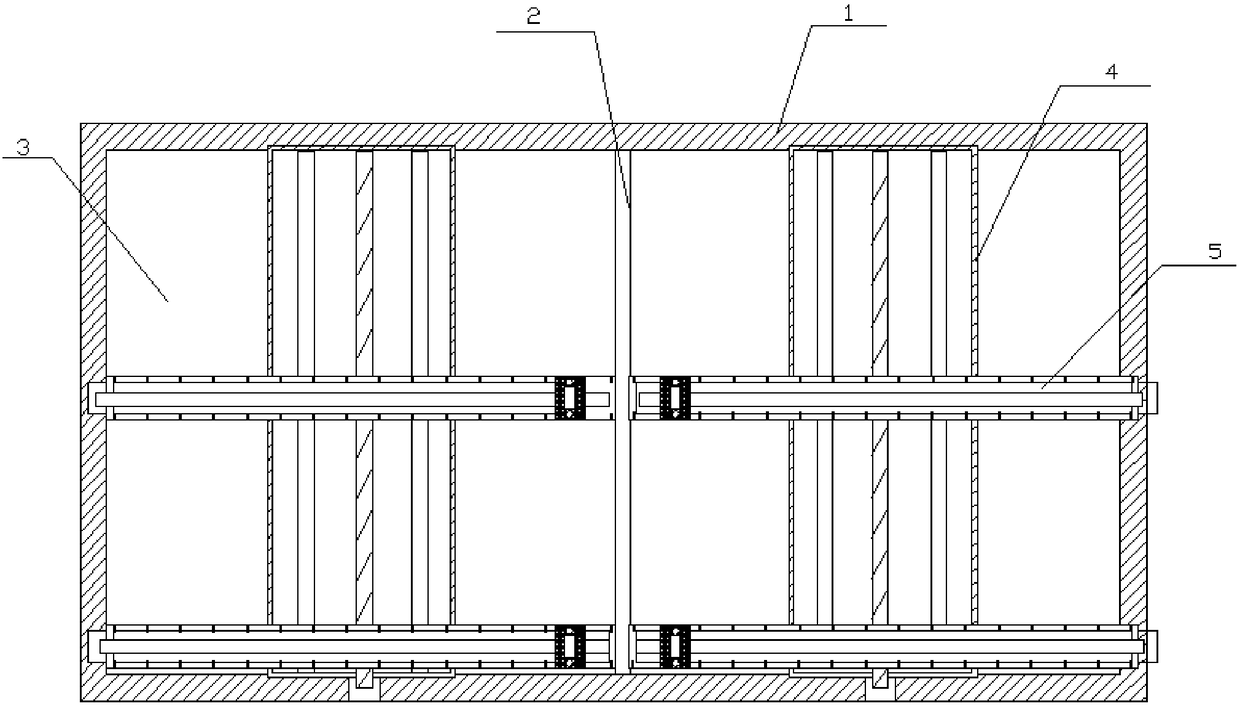

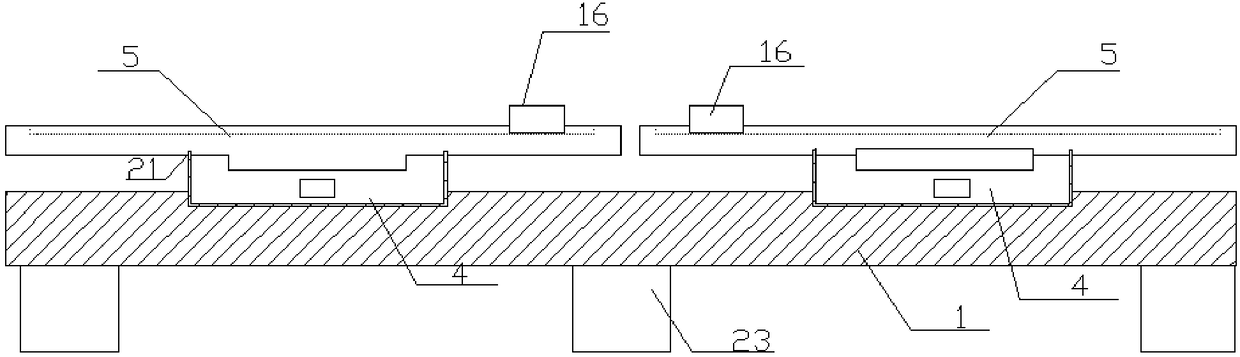

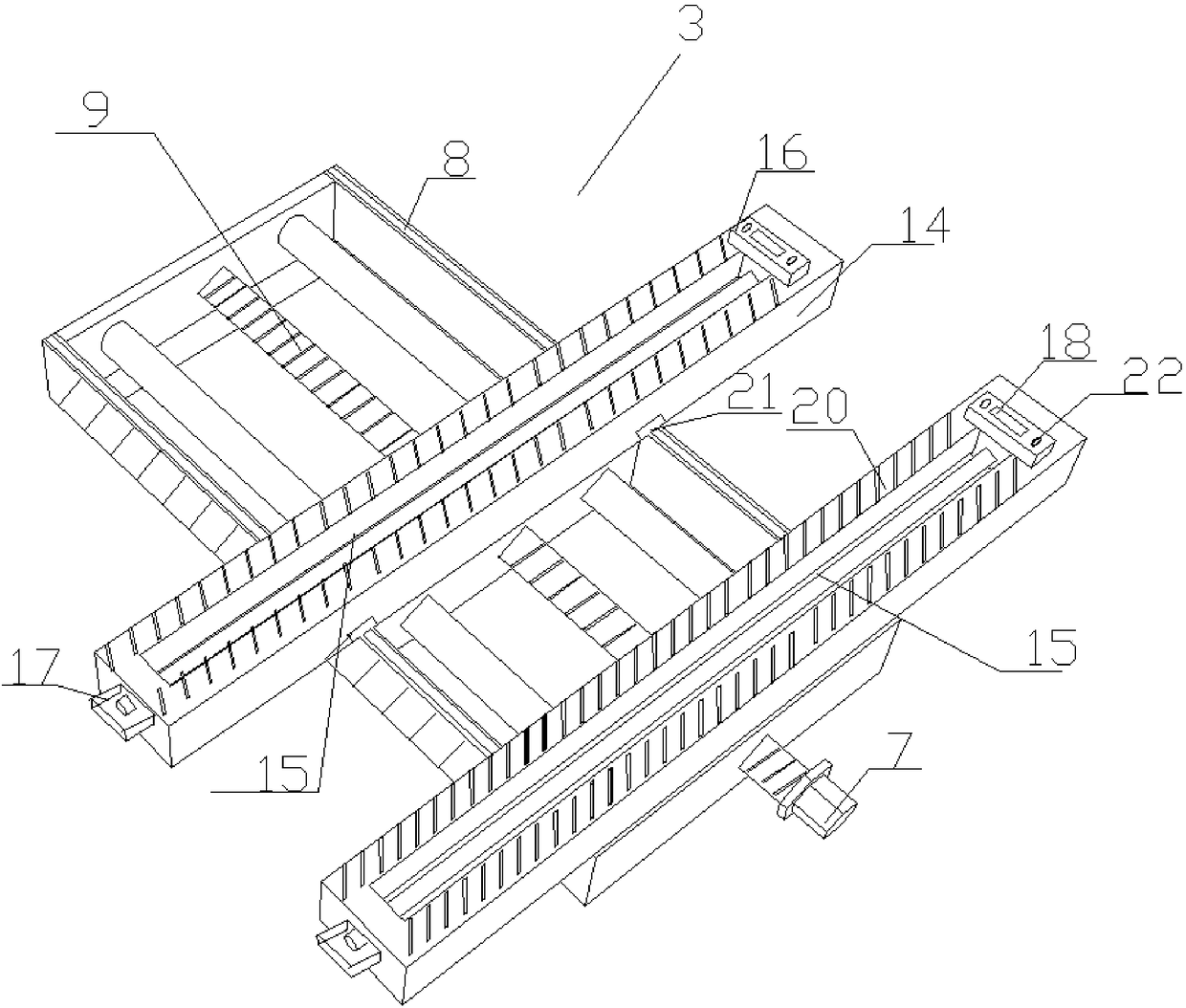

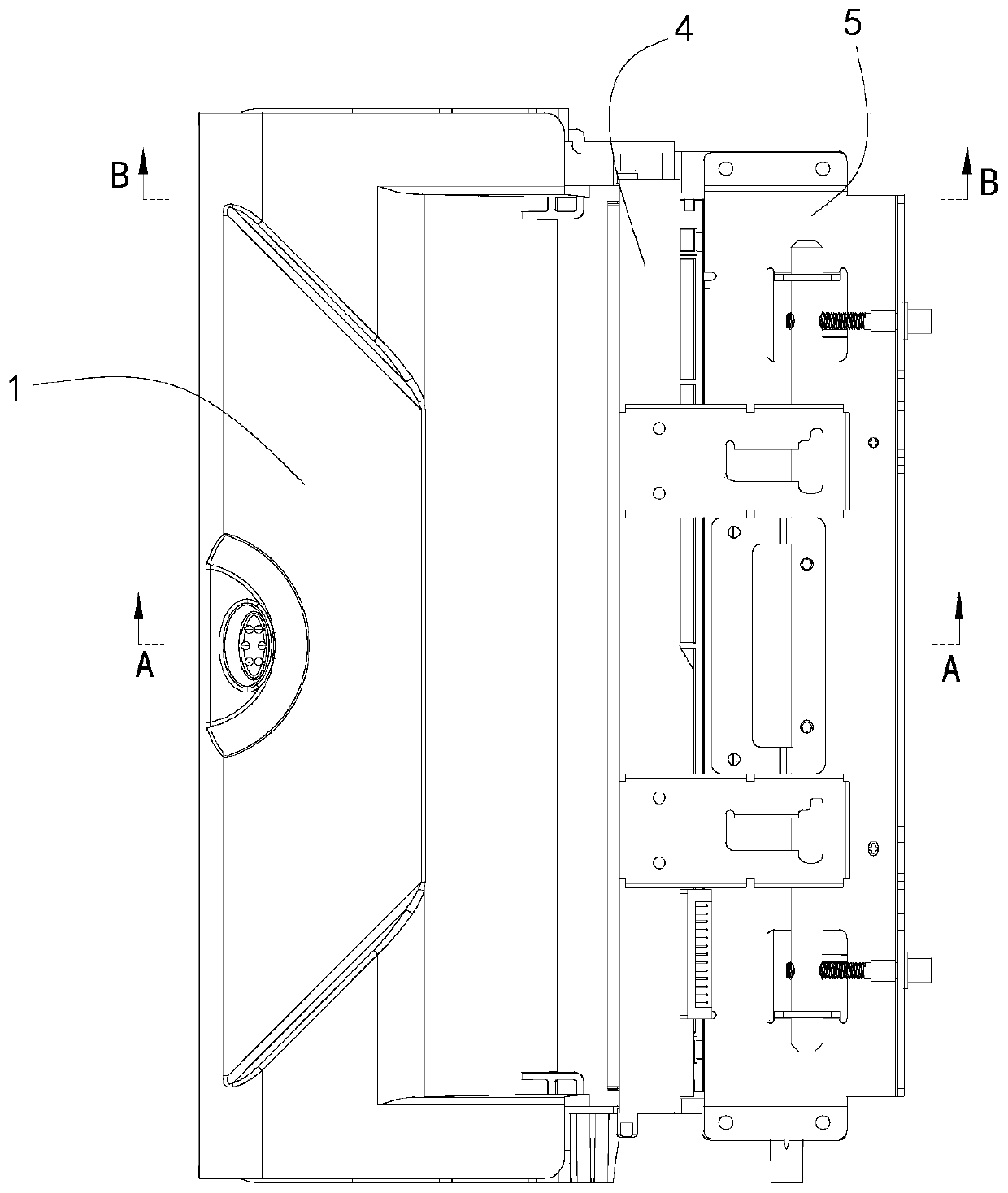

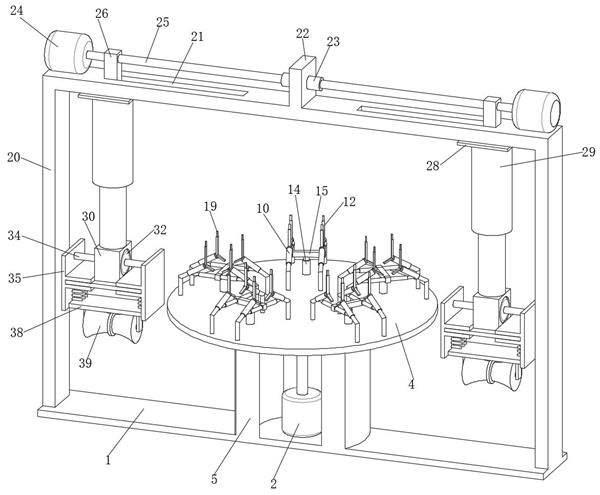

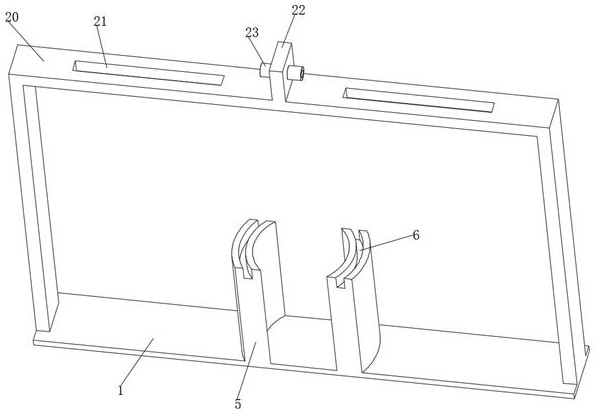

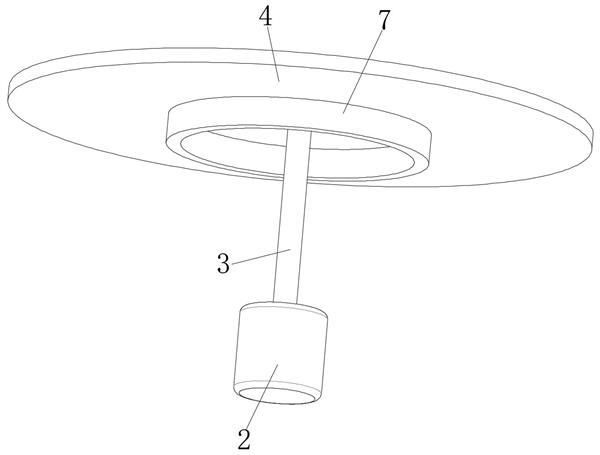

Automatic sorting equipment for strengthening and grinding machining of workpieces

The invention discloses automatic sorting equipment for strengthening and grinding machining of workpieces. The automatic sorting equipment comprises a conveying mechanism used for conveying workpieces, a feeding mechanism used for automatically sending workpieces obtained after strengthening and grinding machining to the conveying mechanism, a detection mechanism used for detecting workpieces anda removing mechanism used for removing unqualified workpieces. The conveying mechanism comprises a first conveying mechanism body and a second conveying mechanism body. The detection mechanism comprises a visual detection mechanism arranged on the first conveying mechanism body and an eddy current detection mechanism arranged on the second conveying mechanism body. The removing mechanism comprises a first removing mechanism body for removing unqualified workpieces detected by the visual detection mechanism and a second removing mechanism body used for removing unqualified workpieces detectedby the eddy current detection mechanism. The automatic sorting equipment can carry out sorting on strengthened and ground workpieces in a full-automatic manner and has the beneficial effects of beinghigh in working efficiency, high in sorting precision and the like.

Owner:GUANGZHOU UNIVERSITY

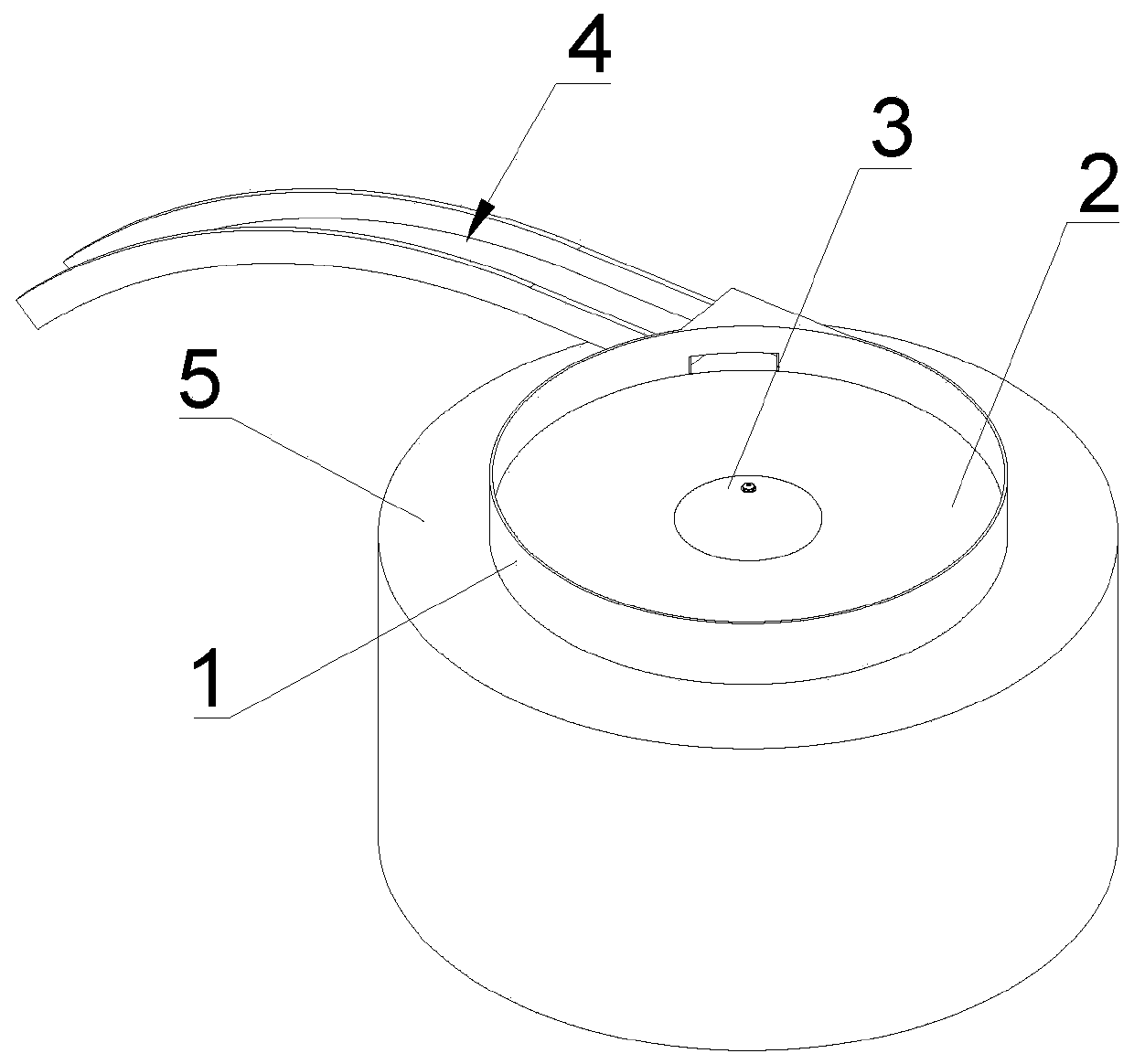

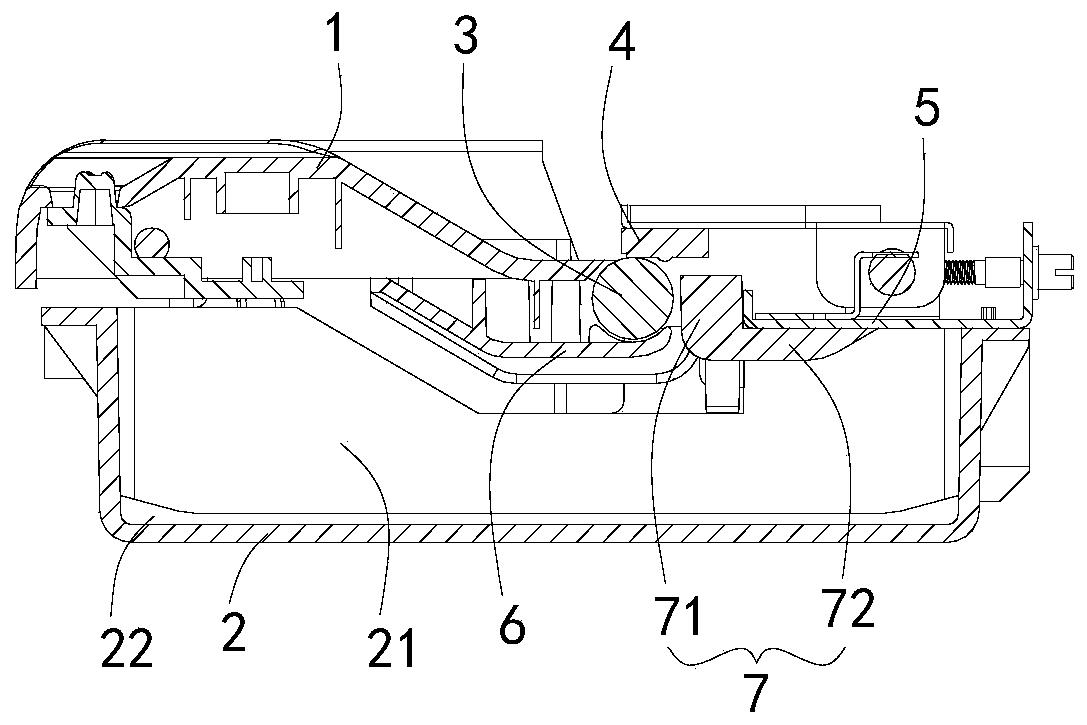

Full-automatic hemostasis examination analyzer and method

ActiveCN105759066ASimple structureCompact structureMaterial analysis by optical meansEngineeringFully automatic

The invention provides a full-automatic hemostasis examination analyzer and a method.The analyzer comprises a box, a sample adding module, a cleaning module, a detecting module and an analyzing module; the detecting module comprises a microfluidic control disc, a motor, a light source, a detector, a heating part, a bracket and a slip cover, the microfluidic control disc is provided with an injection opening, a reaction groove and a detection cavity, the motor is used for driving the disc to rotate, the light source is used for emitting measurement light, the detector is used for converting the measurement light absorbed by a sample in the detection cavity into electrical signals and sending the electrical signals to the analyzing module, the heating part is used for heating the microfluidic control disc, guide rails are arranged on the bracket, the microfluidic control disc and the motor are installed on the bracket, and the slip cover is arranged on the guide rails and shields the microfluidic control disc when moving.The hemostasis examination analyzer has the advantages of being simple in structure, fully automatic and the like.

