Automatic negative-pressure sinking method for jacket multi-tube negative-pressure tube anemometer tower composite foundation

A technology of composite foundation and negative pressure cylinder, which is applied in the direction of foundation structure engineering, caissons, measuring devices, etc., can solve the problems of low efficiency and poor reliability, and achieve the effect of direct display, efficiency and frequency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

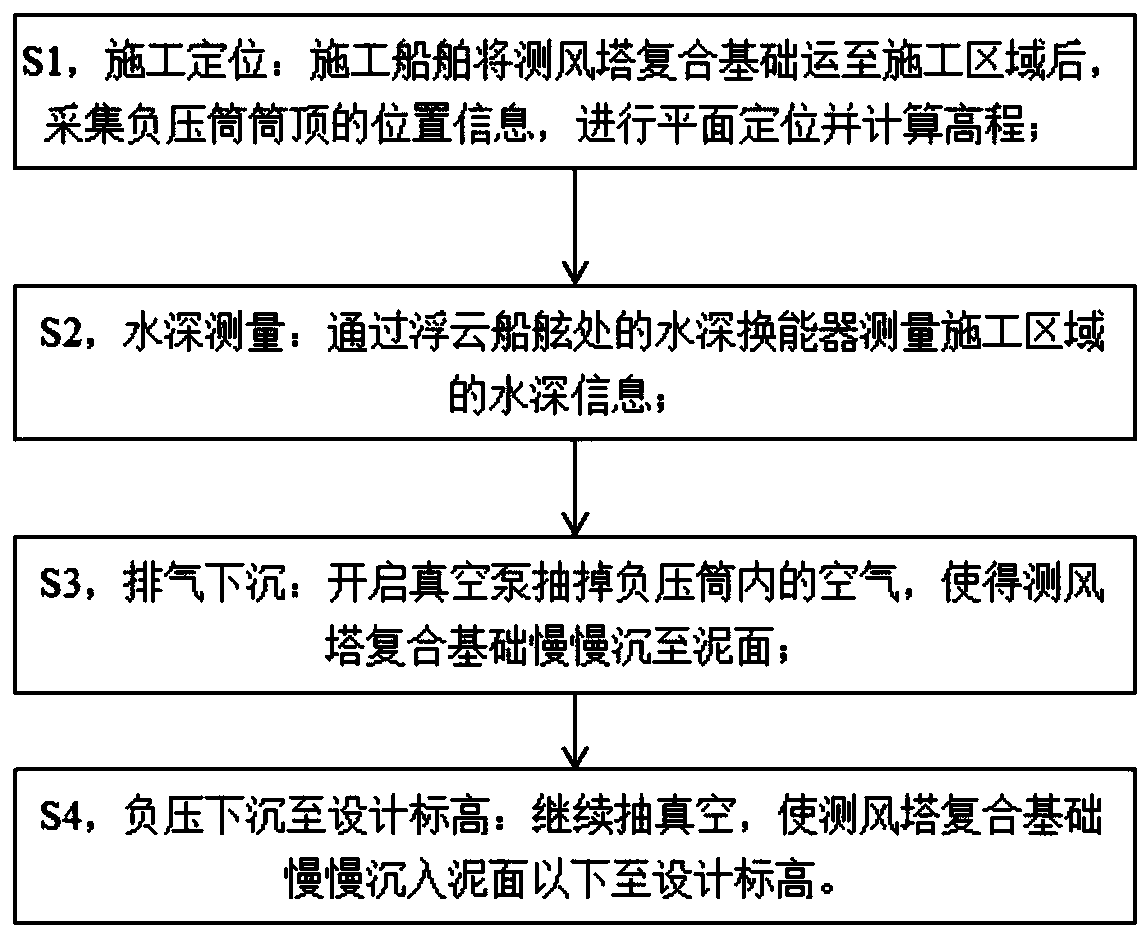

[0021] Such as figure 1 As shown, the automatic negative pressure sinking method for the composite foundation of the jacket multi-tube negative pressure tube wind measuring tower in this embodiment includes the following steps,

[0022] Step 1, construction positioning: After the construction ship transports the composite foundation of the wind measuring tower to the construction area, it collects the position information of the top of the negative pressure cylinder, performs plane positioning and calculates the elevation.

[0023] In this embodiment, the position information is obtained by using GPS-RTK positioning technology and fed back to the control system. The specific working principle is that one receiver is placed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com