Automatic sorting equipment for strengthening and grinding machining of workpieces

A technology for grinding and processing workpieces, which is applied in the field of automatic picking equipment for intensified grinding and processing workpieces. It can solve the problems of missed judgments in sampling surveys, easy misjudgment of workpiece surfaces, and high requirements for the skills and experience of inspectors, so as to improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

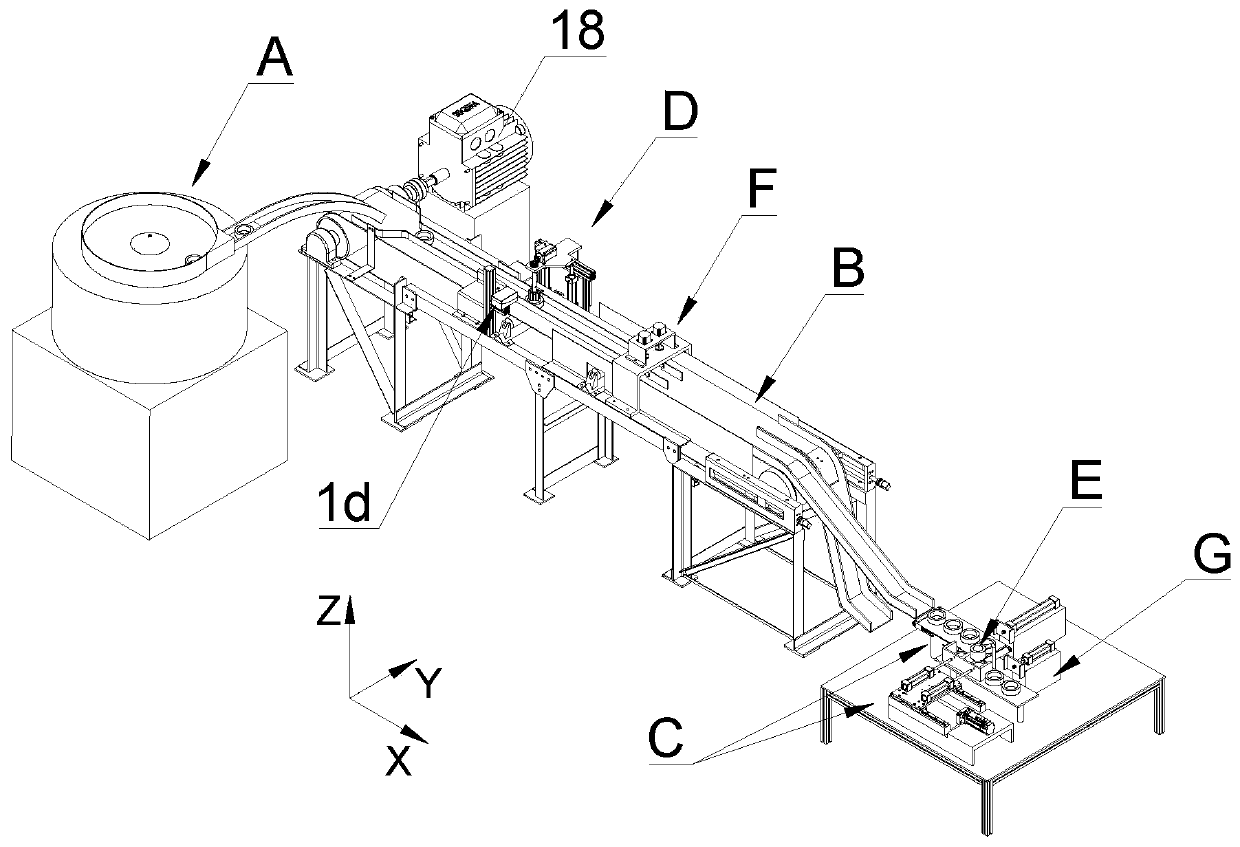

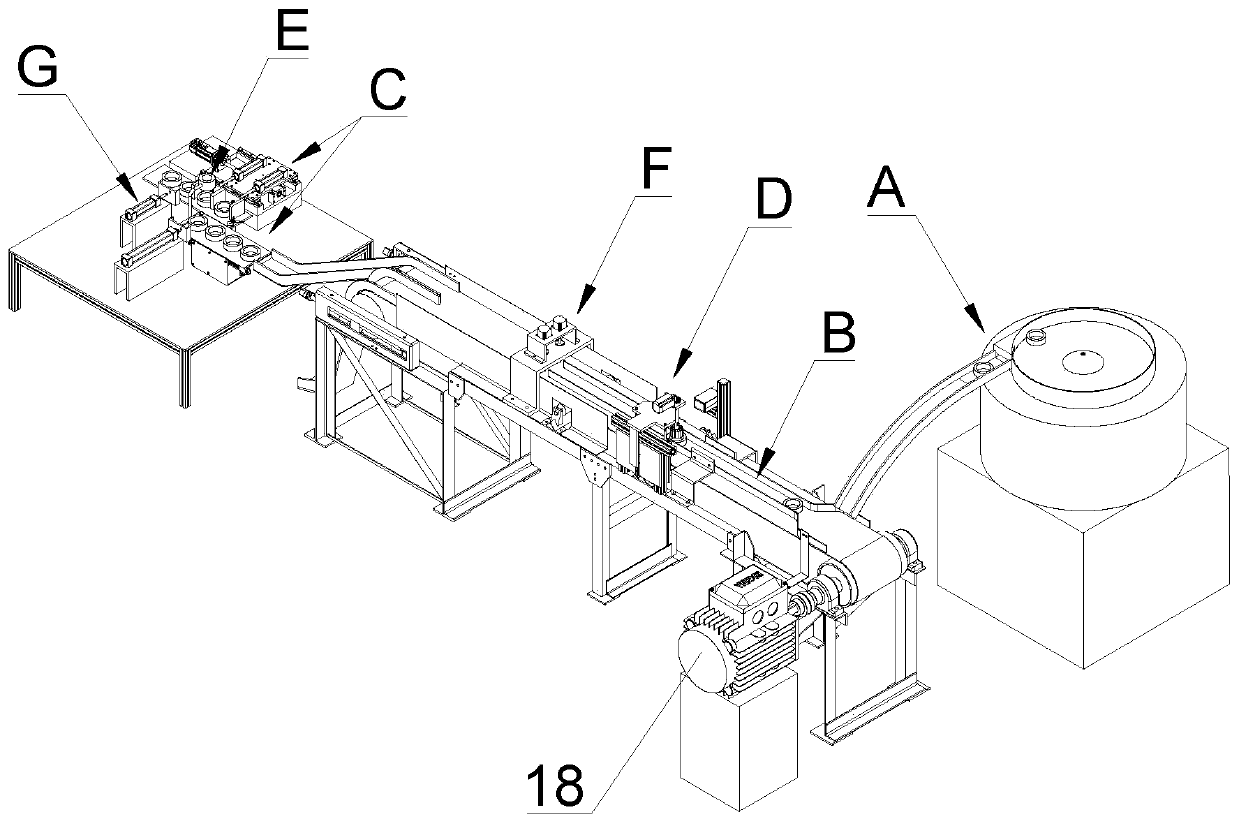

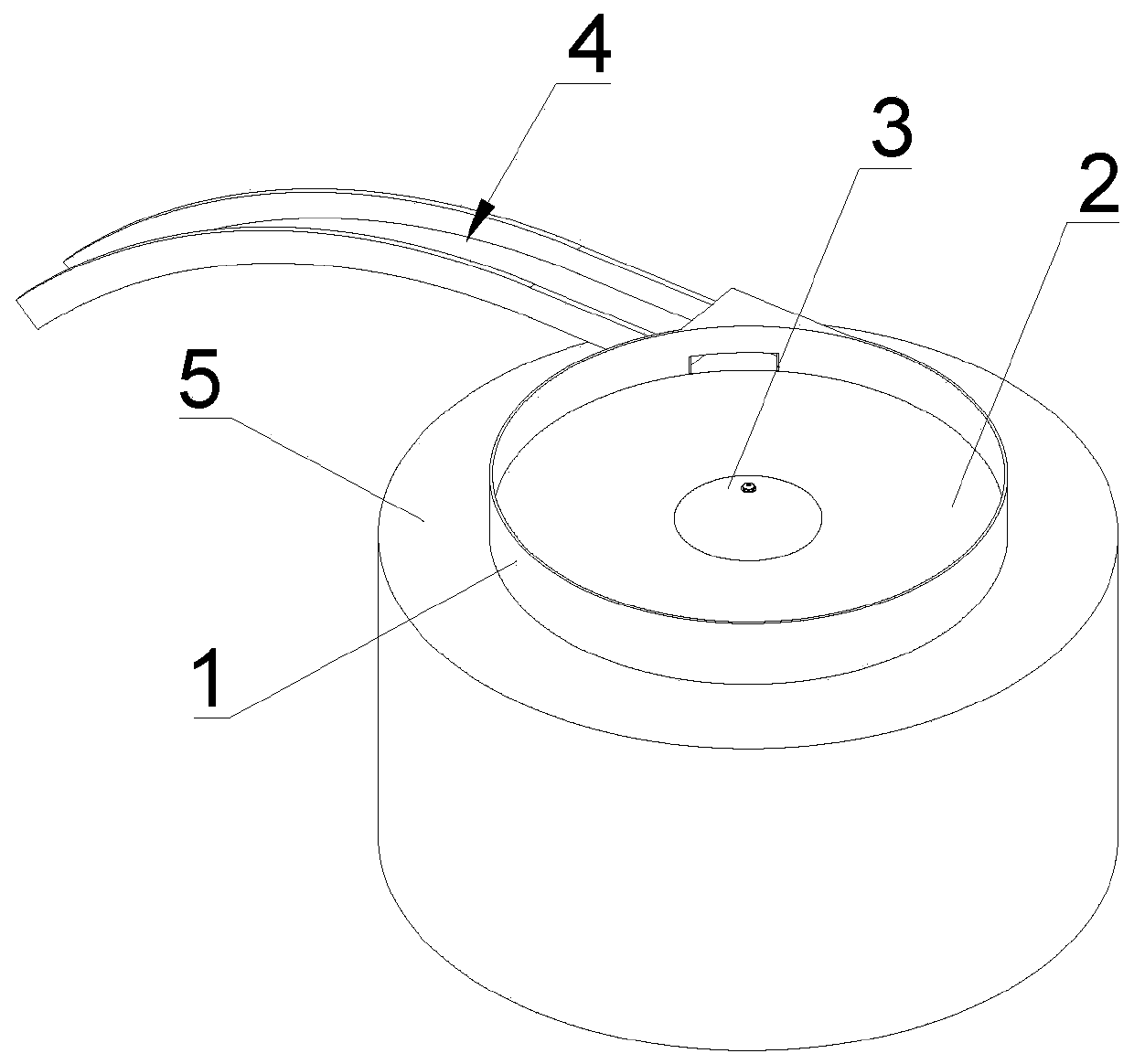

[0047] see Figure 1-6 , the automatic picking equipment for intensive grinding processing workpieces in this embodiment includes a conveying mechanism for conveying workpieces, a feeding mechanism A for automatically sending workpieces that have completed intensive grinding processing to the conveying mechanism, and a feeding mechanism for processing workpieces. A detection mechanism for detection and a rejecting mechanism for rejecting unqualified workpieces, the conveying mechanism includes a first conveying mechanism B and a second conveying mechanism C, and the detecting mechanism includes a visual sensor set on the first conveying mechanism B The detection mechanism D and the eddy current detection mechanism E arranged on the second conveying mechanism C; the rejecting mechanism includes a first rejecting mechanism F for rejecting unqualified workpieces detected by the visual inspection mechanism D and a eddy current detection mechanism for removing The unqualified workp...

Embodiment 2

[0064] The difference from Embodiment 1 is that in this embodiment, along the direction of workpiece pushing, the clamping groove 11-1 located at the rear is used to push the workpiece in the eddy current testing station to the next station, and the clamping groove 11-1 located at the front The slot 11-1 is used to further push the detected workpiece to the next station.

[0065] By setting two locking slots 11-1 on the push plate 11, two workpieces can be moved each time, so that the workpiece can be repeatedly pushed to the eddy current testing station or the eddy current testing station can be pushed down In one station, it is beneficial to improve work efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com