Owner:ZHEJIANG PUSHKANG BIOTECHNOLOGY CO LTD

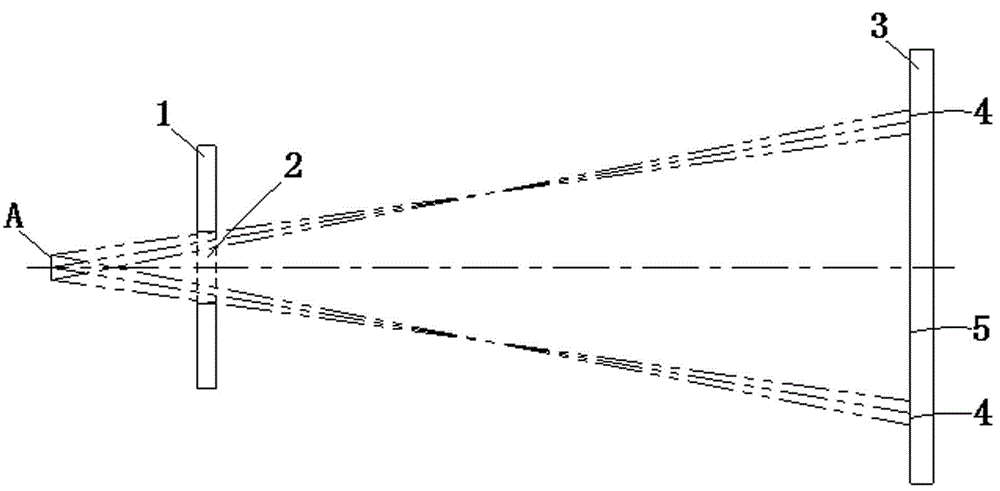

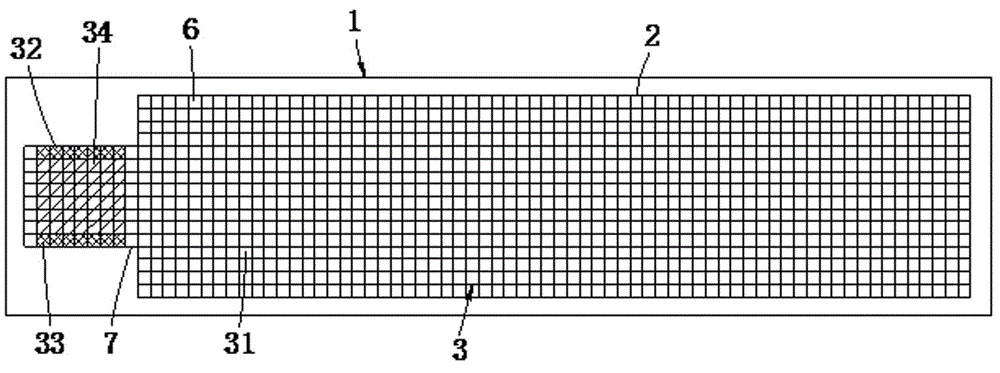

Detector device with Z-axis focus tracing and correction capacity and application method thereof

The invention relates to a detector device with Z-axis focus tracing and correction capacity and an application method thereof. The detector device comprises an X ray emission source, a front collimator and a detector, collimation holes are formed in the front collimator, the front collimator is further provided with tracing holes, X rays can pass through the tracing holes, the tracing holes are symmetrical about the symmetric lines of the collimation holes, and the side faces of the tracing holes are communicated with the side faces of the collimation holes. The detector is mainly divided into an ideal attention channel region, an upper reference channel region, a lower reference channel region and a baseline channel region, the ideal attention channel region receives X rays passing through the collimation holes, the lower reference channel region is located on the lower side of the baseline channel region, and the upper reference channel region, the lower reference channel region and the baseline channel region are used for receiving X rays passing through the tracing holes. According to the detector device and the application method thereof, Z-axis focus tracing and correction are conducted more simply and conveniently, cost is effectively reduced, and economic benefits are increased.

Owner:FMI MEDICAL SYST CO LTD

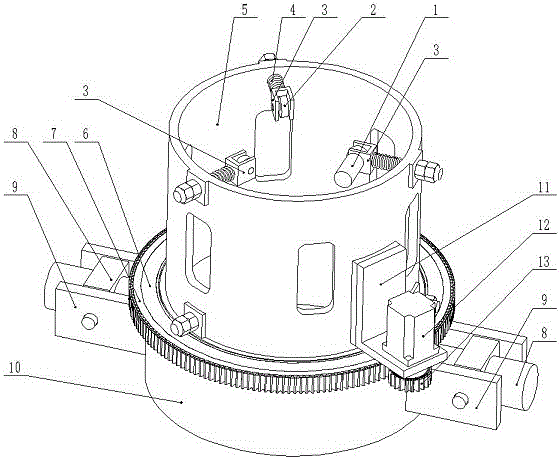

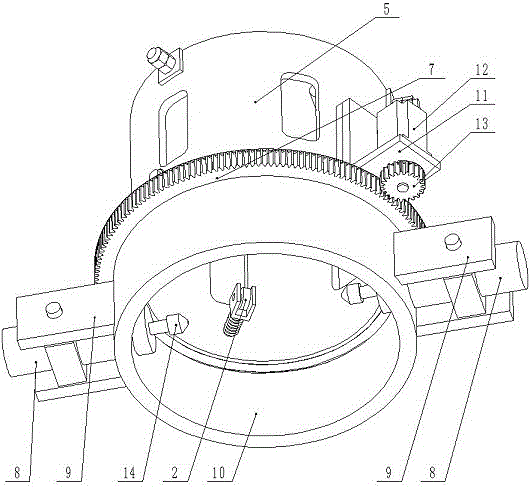

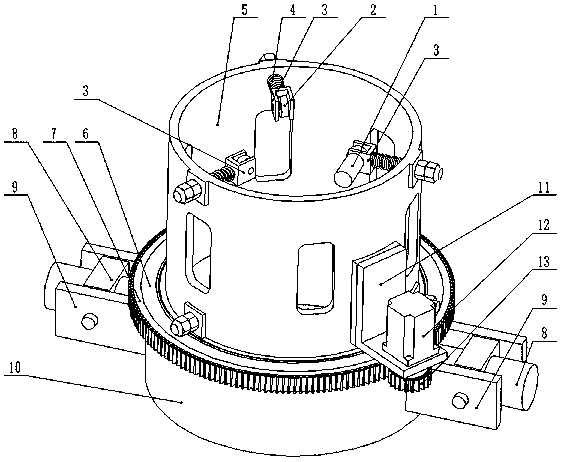

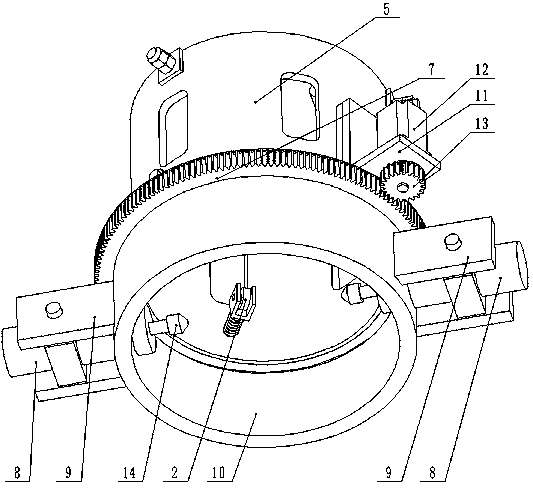

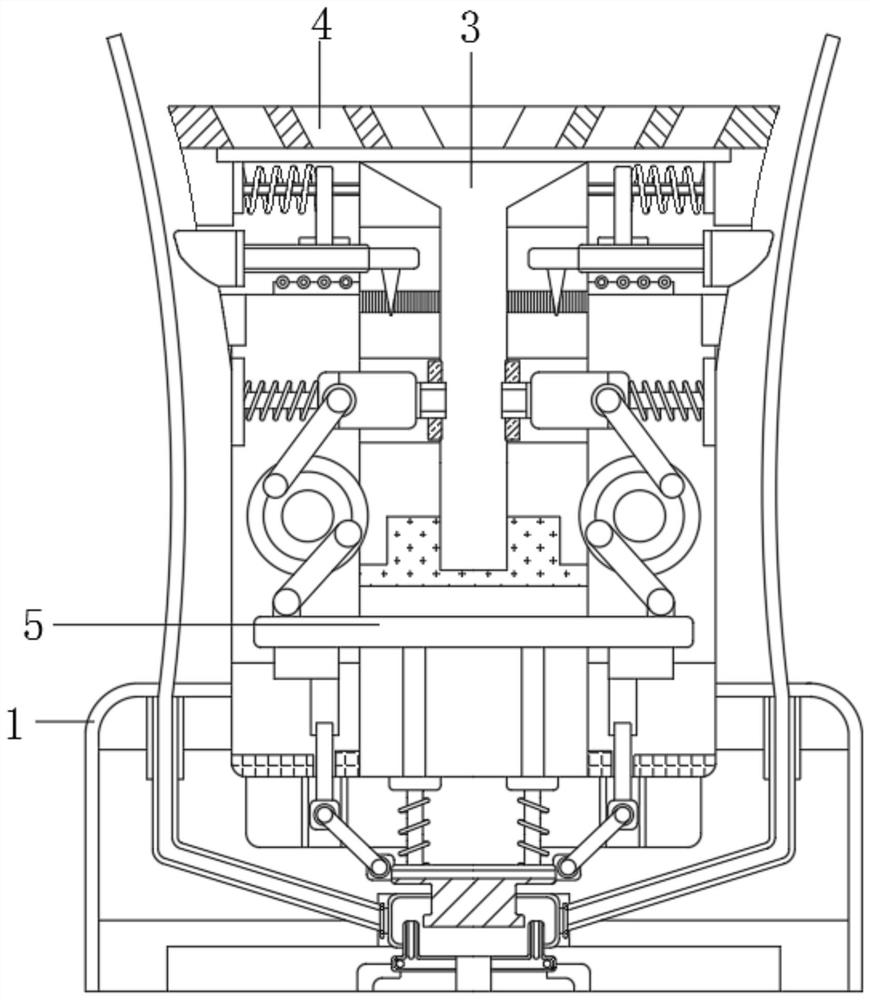

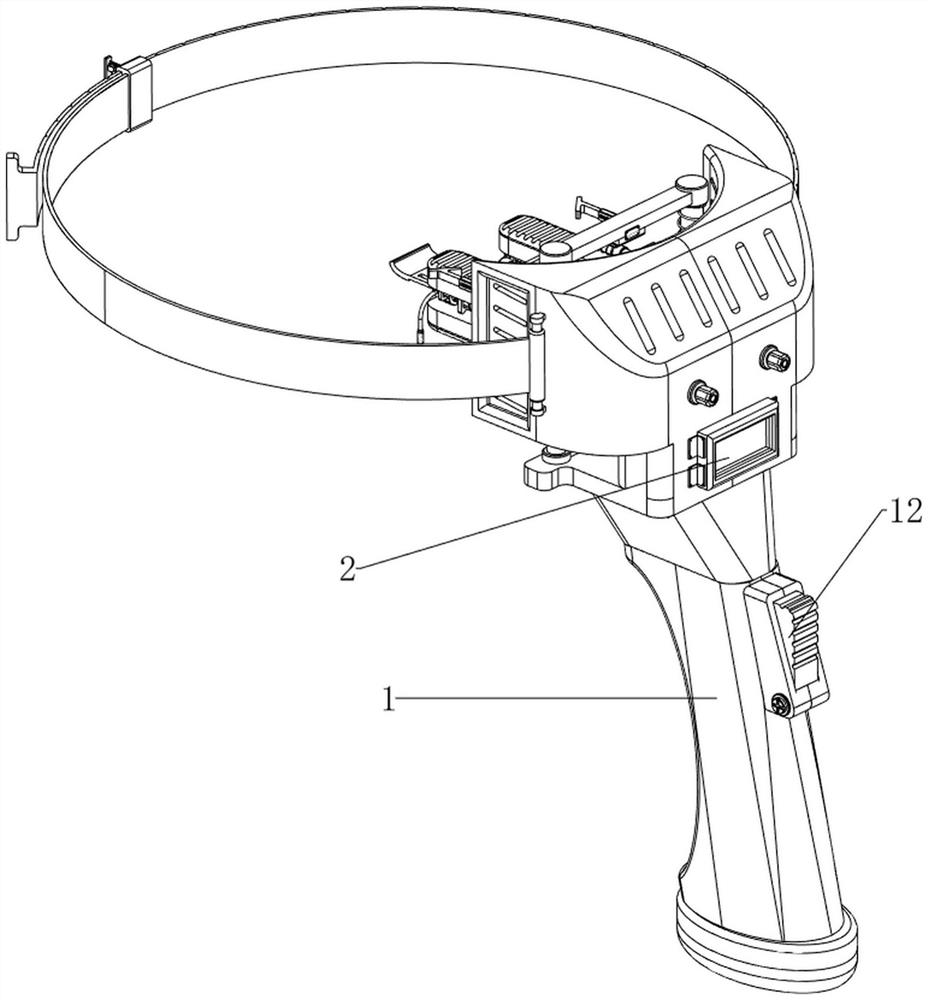

Steel pipe automatic correction robot

The invention discloses a steel pipe automatic correction robot which comprises an annular main rack, a rotating rack, a rotating bearing, a large gear and a small gear, wherein six roller mounting racks are respectively and slidingly mounted on six mounting shafts; six rollers are respectively and rotationally mounted on the six roller mounting racks; two roller motors are respectively mounted on a roller mounting rack at the lower part of and a roller mounting rack at the upper part of the annular main rack; a rotating motor mounting rack is mounted at the external periphery of the annular main rack; a rotating motor is mounted on the rotating motor mounting rack; the rotating bearing is coaxially mounted at the lower part of the annular main rack; the large gear is coaxially mounted on the rotating bearing; cylinder bodies of two hydraulic cylinders are respectively mounted on two hydraulic cylinder mounting racks; piston rods of the two hydraulic cylinders respectively stretch into the rotating rack; and pressing head jacking blocks are mounted at the end parts of the piston rods. Through the arrangement of the automatic rollers and the rotating rack, the purpose of correcting a steel pipe efficiently and automatically is realized. The steel pipe automatic correction robot is simple in structure, low in cost and convenient to operate.

Owner:常熟市创福管业有限公司

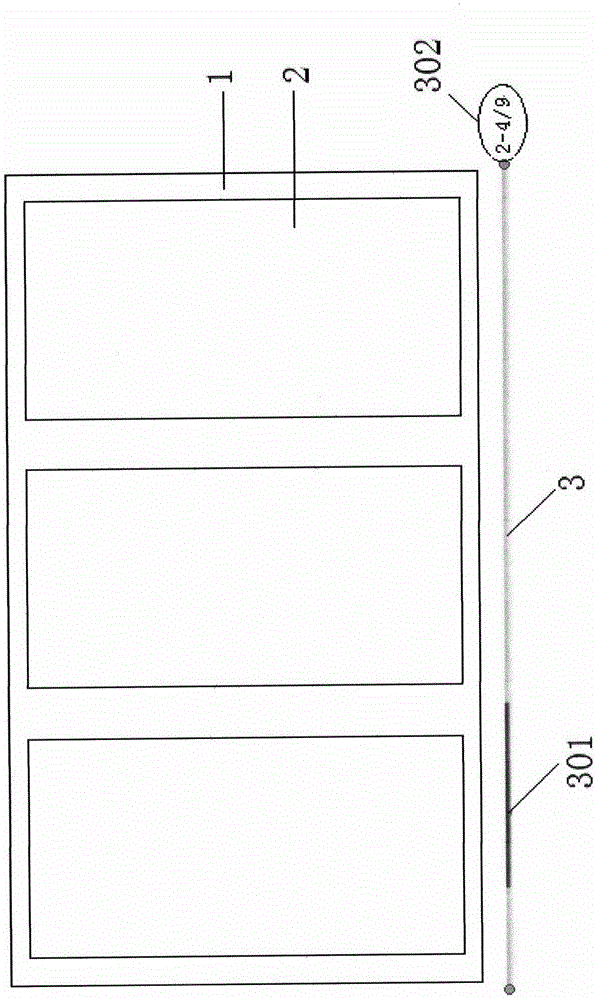

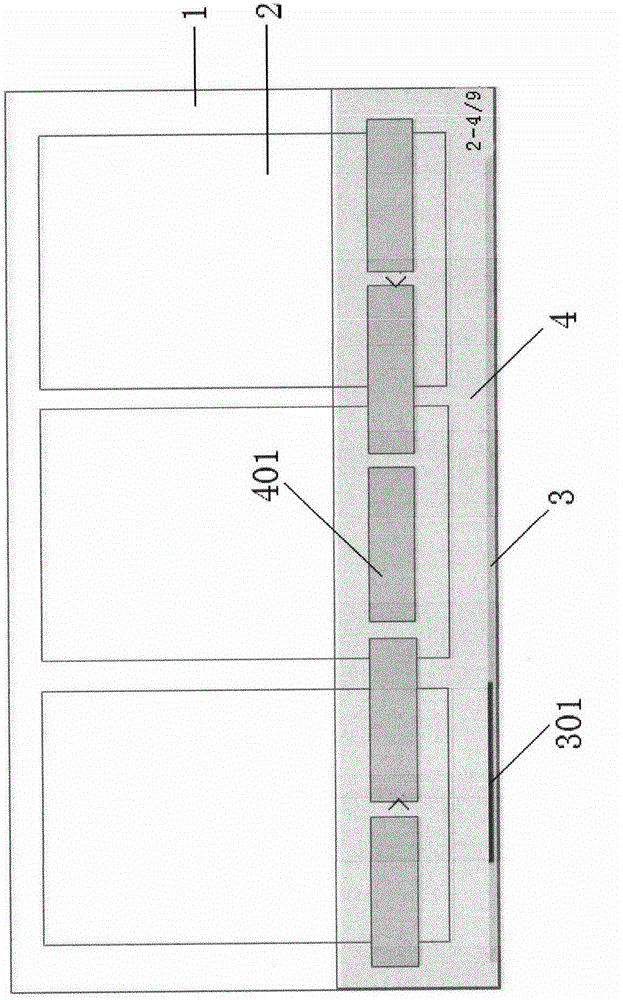

Method for positioning and switching multiple columns or windows

InactiveCN104571828AImplement transposition operationAutomatic correctionInput/output processes for data processingComputer science

