Method for automatically correcting physical property parameter of photoelectric composite submarine cable material

A physical parameter, photoelectric composite technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of labor-intensive submarine cable modeling data, long correction time, cumbersome repetitive work process, etc., to achieve shortened Modeling operating cycles, reducing the effect of staffing assignments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

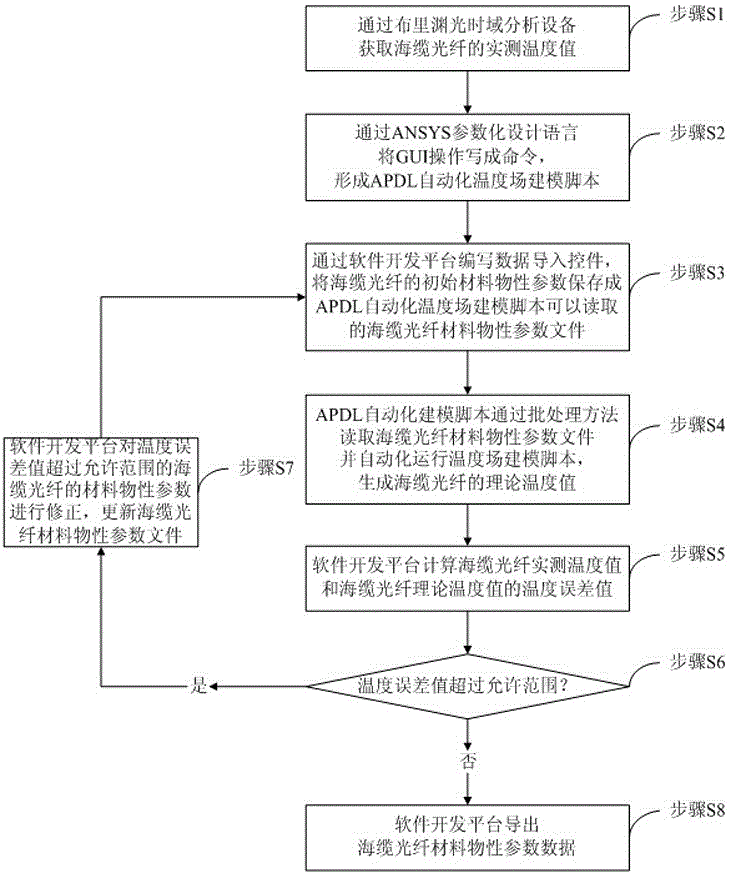

[0026] based on the following figure 1 Preferred embodiments of the present invention will be described in detail.

[0027] Such as figure 1 As shown, the present invention provides a method for automatically correcting the physical parameters of the photoelectric composite submarine cable, comprising the following steps:

[0028] Step S1. Obtain the measured temperature value of the submarine cable optical fiber through the Brillouin optical time domain analysis device (BOTDA), and save the obtained measured temperature value data of the submarine cable optical fiber into a file of the measured temperature value of the submarine cable optical fiber.

[0029] In this embodiment, the Brillouin optical time-domain analysis device BOTDA takes 20A as the current difference, takes 10 groups of submarine cable optical fiber measured temperature values in the range of 100A-280A, and saves them as text PraFiber.txt.

[0030] Step S2, using ANSYS parametric design language to write...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com