Owner:HUNAN ANTVISION SOFTWARE

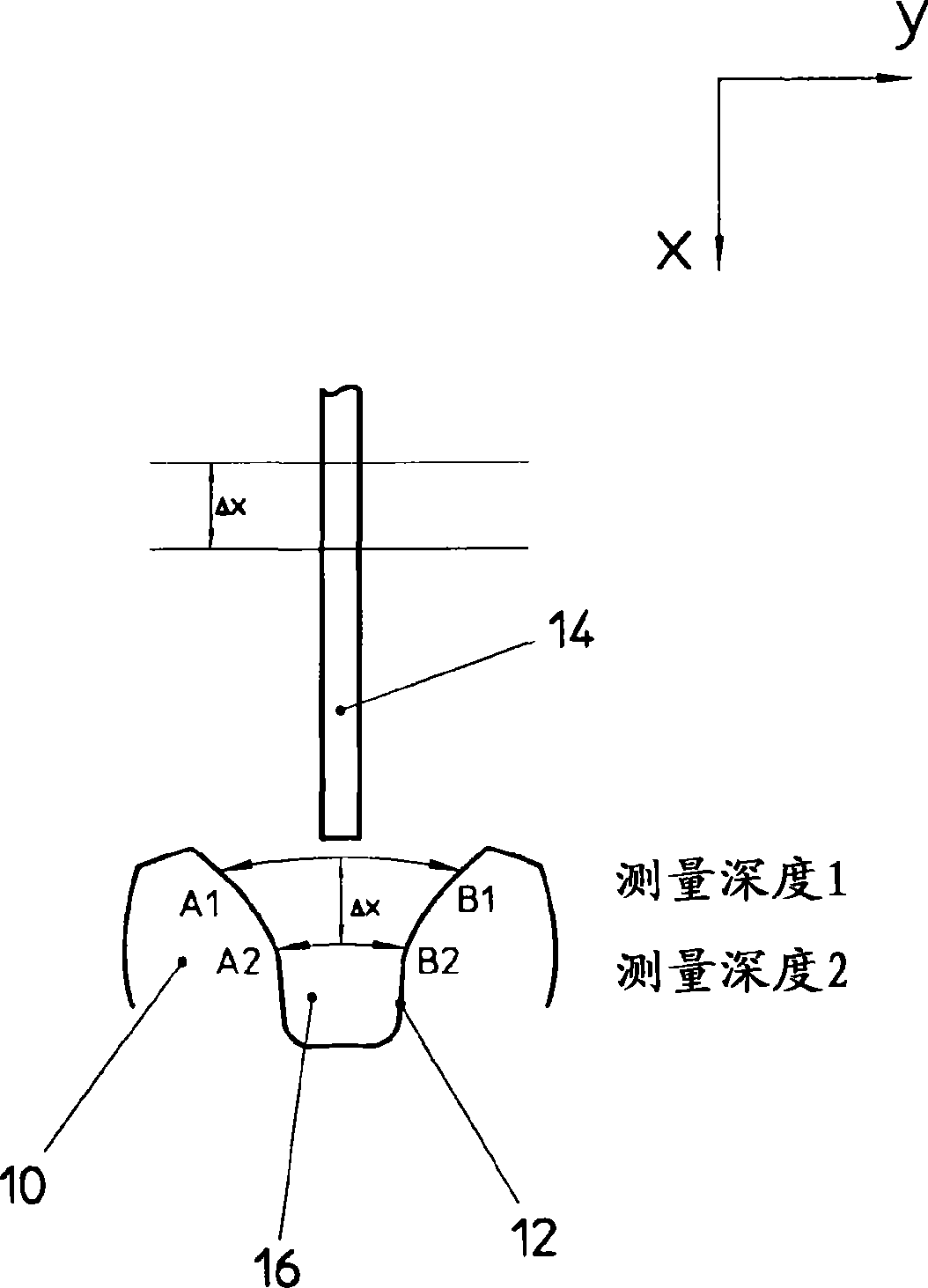

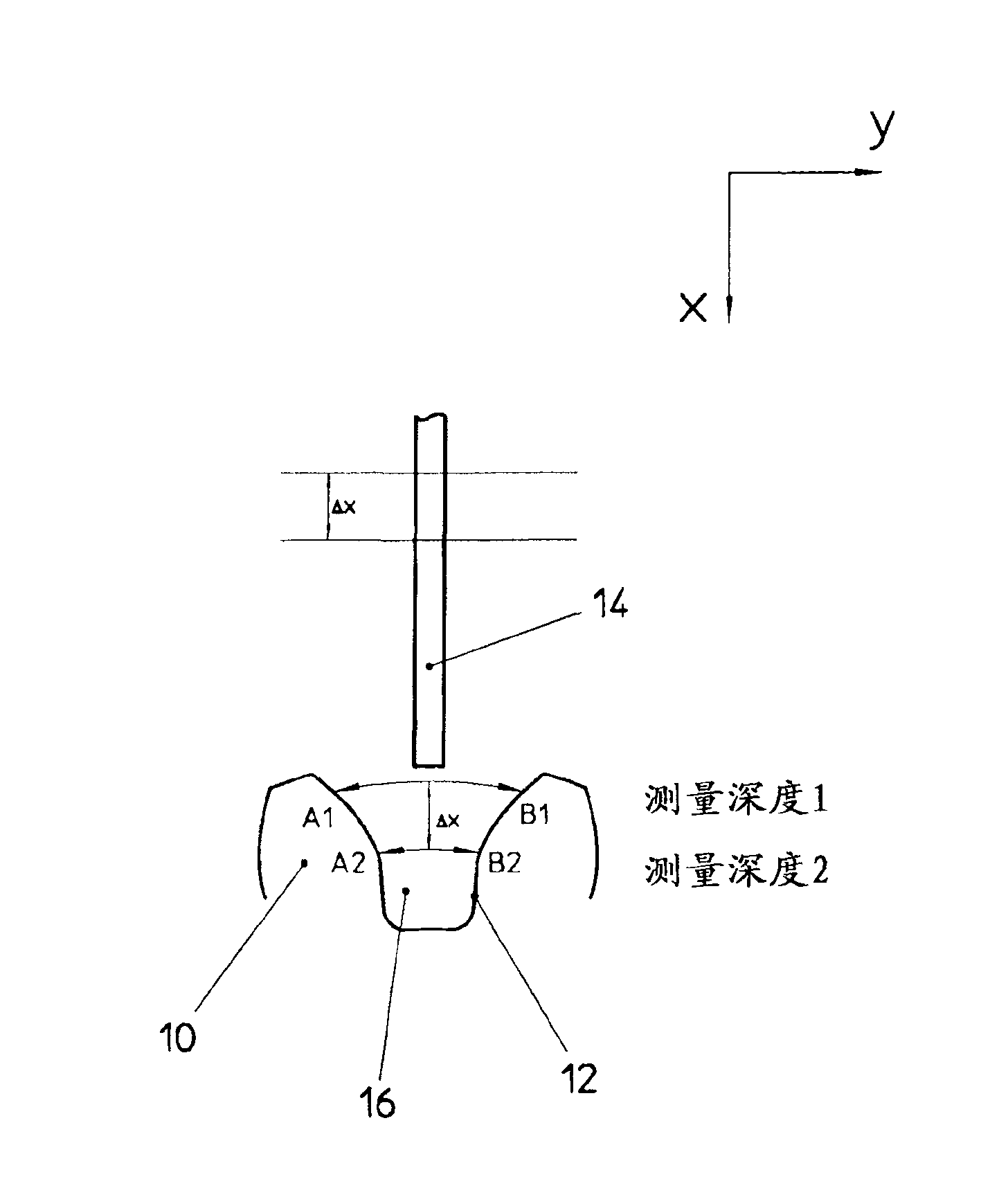

Method for testing gear wheels during their production

InactiveCN101175968ACenter distance error correctionAutomatic correctionMechanical counters/curvatures measurementsGear-cutting machinesGear wheelEngineering

The invention relates to a method for testing gear wheels during their production in a gear cutting machine. According to said method, the tool is driven against the respective workpiece at specific points in order to determine potential deviations. Said deviations are then used to correct the setting of the tool by means of a control loop.

Owner:LIEBHERR VERZAHNTECHNIK GMBH

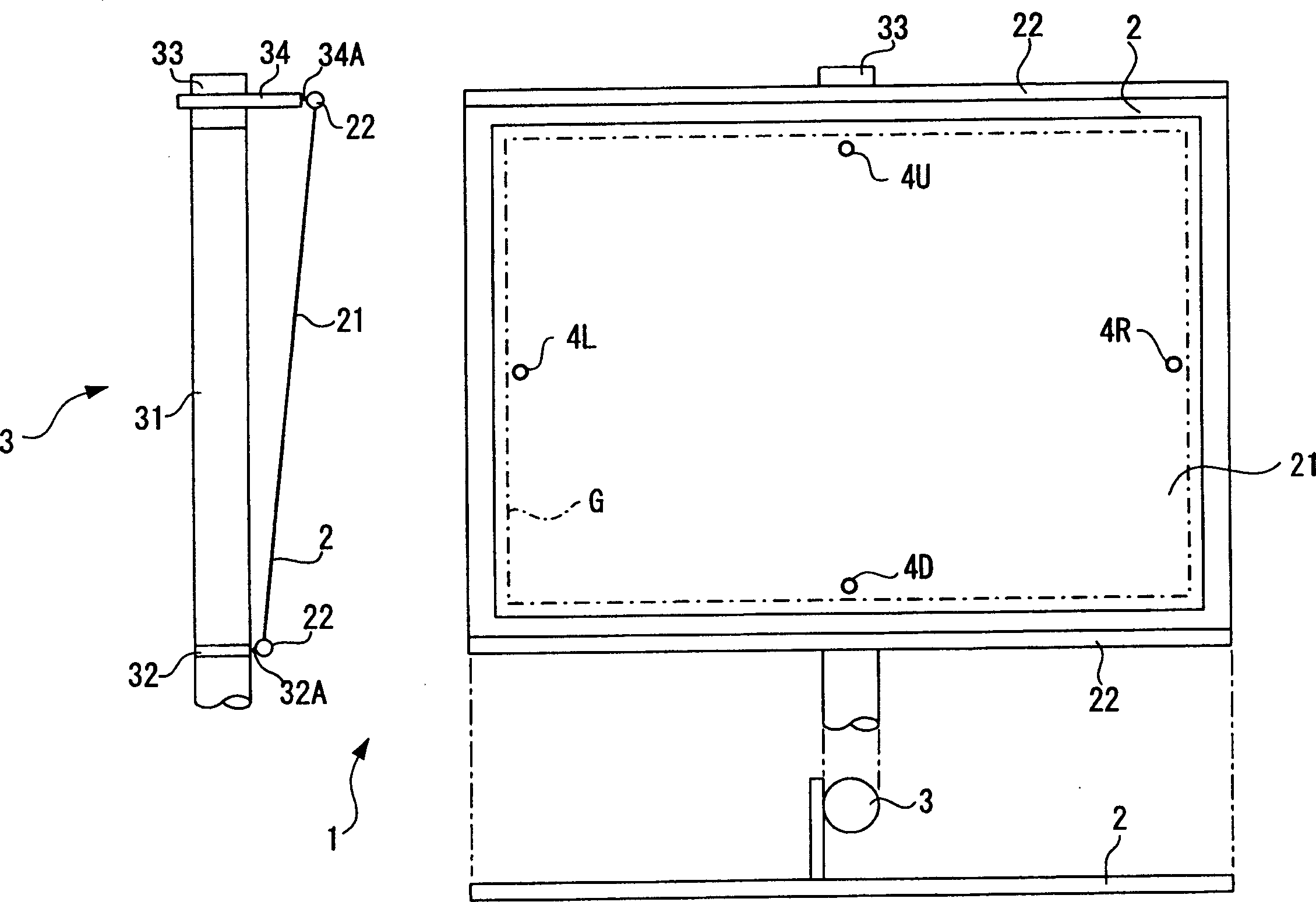

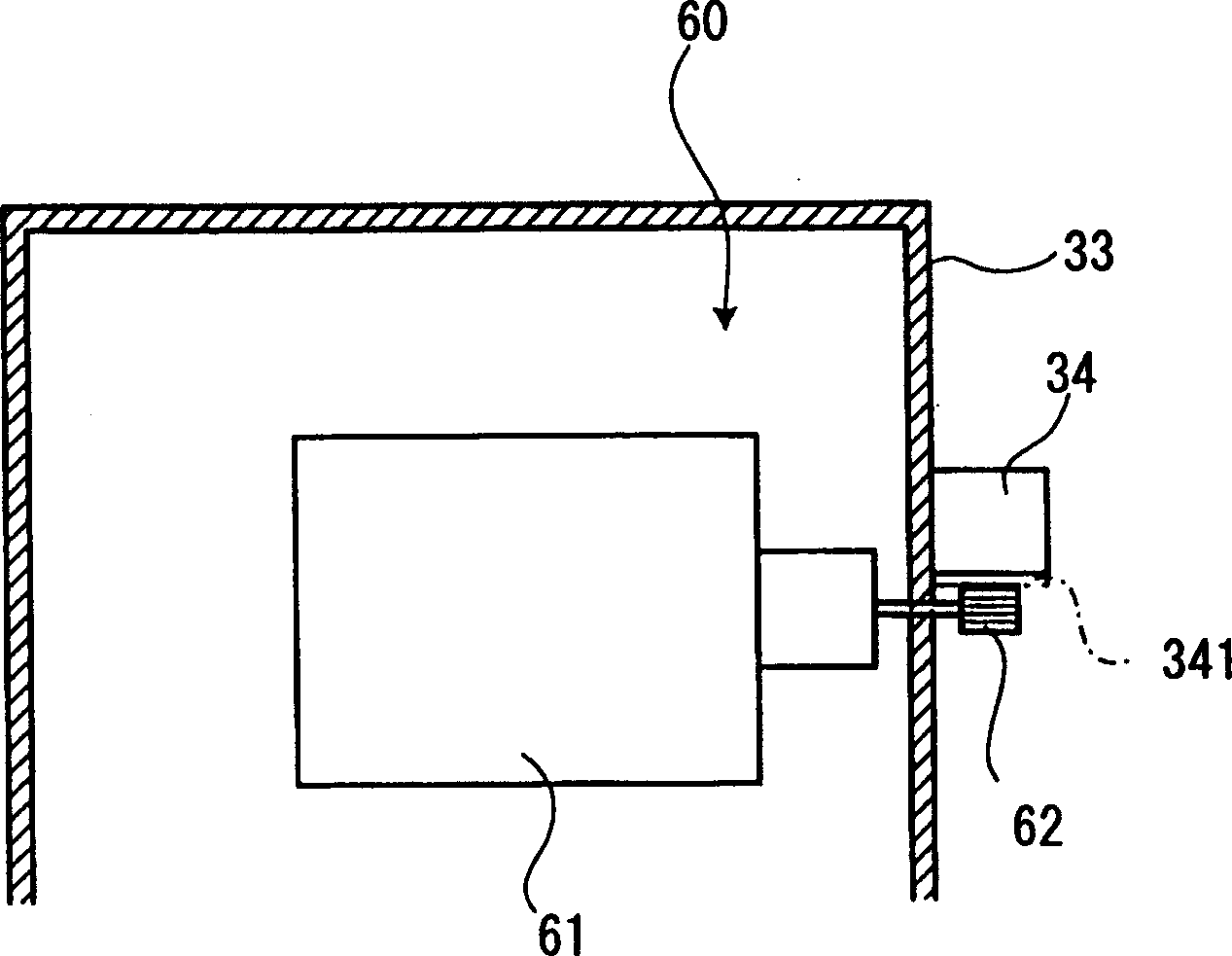

Screen

InactiveCN1469192AAutomatic correctionProjectorsPhotometry using electric radiation detectorsProjection imageLight beam

A screen having a projection surface on which a light beam irradiated by an optical equipment such as a projector is projected to form a projection image has luminous energy sensors (4U, 4D, 4L, 4R) and an attitude controller (70) for controlling the attitude of the projection surface based on the luminous energy detected by the luminous energy sensors (4U, 4D, 4L, 4R), in which, since the luminous energy sensors (4U, 4D, 4L, 4R) and the attitude controller (70) are provided, the attitude of the projection surface can be controllably adjusted by detecting the luminous energy of the projection image from the optical equipment, so that the projection surface of the screen can be correctly positioned relative to the optical equipment, thus automatically correcting trapezoidal distortion etc. of the projection image.

Owner:SEIKO EPSON CORP

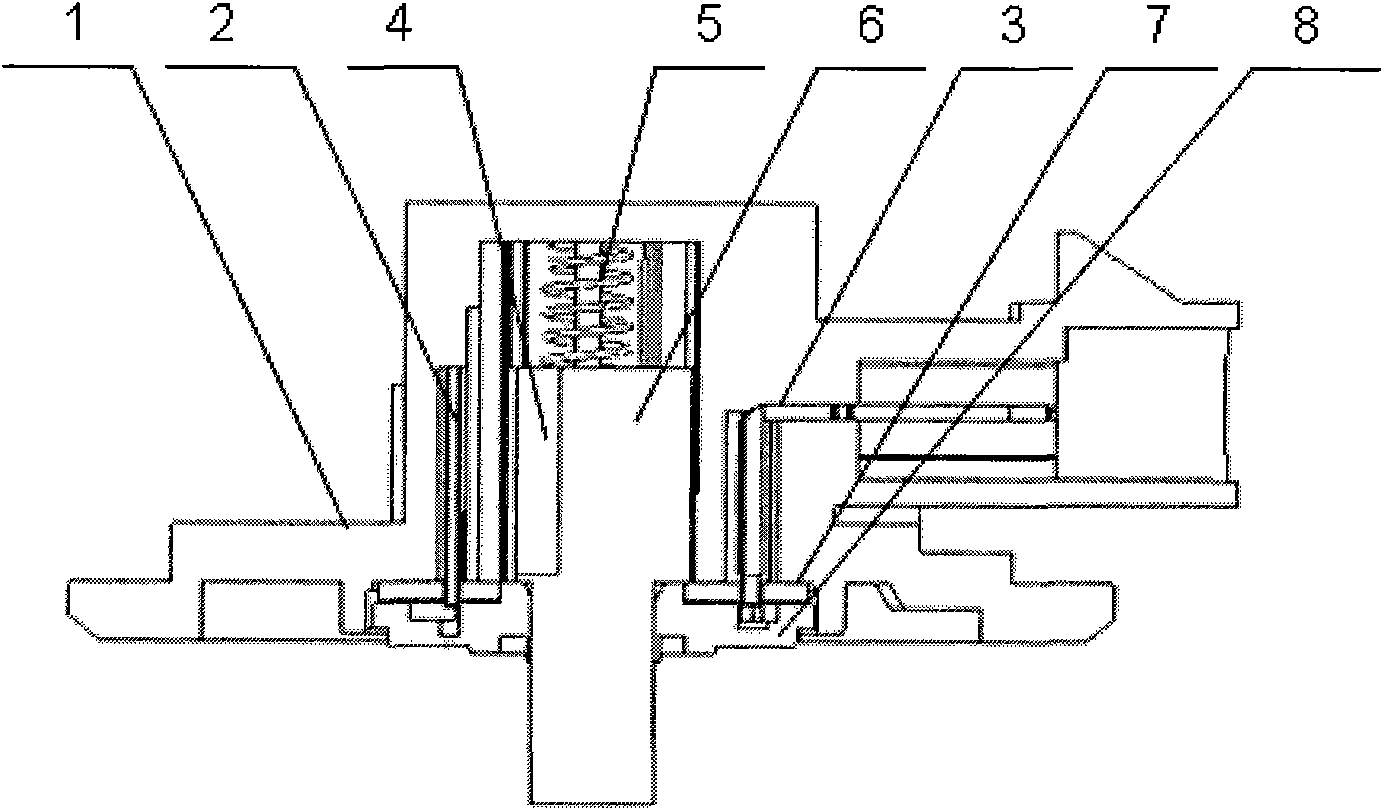

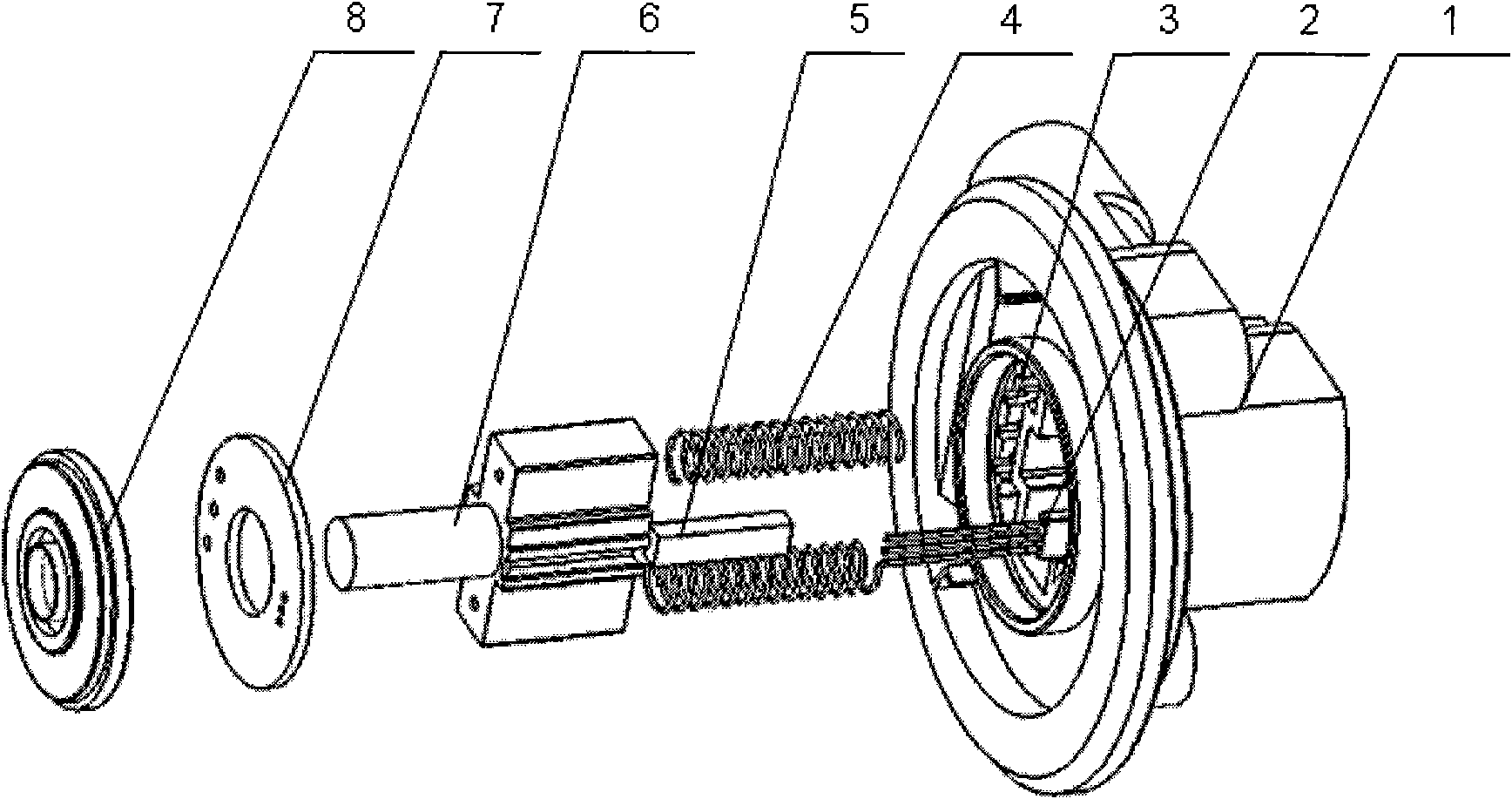

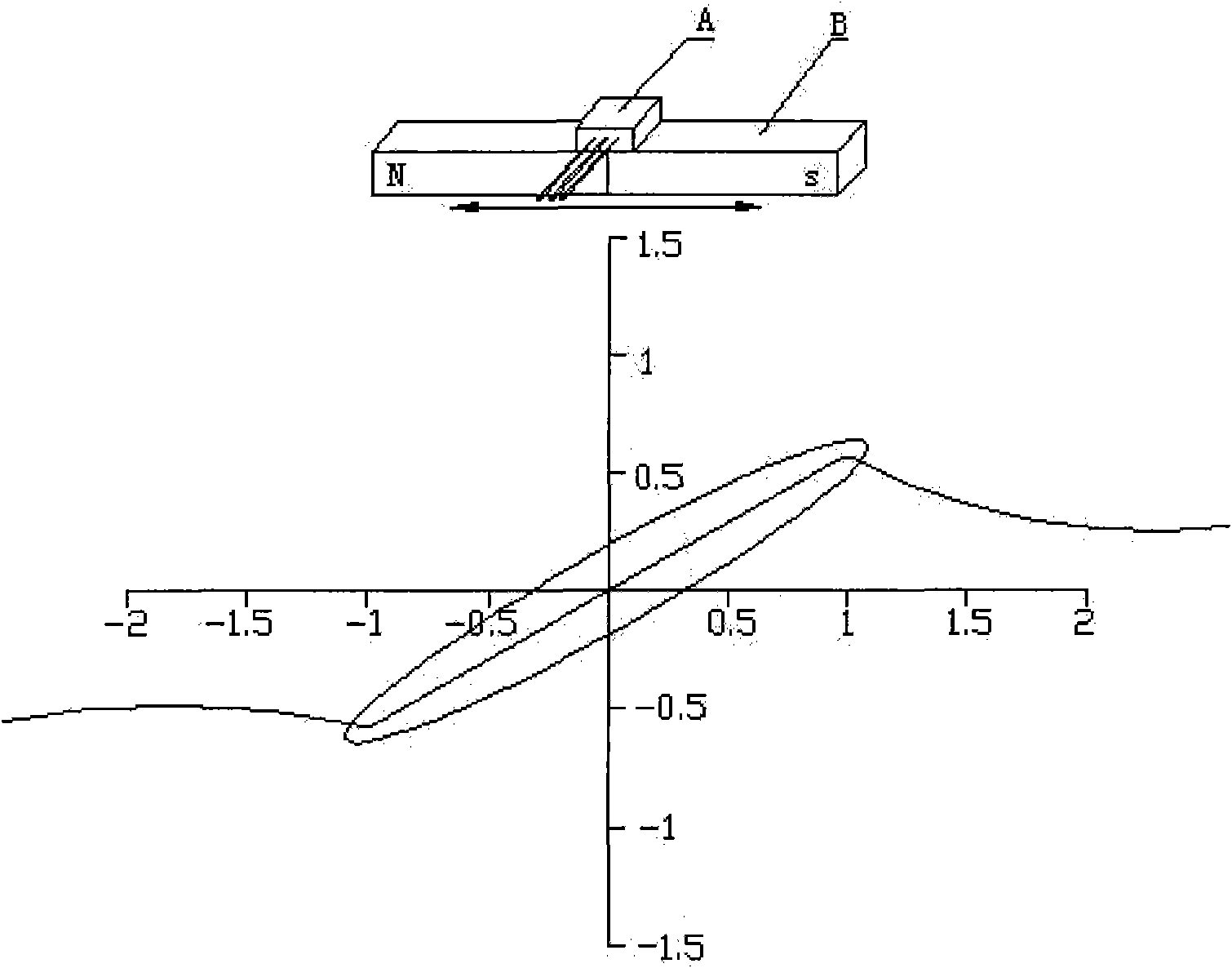

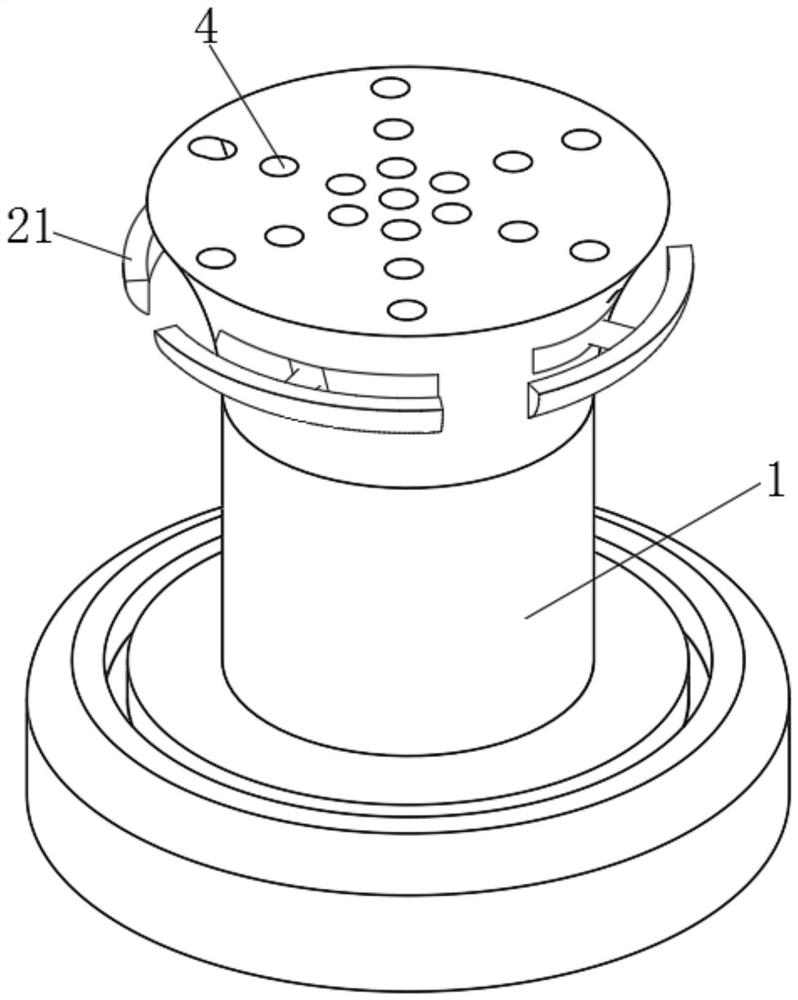

Noncontact-type EGR (Exhaust Gas Recirculation) valve position sensor

InactiveCN101865647AExtend working lifeSolve contact wearNon-fuel substance addition to fuelInternal combustion piston enginesElectrical conductorHall element

The invention relates to a noncontact-type EGR (Exhaust Gas Recirculation) valve position sensor. The sensor is provided with a hat-shaped shell, a guide pole is arranged in a blind hole in the middle of the shell, the other end of the guide pole extends outwards, a pull-back spring is arranged between the guide pole and the bottom of the blind hole of the shell, a magnet block is arranged on the upper lateral surface of the guide pole, a circular circuit board is sleeved at the lower part of the guide pole, and a hall chip is welded on the circuit board through conductor pins in a straight bar shape and arranged in the blind hole at the magnet block side of the shell. The invention is used for solving the problem of contact abrasion of the sensor and has greatly prolonged working service life, favorable linear transmission characteristics and more accurately and stably output signals. When a hall element axially moves along the lateral surface of the magnet block, and a linearly-variable magnetic field can present in a certain displacement range, is linearly converted by the hall chip and finally outputs a linearly-variable voltage. The invention achieves the linear output requirement of the EGR position sensor by utilizing the favorable linearity characteristic in the region.

Owner:HEFEI BANGLI ELECTRONICS

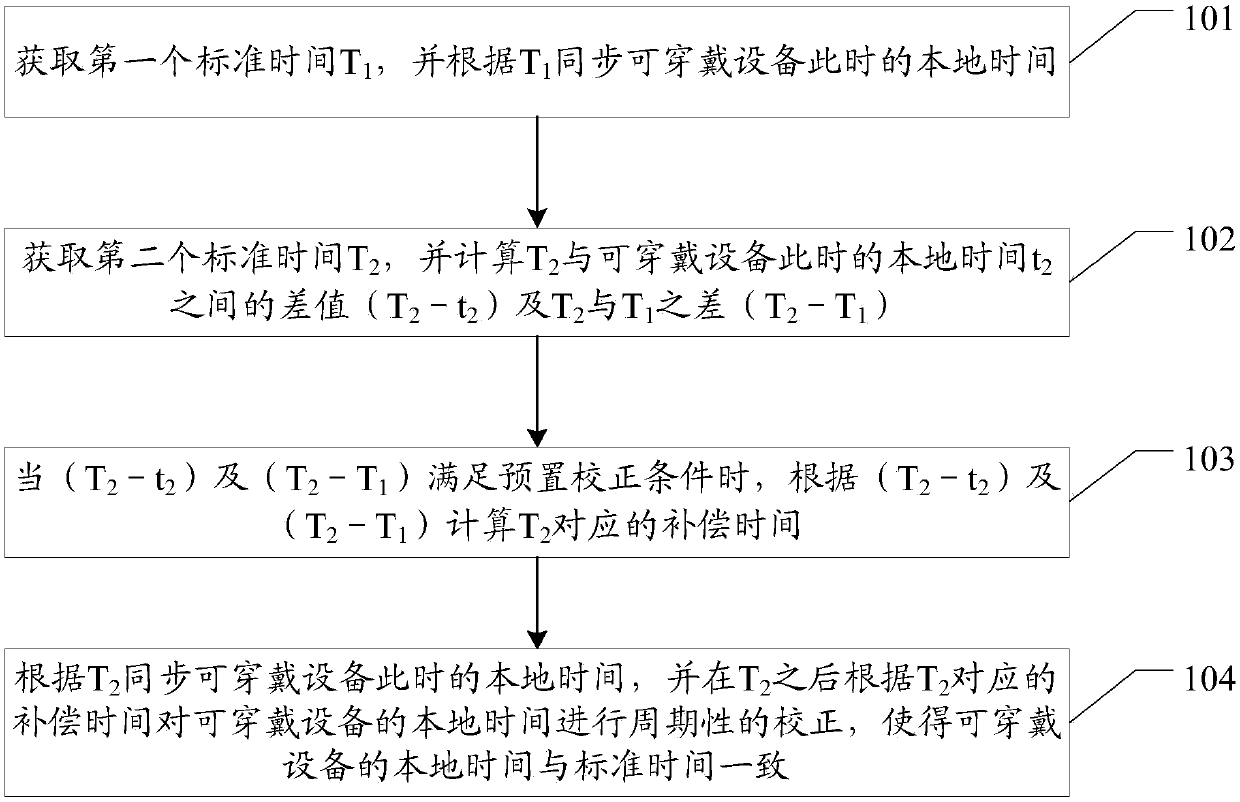

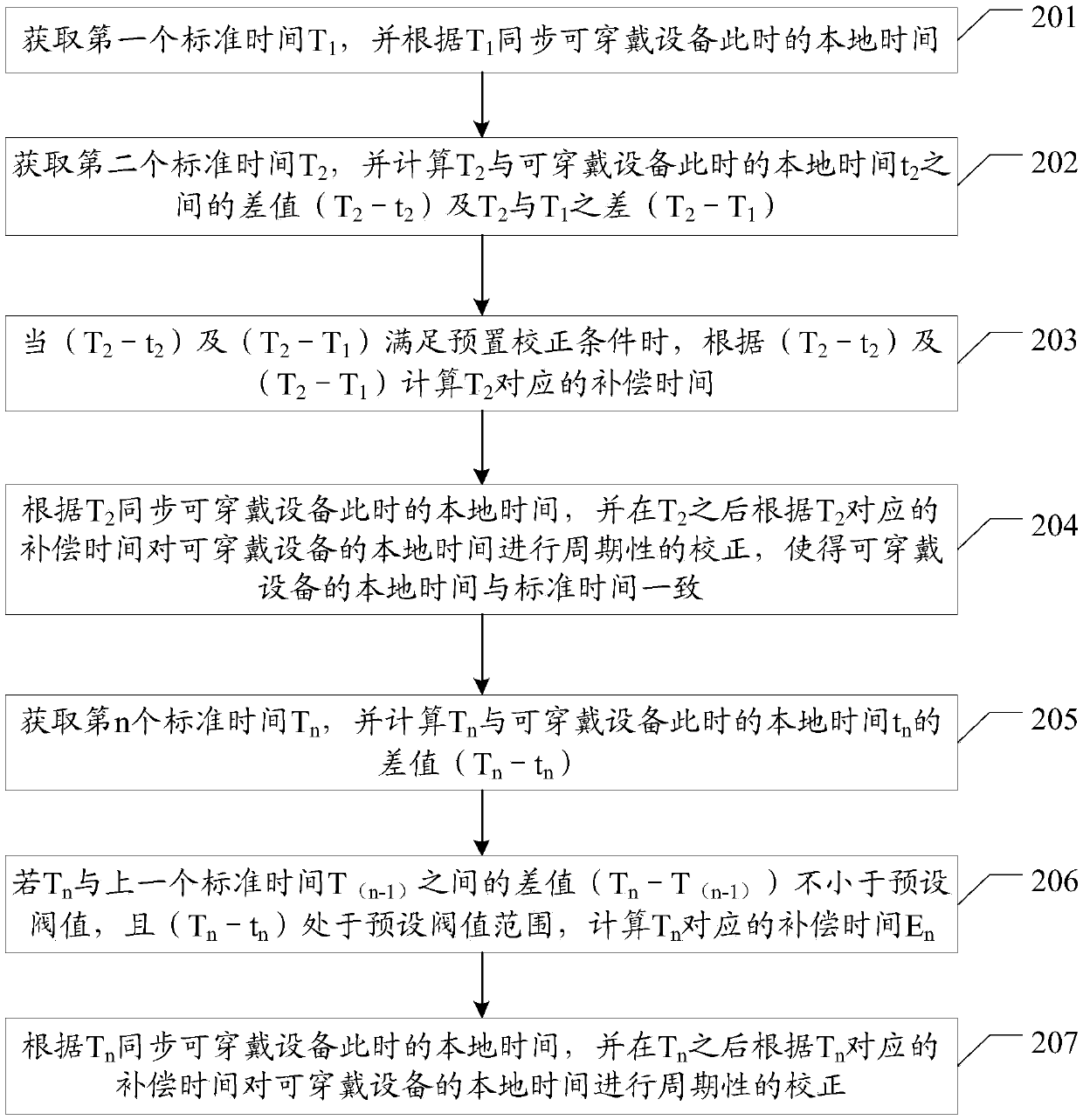

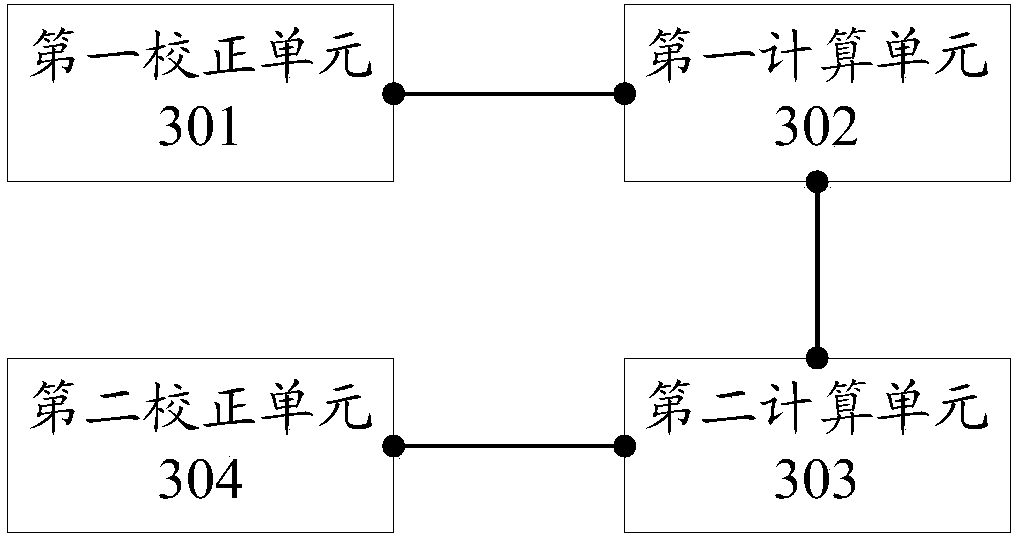

Wearable device time calibration method and wearable device

InactiveCN107894703ACalibration automaticAutomatic correctionSynchronous motors for clocksTransmissionStandard timeReal-time computing

Embodiments of the invention provide a wearable device time calibration method and a wearable device to implement automatic correction of a local time of a wearable device. The method according to theembodiment of the invention includes the steps of acquiring a first standard time T1, and synchronizing a local time of the wearable device at the moment according to the T1; acquiring a second standard time T2, and calculating a difference (T2-t2) between the T2 and a local time t2 of the wearable device at the moment and a difference (T2-T1) between T2 and T1; when the (T2-t2) and the (T2-T1) satisfy a preset correction condition, calculating the compensation time corresponding to the T2 according to the (T2-t2) and the (T2-T1); and synchronizing the local time of the wearable device at themoment according to the T2, and after the T2, periodically correcting the local time of the wearable device according to the compensation time corresponding to the T2, so that the local time of the wearable device is consistent with the standard time.

Owner:GUANGDONG TRANSTEK MEDICAL ELECTRONICS CO LTD

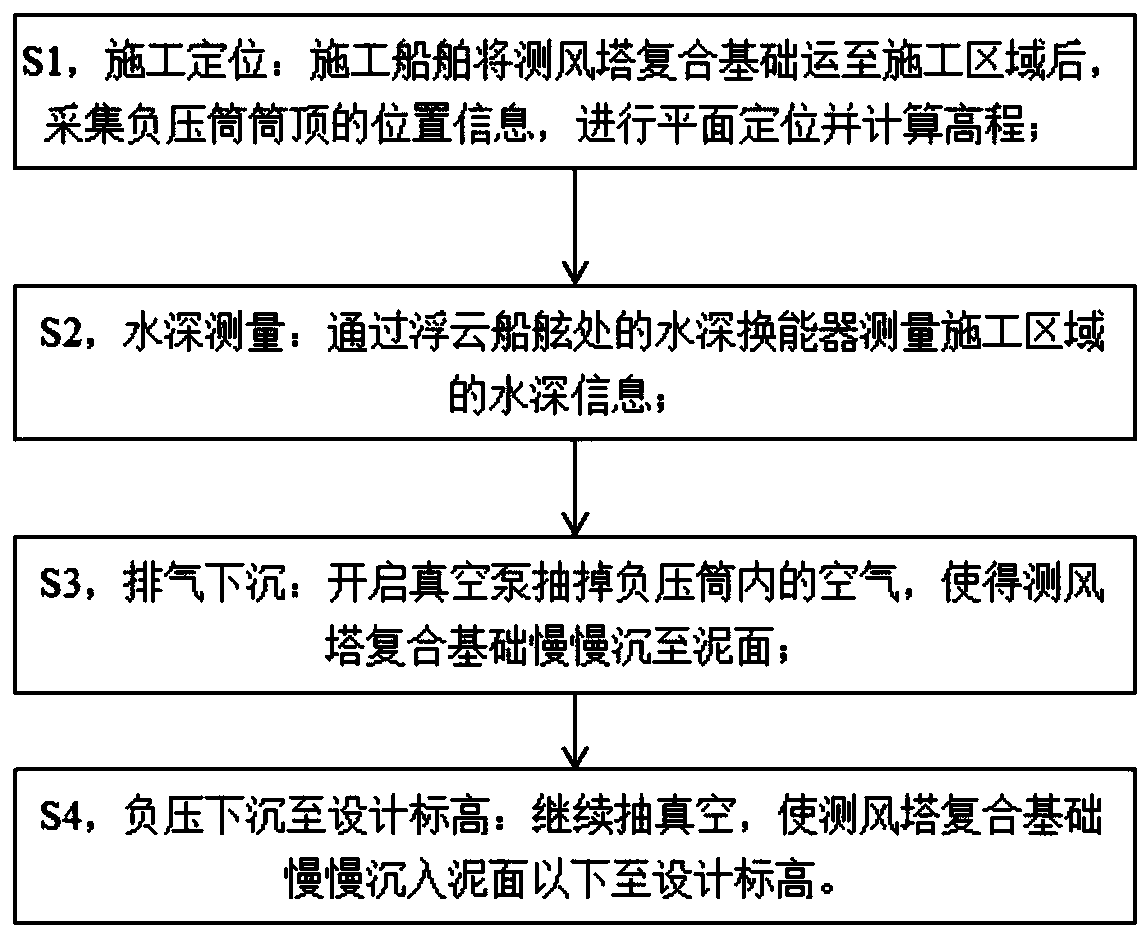

Automatic negative-pressure sinking method for jacket multi-tube negative-pressure tube anemometer tower composite foundation

InactiveCN109653229AImprove efficiency, frequencyFast reading speedHeight/levelling measurementCaissonsAutomatic controlEnergy converter

The invention discloses an automatic negative-pressure sinking method for a jacket multi-tube negative-pressure tube anemometer tower composite foundation. The method includes the steps: S1 construction positioning: acquiring position information of the top of a negative-pressure tube, positioning a plane and calculating elevation after conveying the anemometer tower composite foundation to a construction area by a construction ship; S2 water depth measurement: measuring the water depth of the construction area by a water depth energy converter at a floating cloud ship board; S3 exhaust sinking: starting a vacuum pump to pulling out air in the negative-pressure tube and enabling the anemometer tower composite foundation to slowly sink to a sludge surface; S4 negative-pressure sinking to the designed elevation: continuing vacuum pumping and enabling the anemometer tower composite foundation to slowly sink into the sludge surface and reach the designed elevation. Compared with the priorart, the method realizes automatic negative-pressure sinking of the anemometer tower composite foundation by combining automatic control with an automatic leveling technology and has the advantages ofhigh automation degree, strong reliability and the like.

Owner:CCCC SHANGHAI THIRD HARBOR SCI RES INST CO LTD +1

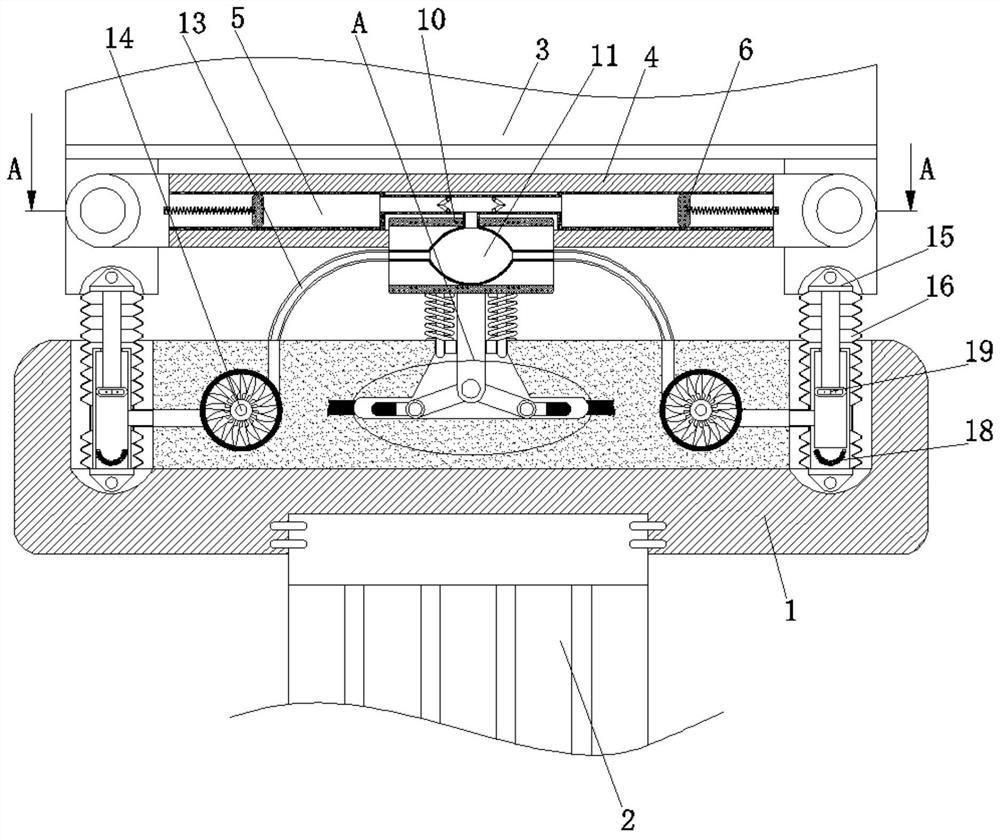

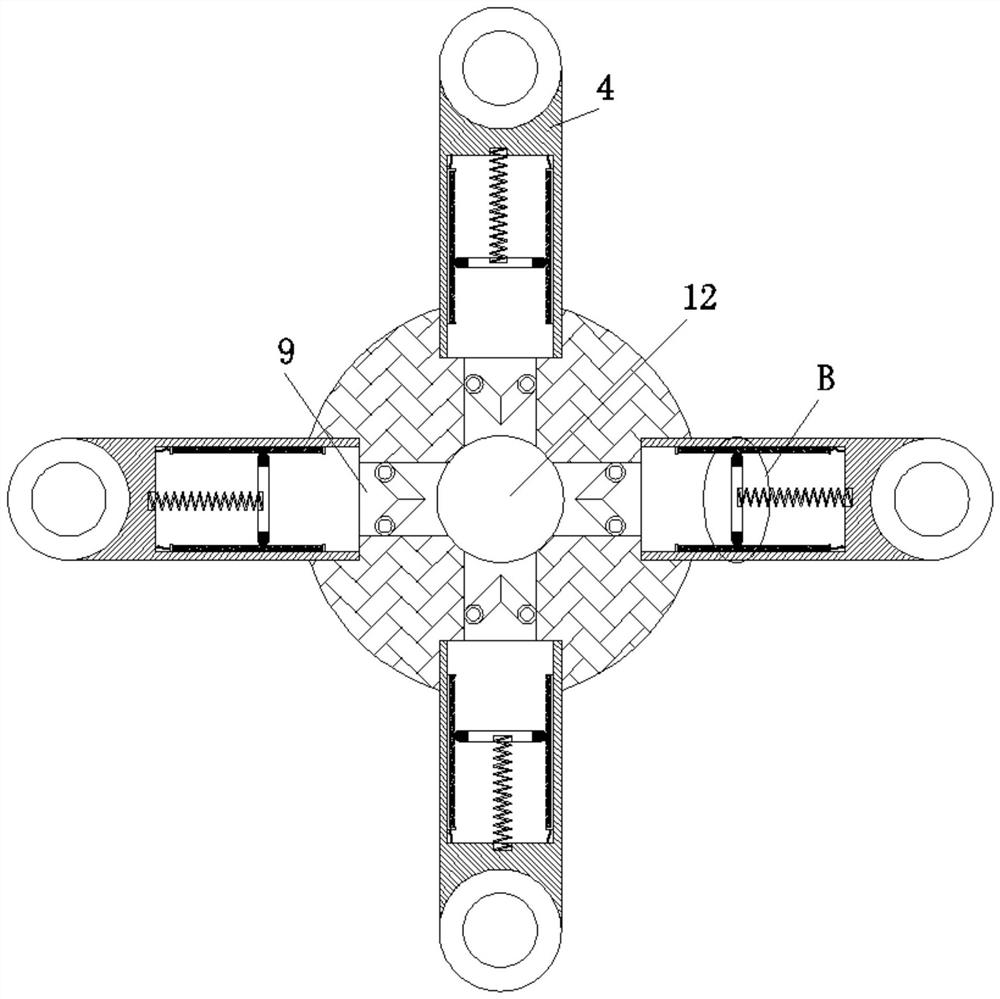

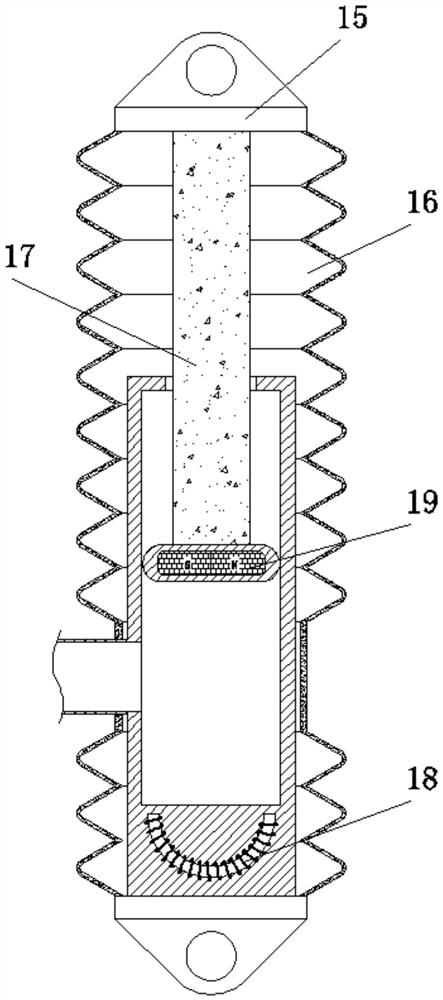

Grinding machine base capable of avoiding transverse inertia deviation and achieving intelligent balance

InactiveCN112621562AAvoid Lateral Inertial OffsetFilter mechanical shockGrinding carriagesNon-rotating vibration suppressionMetal stripsVibration amplitude

The invention relates to the technical field of hardware machinery, and discloses a grinding machine base capable of avoiding transverse inertia deviation and achieving intelligent balance. The grinding machine base capable of avoiding transverse inertia deviation and achieving intelligent balance comprises a rack, wherein a transmission shaft is fixedly connected to the bottom of the rack, a containing plate is movably connected to the upper end of the rack, and a supporting plate is fixedly connected to the lower end of the containing plate; and a sliding groove is formed in the supporting plate, a sliding block is slidably connected into the sliding groove, a metal contact is fixedly connected to the side surface of the sliding block, a resistance strip is slidably connected to the side surface of the metal contact, and an air inlet hole is formed in the bottom of the middle of the supporting plate. A machined workpiece is fixedly connected to the upper end of the containing plate, an installation frame is pressed, a metal feeler lever is connected with a metal strip, an air pump in an air duct starts to work, an elastic cavity and a spring air bag are inflated, and therefore the effects of filtering mechanical vibration generated during workpiece machining, and preventing the influence of the vibration amplitude on the surface precision of the workpiece are achieved.

Owner:杭州锐霓机械科技有限公司

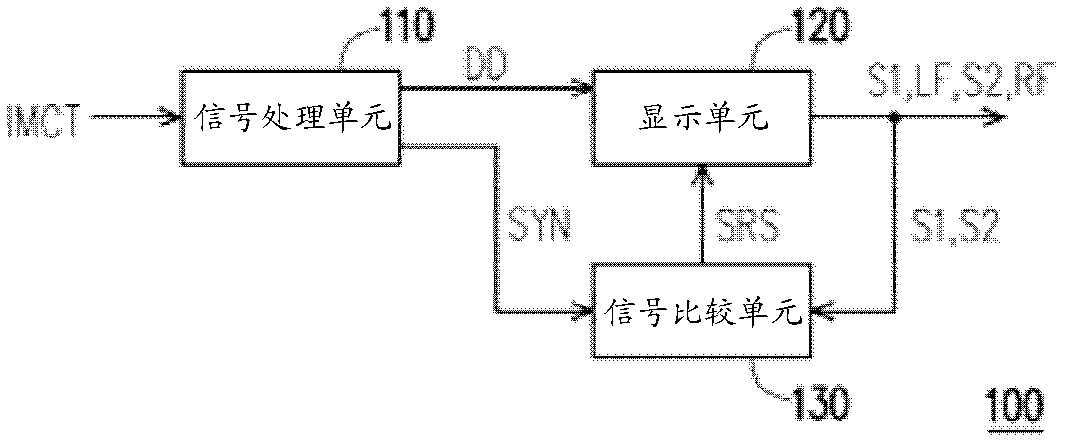

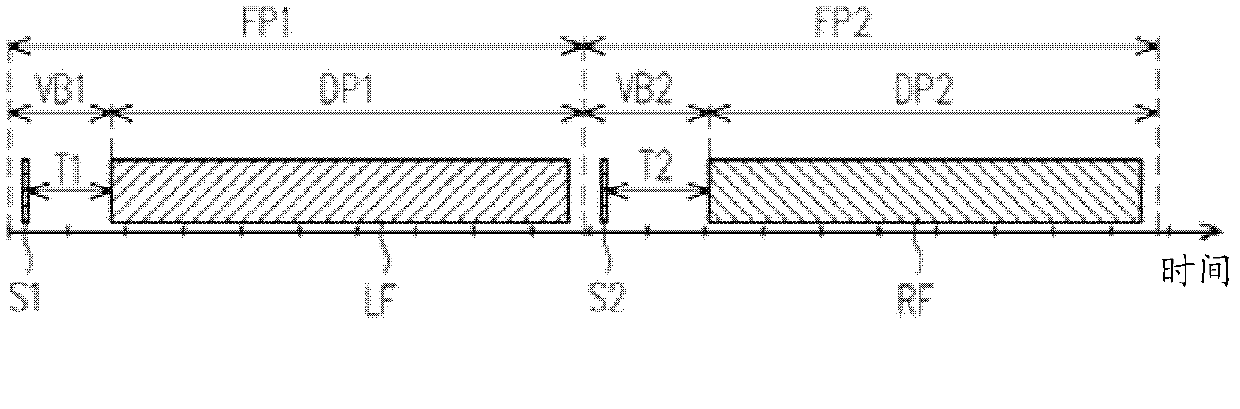

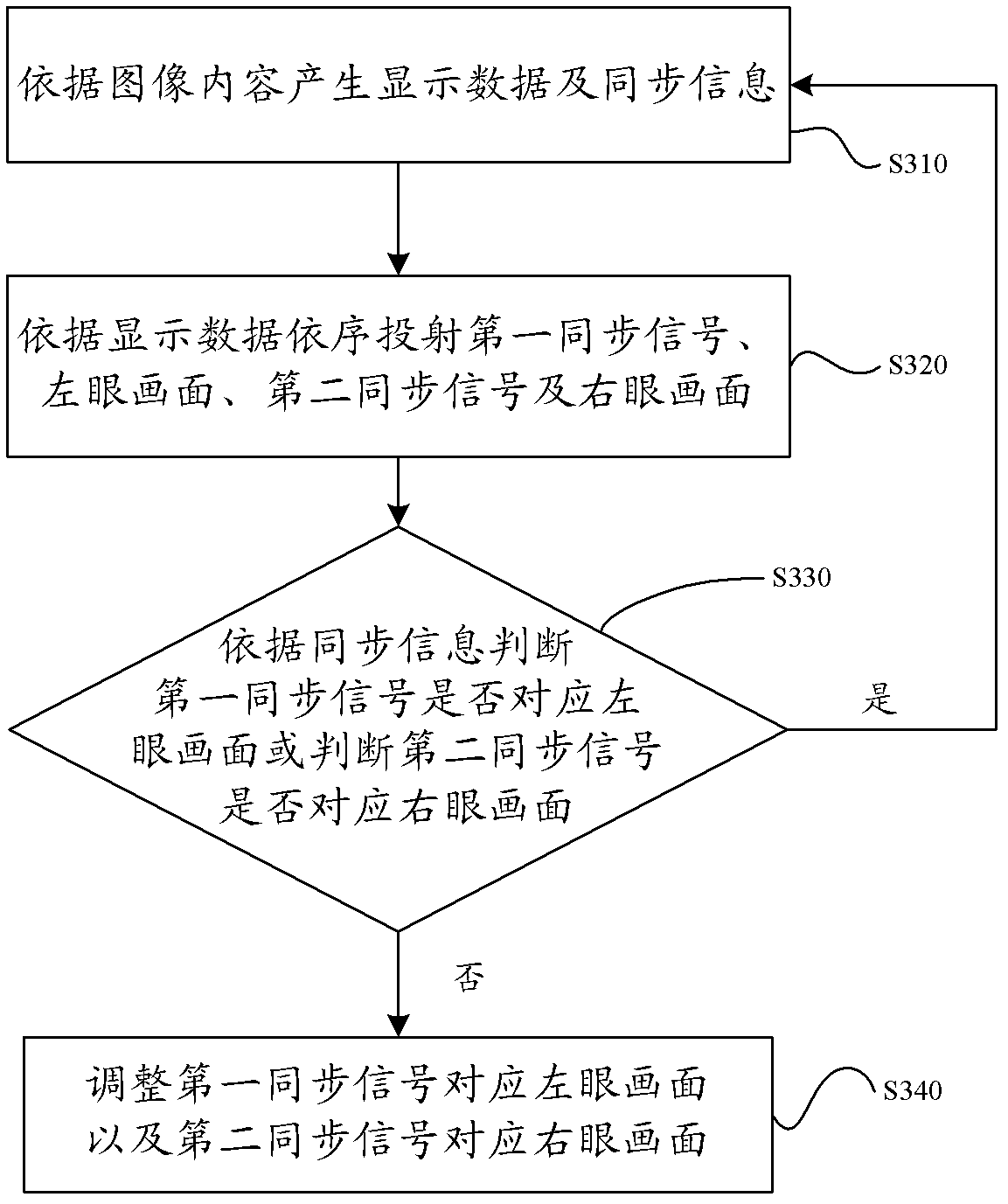

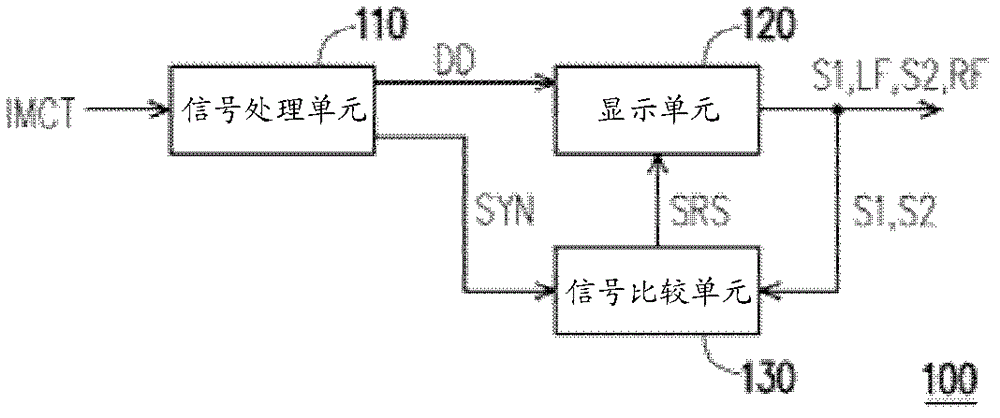

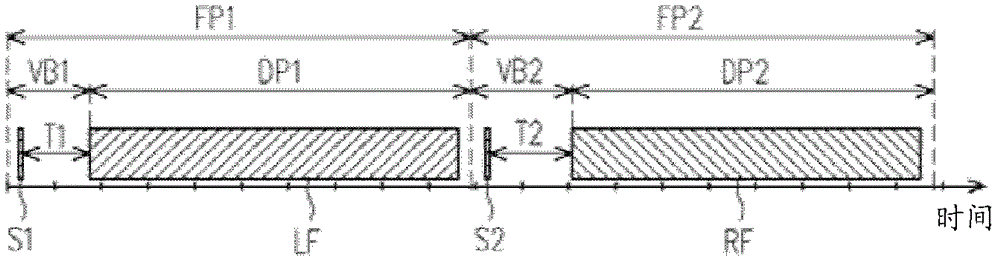

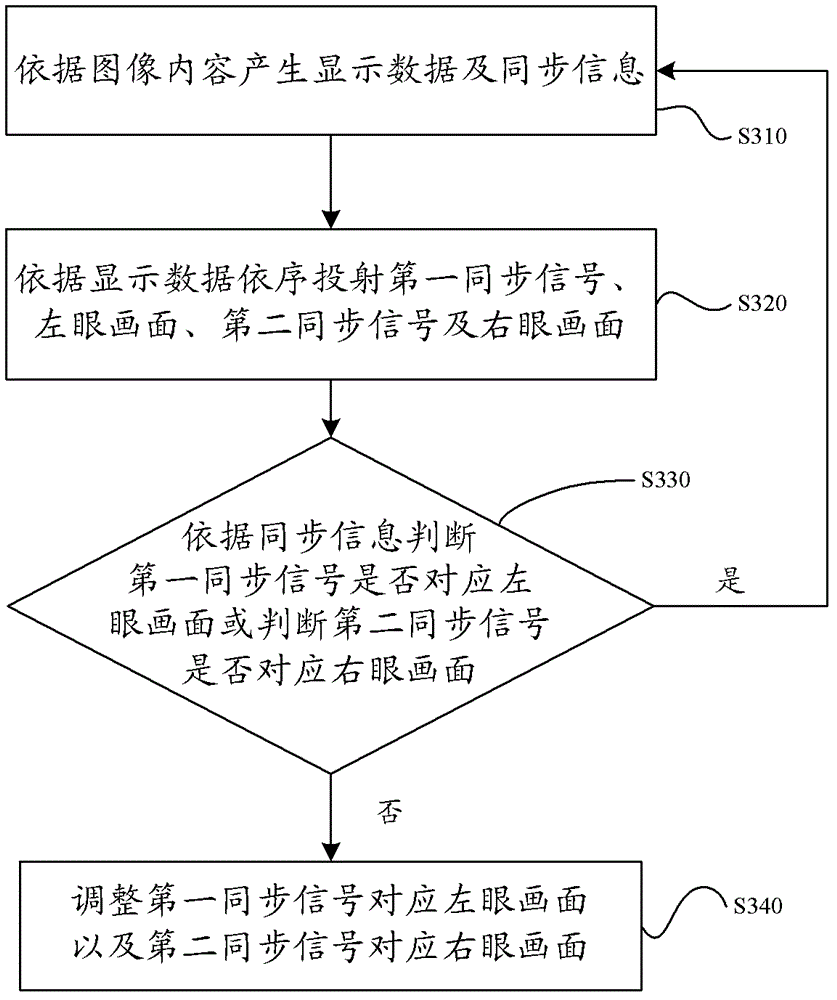

Digital optical processor projector and displaying method thereof

The invention provides a digital optical processor projector and a displaying method of the digital optical processor projector. The digital optical processor projector comprises a signal processing unit, a displaying unit and a signal comparing unit. The signal processing unit generates displaying data and synchronous information according to the content of images. The displaying unit sequentially projects a first synchronous signal, the image of the left eye, a second synchronous signal and the image of right eye according to the displaying data. The signal comparing unit judges whether the first synchronous signal corresponds to the image of the left eye or judges whether the second synchronous signal corresponds to the image of the right eye according to the synchronous information. When the first synchronous signal does not correspond to the image of the left eye or the second synchronous signal does not correspond to the image of the right eye, the signal comparing unit outputs a synchronous correction signal to the displaying unit to adjust the first synchronous signal and enable the first synchronous signal to correspond to the image of the first eye or adjust the second synchronous signal and enable the second synchronous signal to correspond to the image of the right eye.

Owner:ACER INC

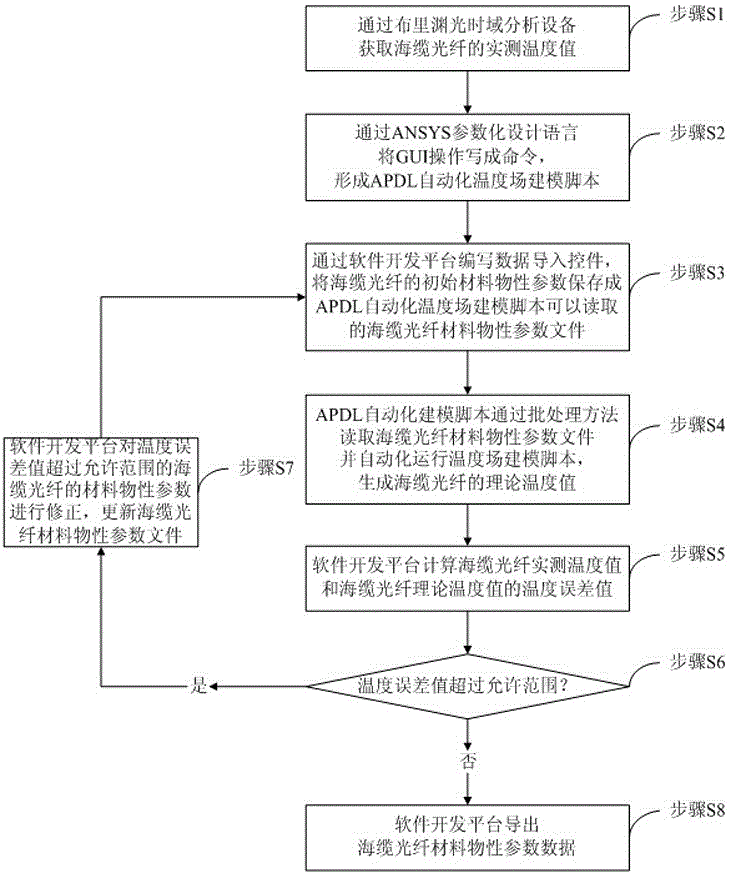

Method for automatically correcting physical property parameter of photoelectric composite submarine cable material

ActiveCN105046002AShorten modeling operation cycleReduce staffingSpecial data processing applicationsSoftware developmentEngineering

A method for automatically correcting a physical property parameter of a photoelectric composite submarine cable material comprises: reading a physical property parameter file of a submarine cable optical fiber and automatically running the file by using an APDL (ANSYS Parametric Design Language) automated temperature field modeling script which is formed by an ANSYS parameterization design language; generating a theoretical temperature value of the submarine cable optical fiber; by a software development platform, calculating a temperature error value between an actually measured temperature value of the submarine cable optical fiber and the theoretical temperature value of the submarine cable optical fiber; by the software development platform, performing correction on the material physical property parameter of the submarine cable optical fiber with the temperature error value exceeding an allowed range, and updating the physical property parameter file of the submarine cable optical fiber by using the corrected material physical property parameter; and performing iteration to obtain a material physical property parameter that can enable the temperature error value between the actually measured temperature value of the submarine cable optical fiber and the theoretical temperature value of the submarine cable optical fiber to be within the allowed range. The method is efficient, simple, automatic, fast and convenient, and can greatly shorten the molding operation period, reduce personnel assignment needed for parameter correction and achieve double effects of efficient modeling and accurate establishment of a conductor temperature database.

Owner:SHANGHAI MARITIME UNIVERSITY

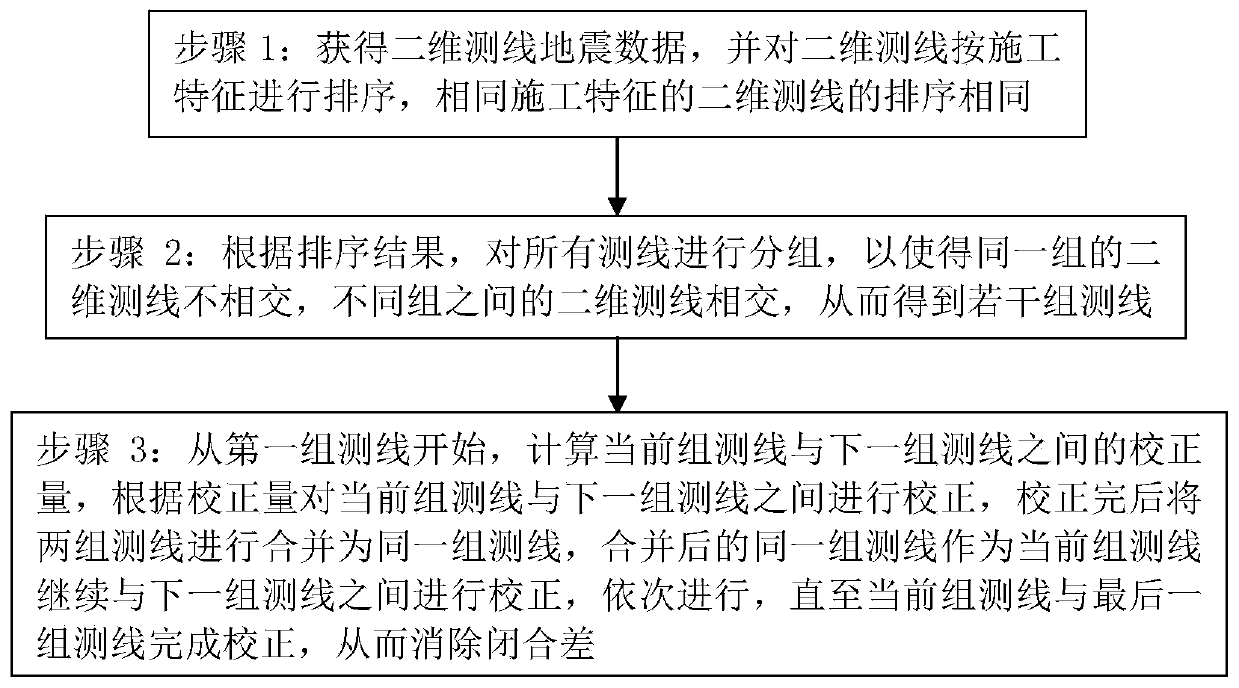

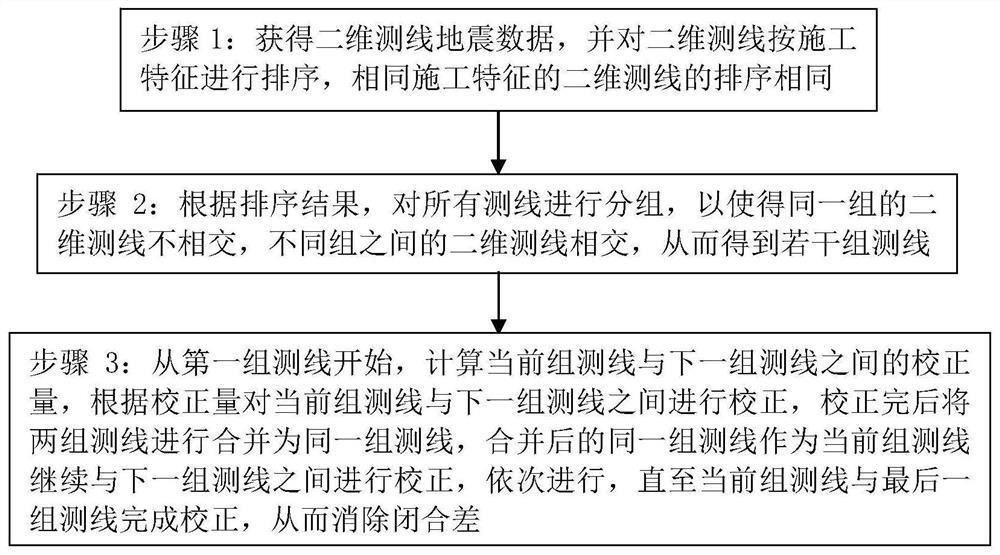

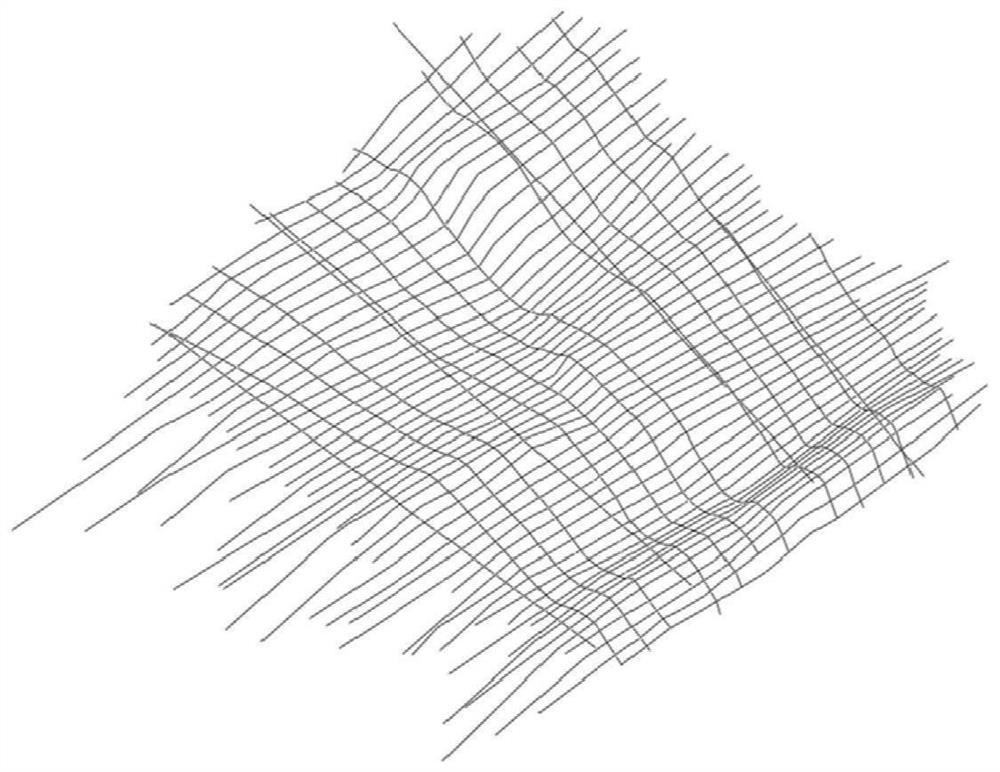

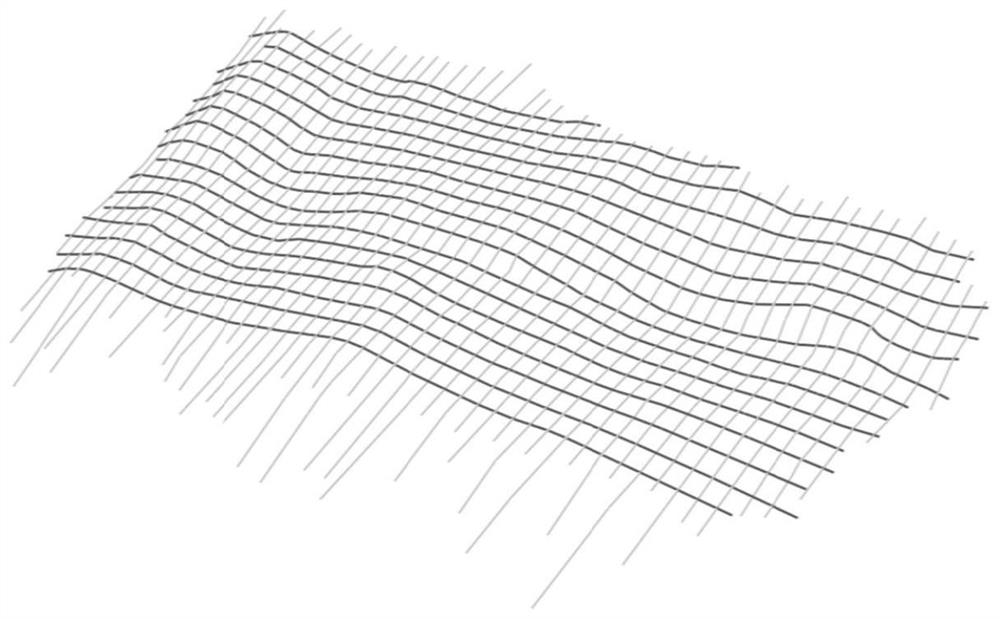

Two-dimensional survey line seismic data closure error correction method and processing terminal

The invention relates to a two-dimensional survey line seismic data closure error correction method and a processing terminal. The two-dimensional survey line seismic data closure error correction method comprises the steps of: step 1, acquiring two-dimensional survey line seismic data, sorting two-dimensional survey lines according to construction features, and enabling the two-dimensional surveylines with the same construction features to be the same in sorting; step 2, grouping all the survey lines according to a sorting result, so that the two-dimensional survey lines in the same group are not intersected, the two-dimensional survey lines in different groups are intersected, and a plurality of groups of survey lines are obtained; and step 3, calculating a correcting value between thecurrent group of survey lines and the next group of survey lines, performing correction between the current group of survey lines and the next group of survey lines according to the correcting value,combining the two groups of survey lines into the same group of survey lines after correction is completed, taking the combined group of survey lines as the current group of survey lines, continuing to perform correction between the current group of survey lines and the next group of survey lines, and sequentially performing correction to complete correction. The two-dimensional survey line seismic data closure error correction method is high in efficiency and precision of eliminating the closure error, can achieve the low-cost automatic correction, and is especially suitable for the closure error correction of mass seismic data.

Owner:GUANGZHOU MARINE GEOLOGICAL SURVEY

Component for a machine tool, machine tool and method for identifying wear

PendingCN112203836AImprove processing qualityIncrease flexibilityShaping safety devicesBrake typesMachine toolIndustrial engineering

Owner:BYSTRONIC LASER

A correction method and processing terminal for two-dimensional survey line seismic data closure error

The present invention relates to a correction method and a processing terminal for two-dimensional survey line seismic data closure difference. The method includes the following steps: Step 1: Obtain two-dimensional survey line seismic data, and sort the two-dimensional survey lines according to construction characteristics, The sorting of 2D survey lines with the same construction features is the same; Step 2: According to the sorting results, group all survey lines so that the 2D survey lines of the same group do not intersect, and the 2D survey lines of different groups intersect, so that Obtain several groups of survey lines; Step 3: Calculate the correction amount between the current group of survey lines and the next group of survey lines, and perform corrections between the current group of survey lines and the next group of survey lines according to the correction amount. Groups of measuring lines are merged into the same group of measuring lines, and as the current group of measuring lines, continue to be calibrated with the next group of measuring lines, and the calibration is completed in sequence. The invention has high efficiency and precision in eliminating closure error, can automatically correct at low cost, and is especially suitable for correction of closure error of a large amount of seismic data.

Owner:GUANGZHOU MARINE GEOLOGICAL SURVEY

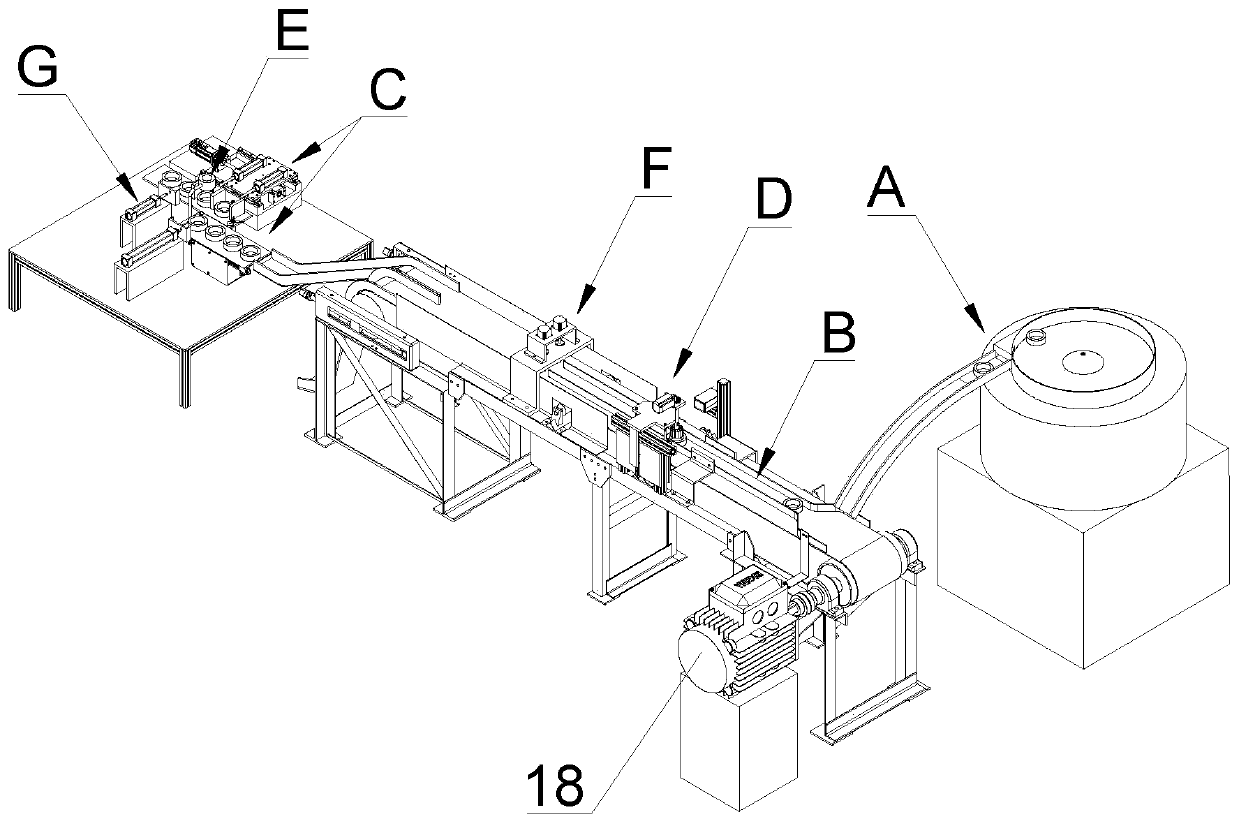

a filling machine

The invention discloses a filling machine. The filling machine comprises a conveying mechanism. The conveying mechanism comprises a rack, a bottle tidying disc rotationally connected to the rack, anda first drive mechanism driving the bottle tidying disc to rotate. The bottle tidying disc is provided with a stirring arm forcing penicillin bottles to move to the outer circle of the bottle tidyingdisc, a fence surrounding the bottle tidying disc in the circumferential direction, and an inner fence fixed to the inner side of the fence. The fence is fixed to the rack, a channel for outputting the penicillin bottles is formed by the inner fence and the fence, a guide groove is formed in one side of the channel, and an opening of the part, on the downstream part of the guide groove, of the channel is provided with an upper guide rail matched with the necks of the penicillin bottles. An impeller for conveying the penicillin bottles one by one is arranged at the tail end of the channel. Continuity, consistency and vacancy avoiding of penicillin bottle conveying are guaranteed, and good filling conditions are provided for subsequent mechanisms.

Owner:ZHEJIANG FENGAN BIOPHARM

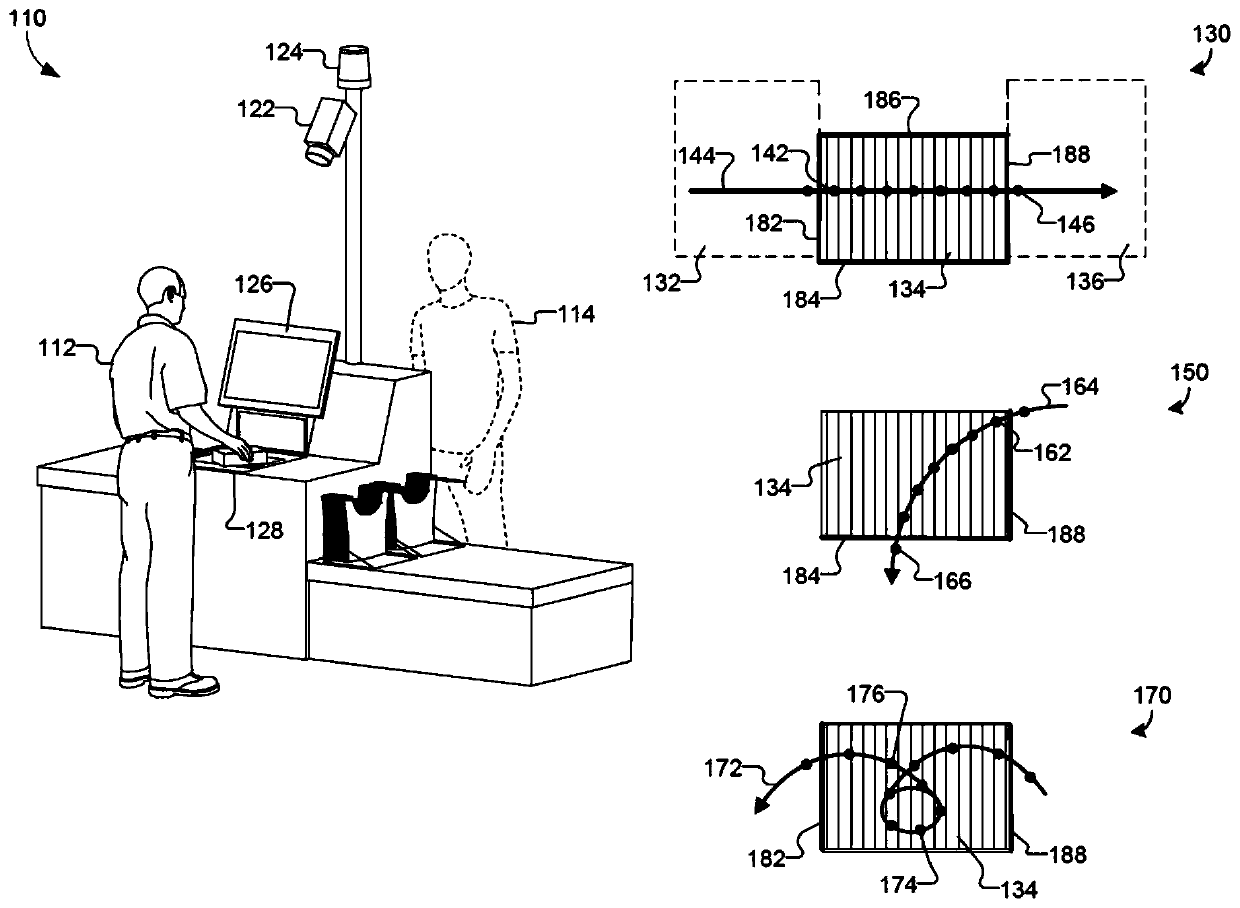

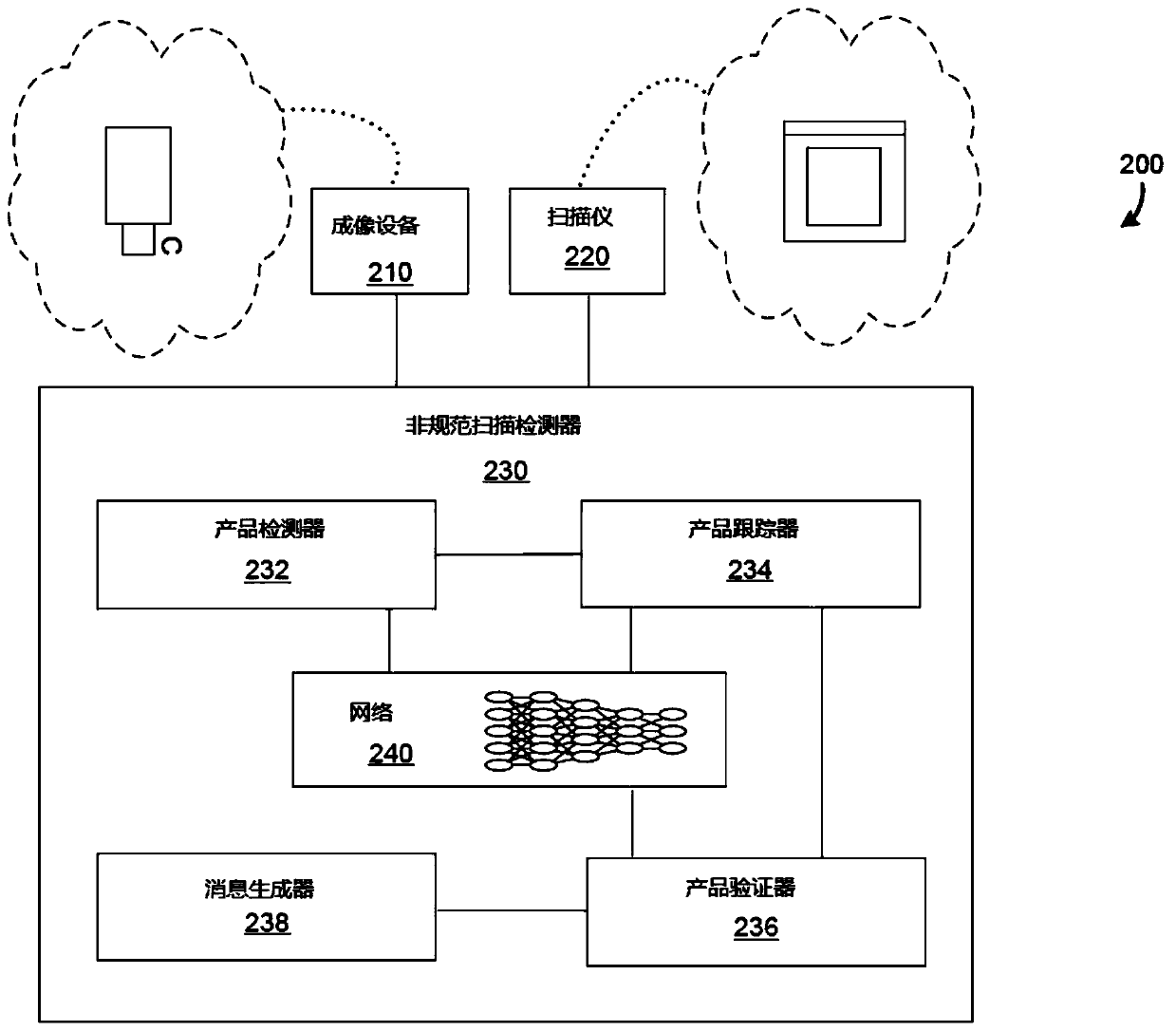

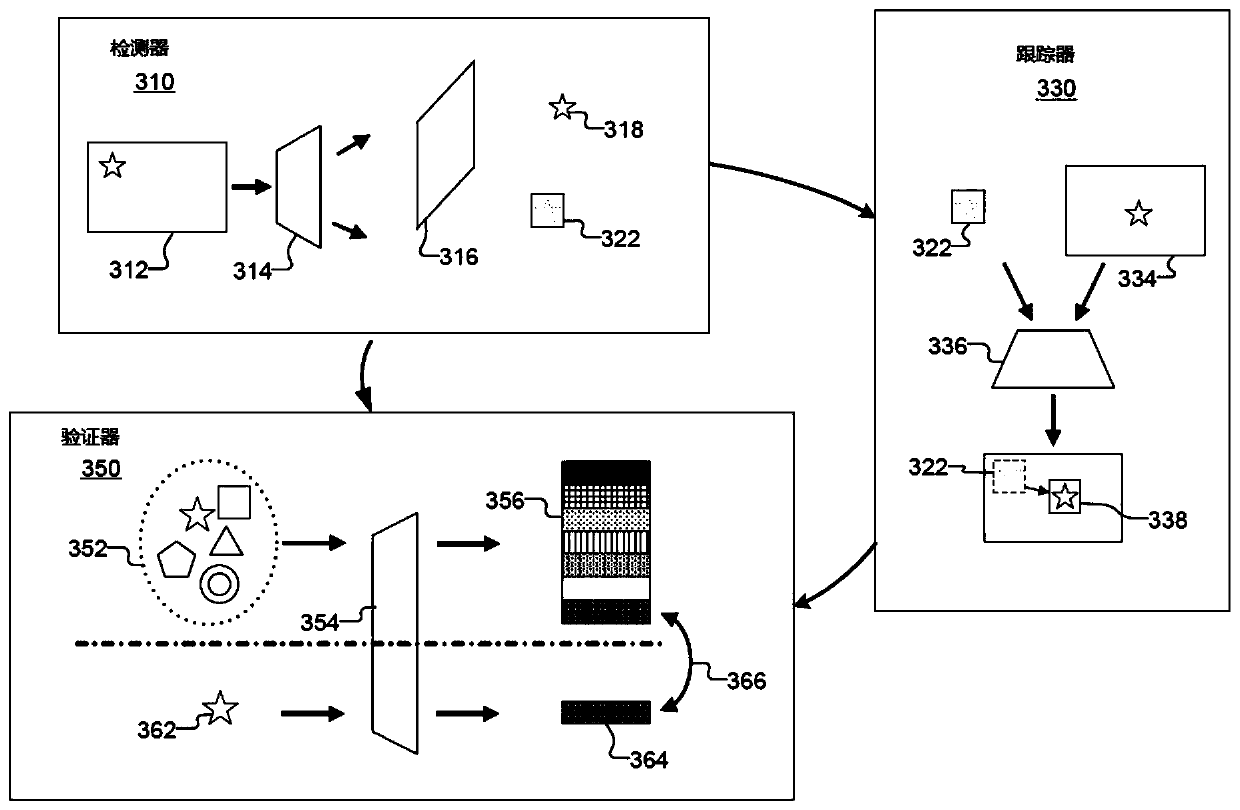

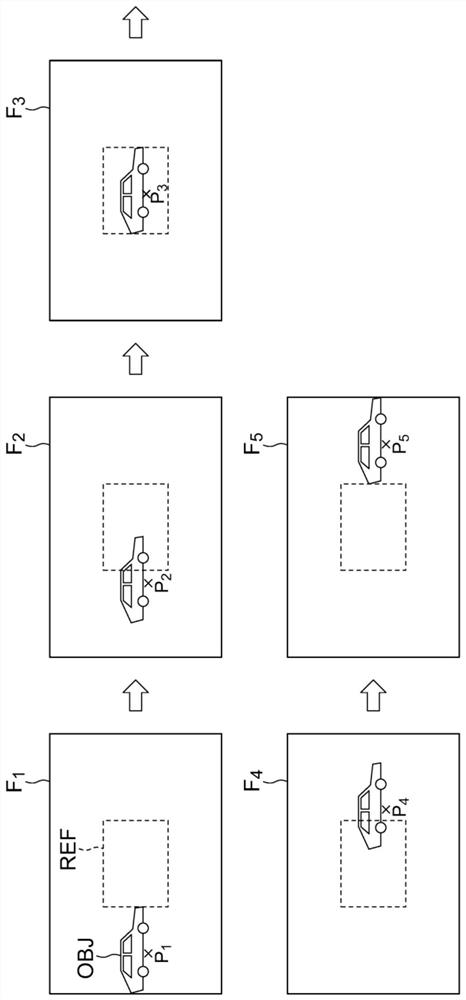

Non-standard scanning for retail system

PendingCN110998592AImproved detection of non-standard scansEffective trackingImage enhancementImage analysisComputer visionOperations research

Aspects of the present application include techniques for detecting non-canonical scans, particularly when a retail system fails to collect real information of a product. The disclosed retail system retrieves an image covering a particular area, such as an image of a specified scan area. Also, the disclosed retail system detects the product from these images using a neural network and tracks the movement trajectory of the product in the particular region. A non-canonical scan may be detected when a tracked product in the image does not match a product collected by a scanner of the retail system.

Owner:SHANGHAI YUEPU INVESTMENT CENT (LLP)

A steel pipe automatic correction robot

The invention discloses a steel pipe automatic correction robot which comprises an annular main rack, a rotating rack, a rotating bearing, a large gear and a small gear, wherein six roller mounting racks are respectively and slidingly mounted on six mounting shafts; six rollers are respectively and rotationally mounted on the six roller mounting racks; two roller motors are respectively mounted on a roller mounting rack at the lower part of and a roller mounting rack at the upper part of the annular main rack; a rotating motor mounting rack is mounted at the external periphery of the annular main rack; a rotating motor is mounted on the rotating motor mounting rack; the rotating bearing is coaxially mounted at the lower part of the annular main rack; the large gear is coaxially mounted on the rotating bearing; cylinder bodies of two hydraulic cylinders are respectively mounted on two hydraulic cylinder mounting racks; piston rods of the two hydraulic cylinders respectively stretch into the rotating rack; and pressing head jacking blocks are mounted at the end parts of the piston rods. Through the arrangement of the automatic rollers and the rotating rack, the purpose of correcting a steel pipe efficiently and automatically is realized. The steel pipe automatic correction robot is simple in structure, low in cost and convenient to operate.

Owner:常熟市创福管业有限公司

Film blowing machine capable of being adjusted according to specific production conditions and method

The invention relates to the technical field of film blowing, and discloses a film blowing machine capable of being adjusted according to the specific production situation and a method. The film blowing machine comprises a shell, a trigger mechanism is movably connected in the shell, an air cavity is formed in the right end of the trigger mechanism and located in the shell, an air outlet hole is formed in the upper end of the air cavity and located in the upper end of the shell, a driving rod is movably connected to the interior of the shell, a transmission mechanism is fixedly connected to the bottom of the driving rod, and an adjusting mechanism is movably connected to the bottom of the transmission mechanism. A bearing plate drives a pressure adjusting block to move towards the bottom of the shell, so that the distance between the pressure adjusting block and a flow guide block is shortened, extrusion force is applied to the interior of the flow guide block, the pressure intensity in the flow guide block is enhanced in a short time, the flow speed in the flow guide block is increased, the thickness of a film at the upper end of the flow guide block is increased, and therefore, an effect of automatically correcting the film is achieved when the thickness of the film is not uniform due to equipment.

Owner:许儒连

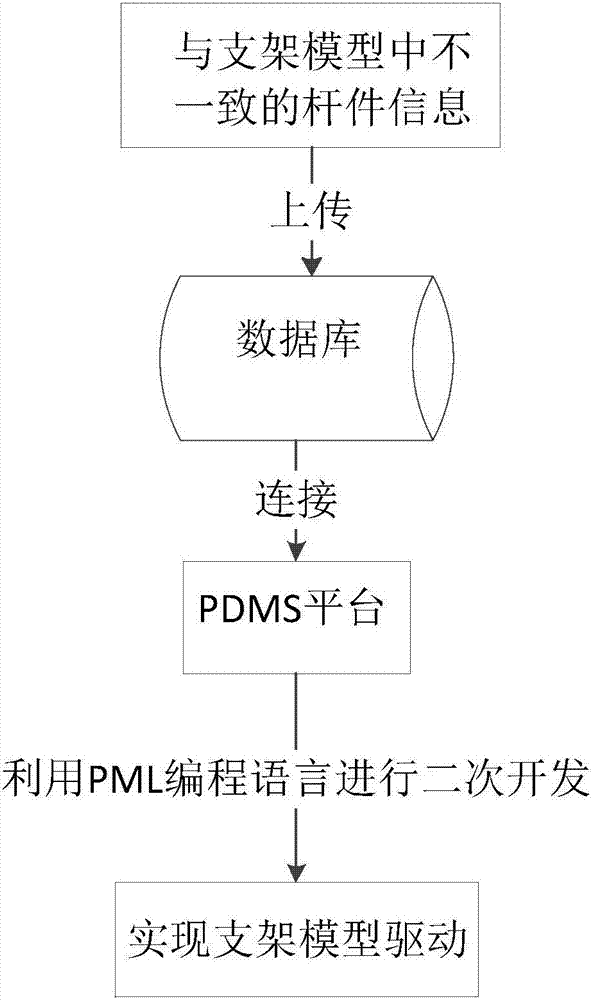

Large complex bracket model correction method

ActiveCN106897498AAutomatic correctionAccurate correctionGeometric CADDesign optimisation/simulationPerformance functionModel modification

The invention discloses a large complex bracket model correction method. The method comprises the following steps of (1) performing modeling on a large complex bracket in PDMS software, then generating a large complex bracket processing drawing, and performing processing construction on the large complex bracket according to the drawing, wherein each rod piece of a model formed by modeling adopts an integral rod piece; (2) establishing a correction database of the large complex bracket model in an SQL database; (3) performing secondary development on the PDMS software by utilizing a PML programming language to realize information interaction between the PDMS software and the correction database; and (4) adding a performance function of weld seams for the rod pieces of the model in the PDMS software to drive the model by utilizing the PML programming language, thereby realizing a function of automatically adding the weld seams for the large complex bracket model, and performing position addition of the weld seams. The method has the beneficial effects that the large complex bracket model can be automatically and accurately corrected, so that the model modification efficiency is improved.

Owner:天津博迈科海洋工程有限公司

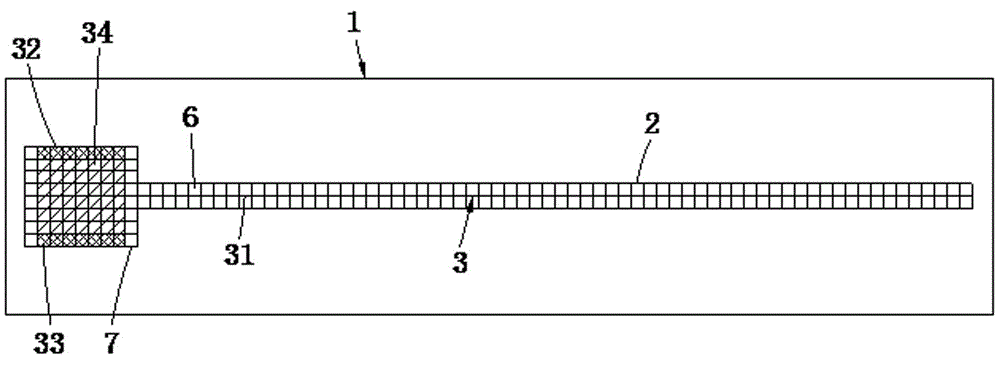

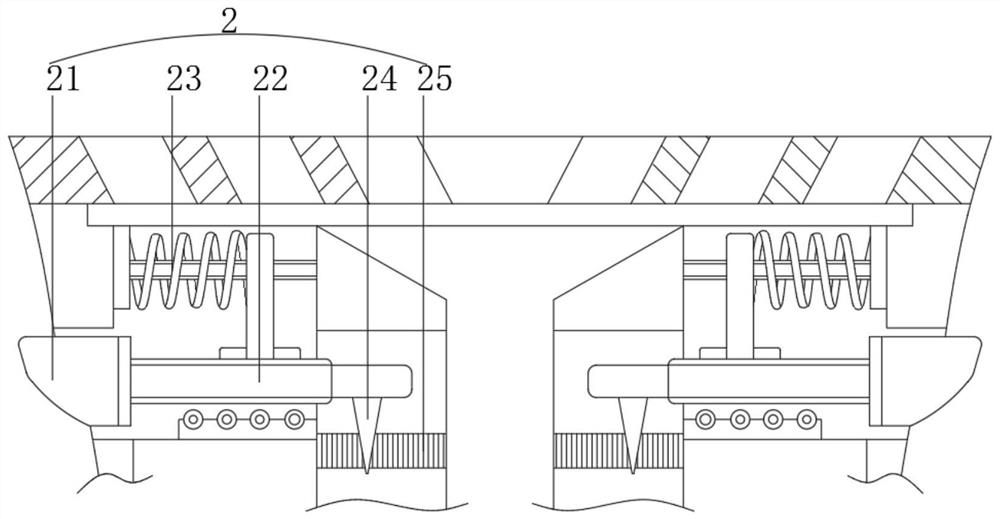

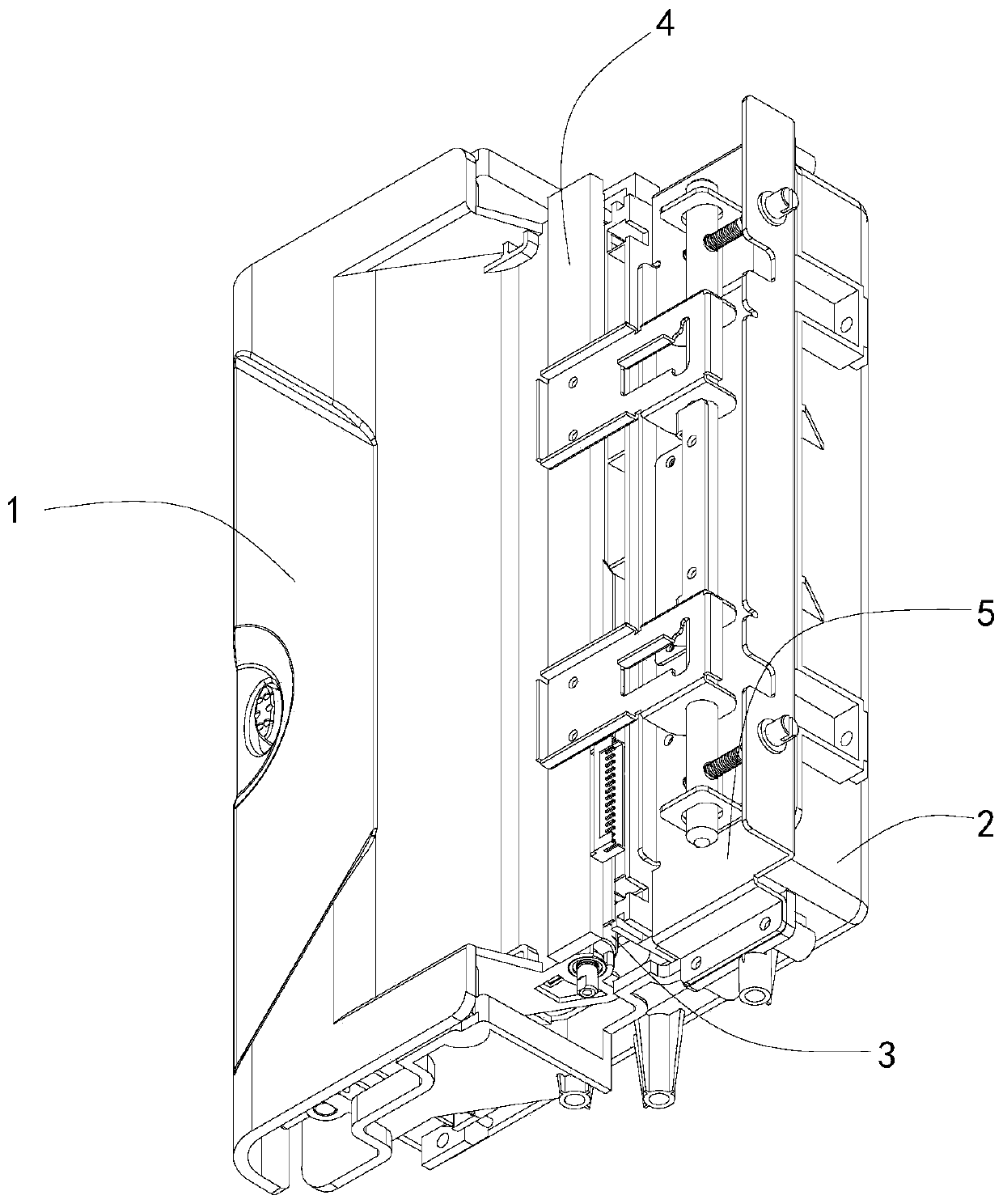

Automatic correcting device for filter resistor frame

InactiveCN108296760AEasy to installEasy to fixMetal working apparatusUltimate tensile strengthResistor

The invention discloses an automatic correcting device for a filter resistor frame. The automatic correcting device comprises a rectangular underframe, a transverse supporting rod is arranged in the middle of the rectangular underframe, and automatic correcting assemblies fixedly connected with the rectangular underframe are symmetrically arranged on the two sides of the transverse supporting rod.The positions of a transverse assembly and two horizontal assemblies in the transversal and horizontal directions are adjusted, then the filter resistor frame is fixed to the automatic correcting device through a second clamping groove matched with the filter resistor frame, thus the automatic correcting device is used for meeting precise assembling of the filter resistor frame in the assemblingprocess, and the problem of rework caused by the deviation occurring during production is avoided; and according to the automatic correcting device, automatic correcting can be realized, so that the situations of improving of the labor intensity due to back and forth adjusting of the size by workers, and errors caused by human eyes are avoided.

Owner:岳池县宇虹科技有限公司

ECG printing components

ActiveCN109263292BPrevent deviationReduce paper travelOther printing apparatusCardboardHeat sensitive

The invention provides an electrocardiograph printing assembly. According to the electrocardiograph printing assembly, a rubber roller is arranged between the head and tail of a cabin body, and therefore, the paper feeding stroke of two ends of folded thermal sensitive paper can be reduced, and the deviation of the thermal sensitive paper can be avoided; the tail of a front paper guide plate and the head of a rear paper guide are set to be curved surfaces, and therefore, the thermal sensitive paper can be guided to enter a gap between the rubber roller and a thermal printing head, and the deviation of the thermal sensitive paper can be automatically corrected; the head of the front paper guide plate and the tail of the rear paper guide plate are set to be warped surfaces, and therefore, adjacent two pieces of thermal sensitive paper have a larger turning space when being fed, and the deviation of the thermal sensitive paper can be prevented.

Owner:湖南睿健医疗科技有限公司

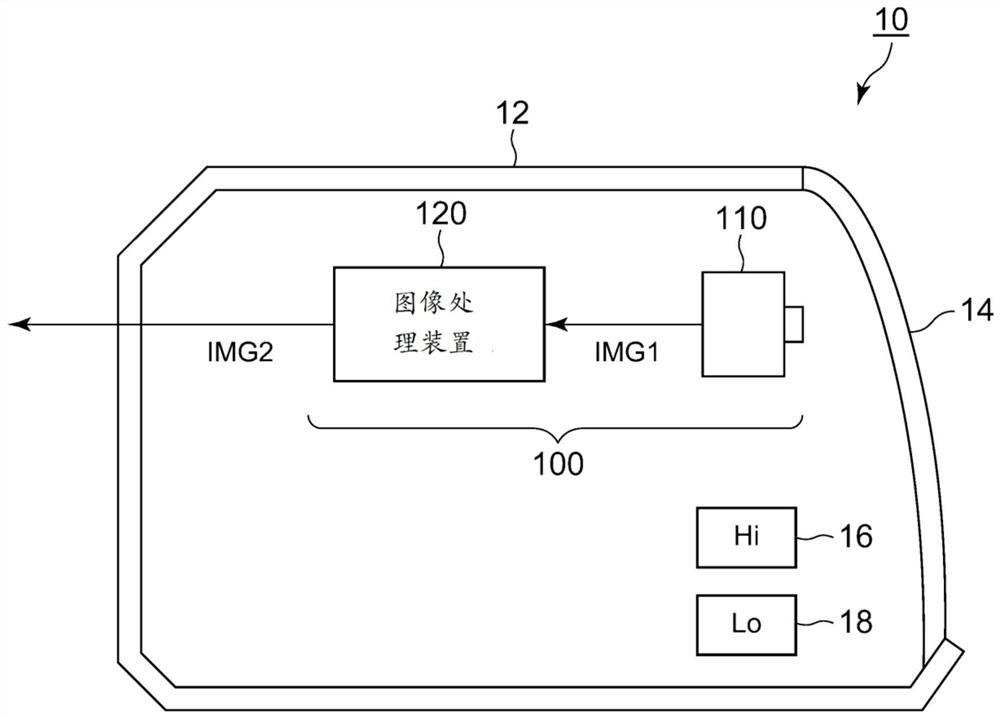

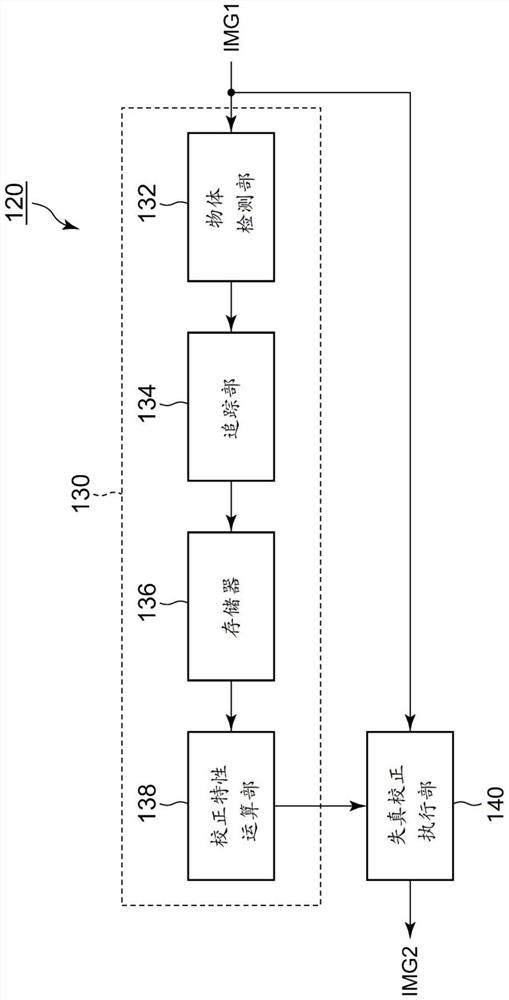

Photographing system and image processing device

ActiveCN113632450AAutomatic correctionReduce the impact of reflectionImage enhancementTelevision system detailsImaging processingComputer graphics (images)

A photographing system (100) comprises a camera (110) and an image processing device (120). The image processing device (120) tracks an object image contained in an output image (IMG1) of the camera (110), and acquires information for correcting distortion of the output image on the basis of variation in shape accompanying the movement of the object. The acquired information is then used to correct the output image.

Owner:KOITO MFG CO LTD

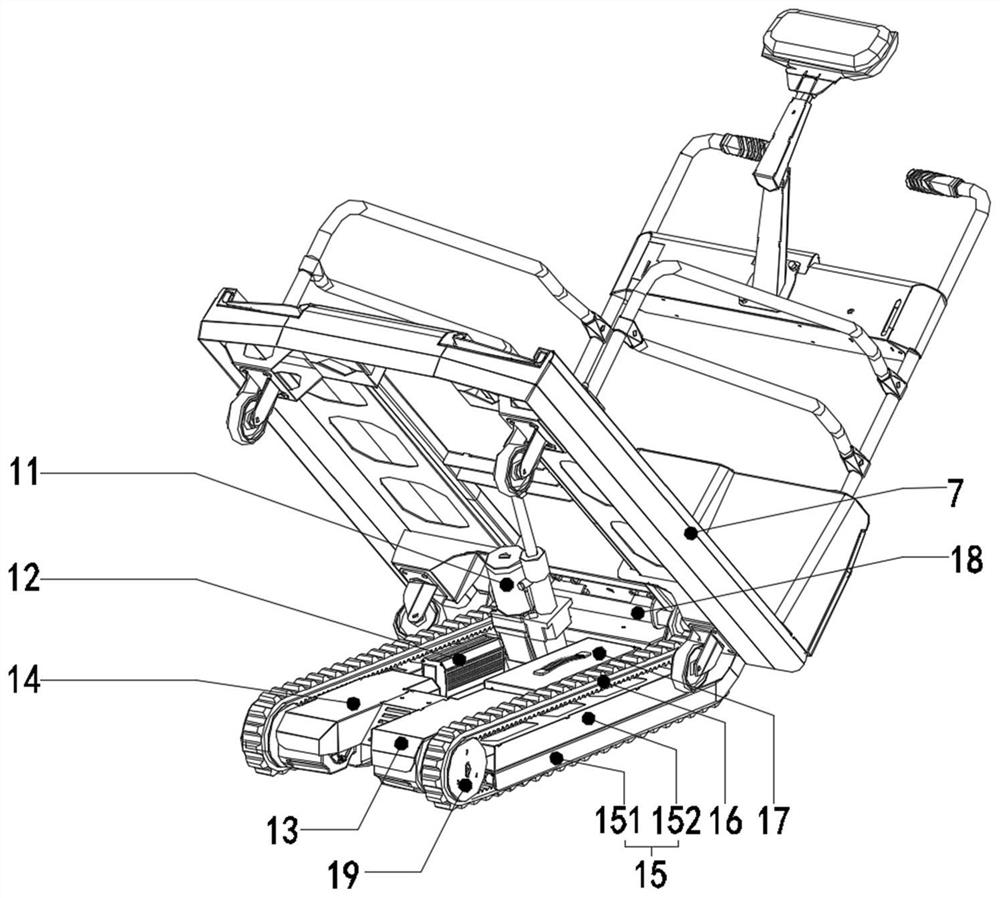

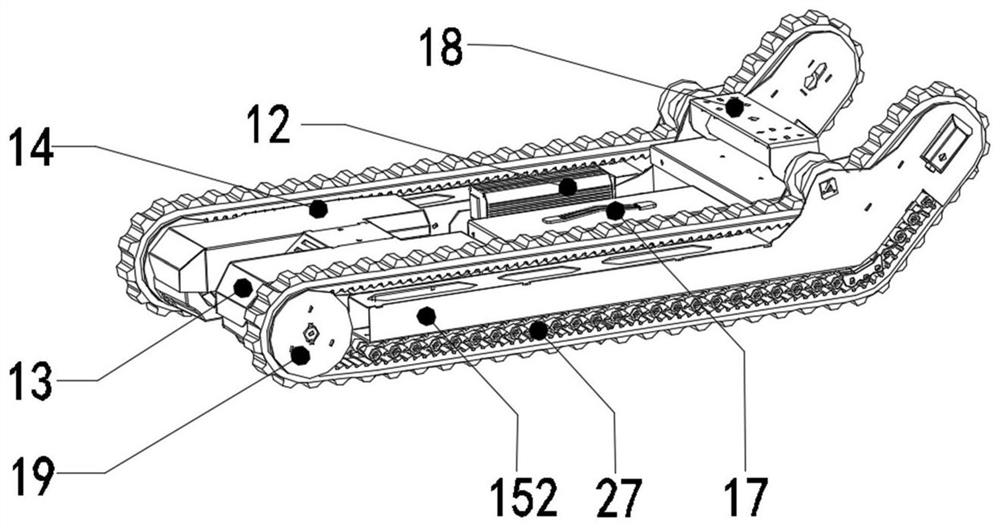

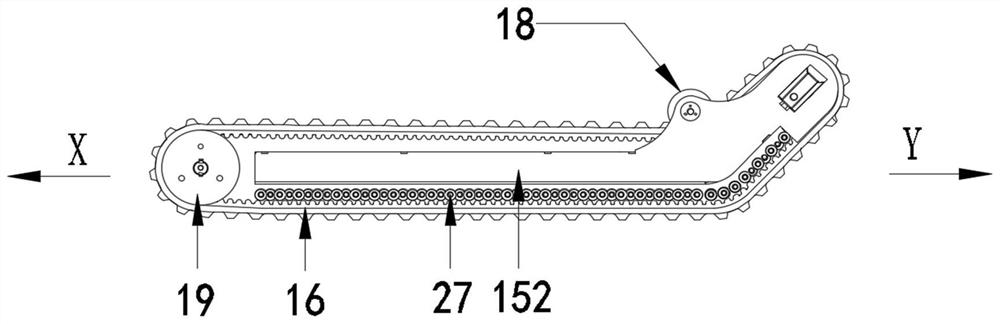

Method and device for climbing stairs with automatic steering adjustment

ActiveCN109229222BAutomatic steering adjustmentRealize steering adjustmentEndless track vehiclesPosition/course control in two dimensionsDriving currentSimulation

Owner:CHENGDU SHANSHEN TRACK TRAFFIC EQUIP CO LTD

Method for testing gear wheels during their production in gear compound cutter

InactiveCN100585323CCenter distance error correctionAutomatic correctionMechanical counters/curvatures measurementsGear-cutting machinesGear wheelEngineering

Owner:LIEBHERR VERZAHNTECHNIK GMBH

Weld joint guide roller for longitudinal welded pipe production line

ActiveCN114799653AEasy to operateEasy to useWelding/cutting auxillary devicesAuxillary welding devicesDrive shaftStructural engineering

The welding seam guide roller comprises a bottom plate, a mounting base and a guide roller body, a first servo motor is fixedly connected to the bottom plate, a transmission shaft is fixedly connected to the output end of the first servo motor, and a rotating disc is fixedly connected to the end, away from the bottom plate, of the transmission shaft; an auxiliary supporting device is arranged between the bottom plate and the rotating disc, and a plurality of taking and placing devices are symmetrically and fixedly connected to the rotating disc. The device is easy to operate and convenient to use, guide rollers of different sizes and models can be replaced at any time according to the machining requirement of the longitudinal welded pipe, compared with traditional longitudinal welded pipe machining, it is not needed to independently arrange a machining assembly line for the guide rollers of different sizes and models, and therefore a large amount of cost and productivity waste can be saved, and the production efficiency is improved. Meanwhile, a large amount of space can be saved.

Owner:深圳市宏仁鑫科技有限公司

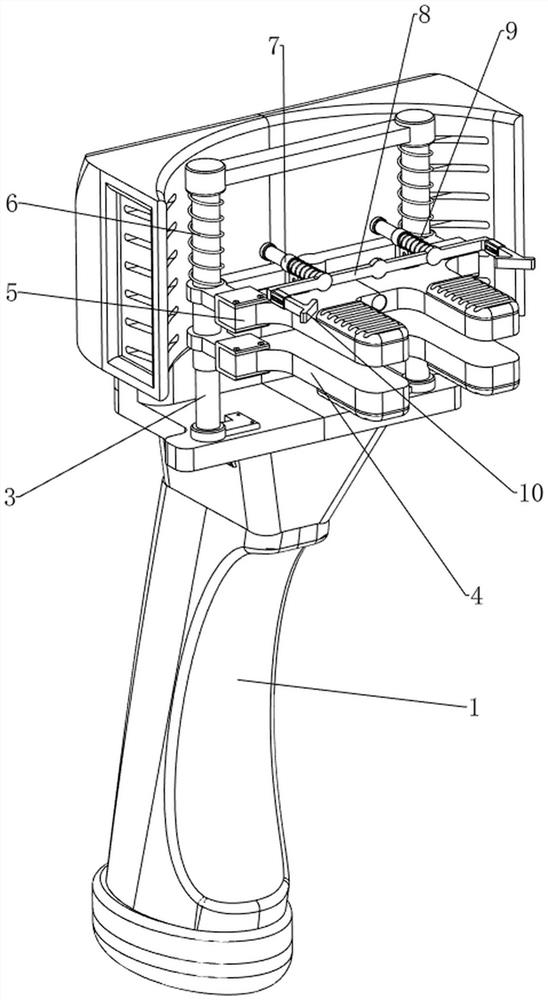

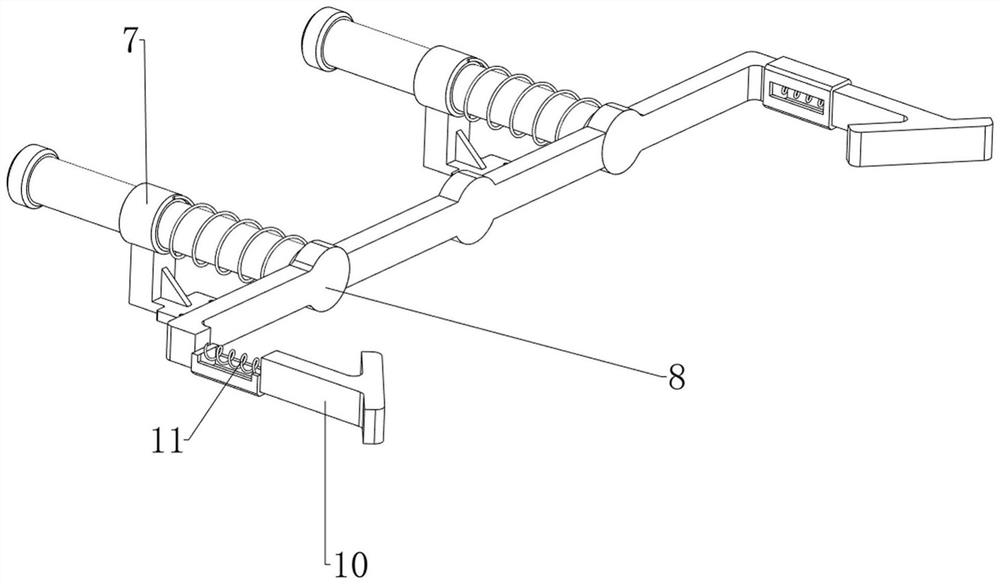

Correcting device for drawing bilateral embedded canine teeth

The invention relates to a correcting device, in particular to a correcting device for pulling burial canine teeth on two sides. The correction device for drawing the bilateral embedded canine teeth is convenient to operate, simple in structure and capable of treating the sanitation of the oral cavity of people. The correcting device for drawing double-side buried canine teeth comprises a grab handle, a sliding rod, a first fixing rod, a sliding block, first springs and the like, the sliding rod is arranged on the grab handle, the first fixing rod is arranged on the lower side of the sliding rod, the sliding block is arranged in the middle of the sliding rod in a sliding mode, the first springs are wound on the two sides of the sliding rod, and the two ends of each first spring are connected with the sliding block and the sliding rod respectively. During use, after a water pump is started, the water pump can suck liquid generated in the oral cavity of people into the liquid inlet pipe through the telescopic pipe, and the liquid flows into the water pump through the liquid inlet pipe, then flows into the liquid storage tank through the water pump and finally flows into the liquid outlet pipe through the liquid storage tank, so that the oral hygiene of people in the correction period is well maintained.

Owner:蒋均红

Digital optical processor projector and display method thereof

ActiveCN103379356BAutomatic correctionProjectorsSteroscopic systemsComputer scienceSignal processing

Owner:ACER INC

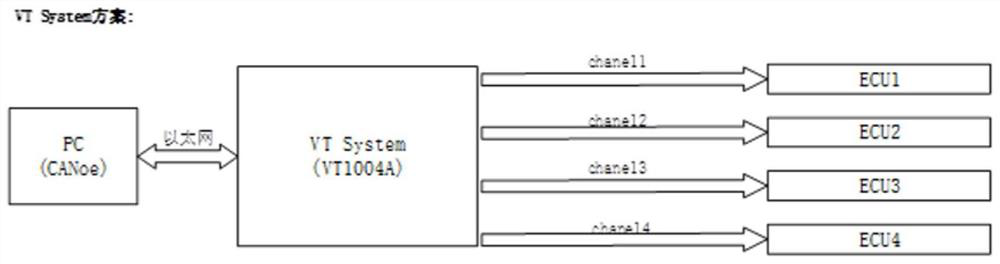

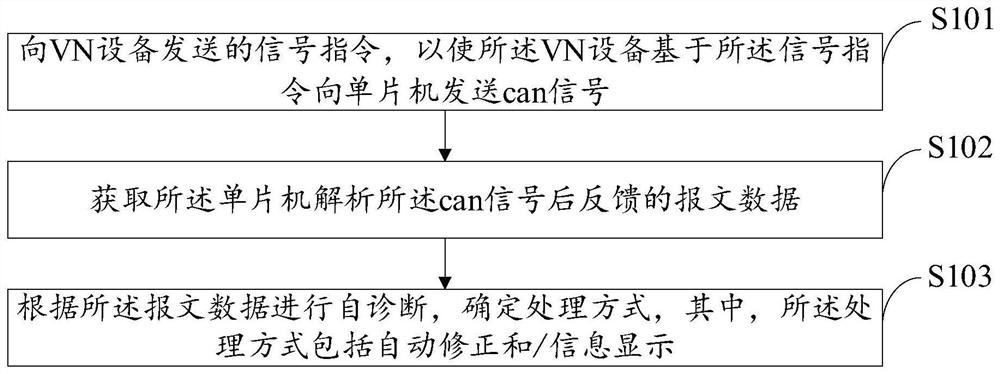

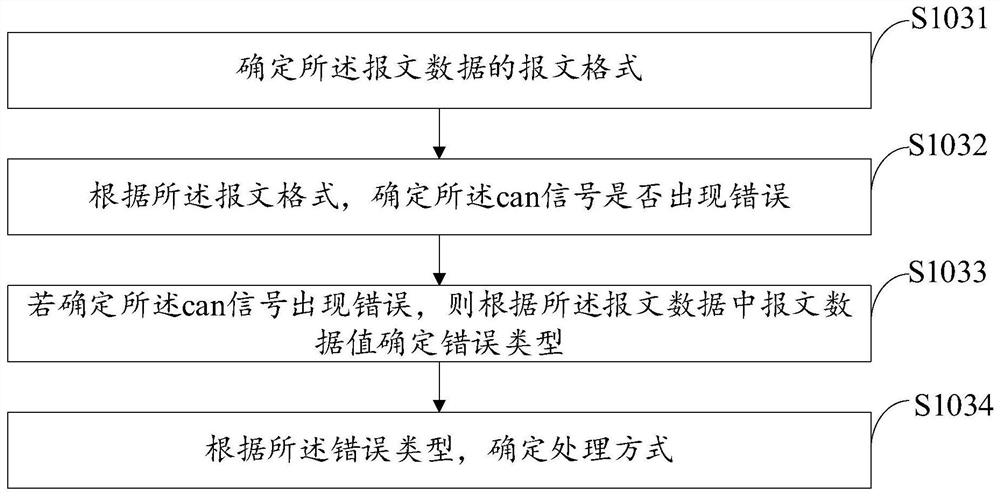

Message data processing method and device, equipment and storage medium

ActiveCN113485284AAutomatic correctionQuick checkProgramme controlElectric testing/monitoringComputer equipmentData feed

The invention discloses a message data processing method and device, computer equipment and a computer readable storage medium. The method comprises the steps: transmitting a signal instruction to VN equipment so as to enable the VN equipment to transmit a can signal to a single-chip microcomputer based on the signal instruction; obtaining message data fed back by the single-chip microcomputer after analyzing the can signal; and according to the message data, determining a processing mode, wherein the processing mode comprises automatic correction and / or information display, so that the error message can be automatically corrected through self-diagnosis of the data message, or the error message can be manually and rapidly checked through information display.

Owner:VOYAH AUTOMOBILE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com