Component for a machine tool, machine tool and method for identifying wear

A component and machine tool technology that is applied to presses, mechanical equipment, and testing wear resistance, etc., can solve problems such as deterioration of conditions and achieve high processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

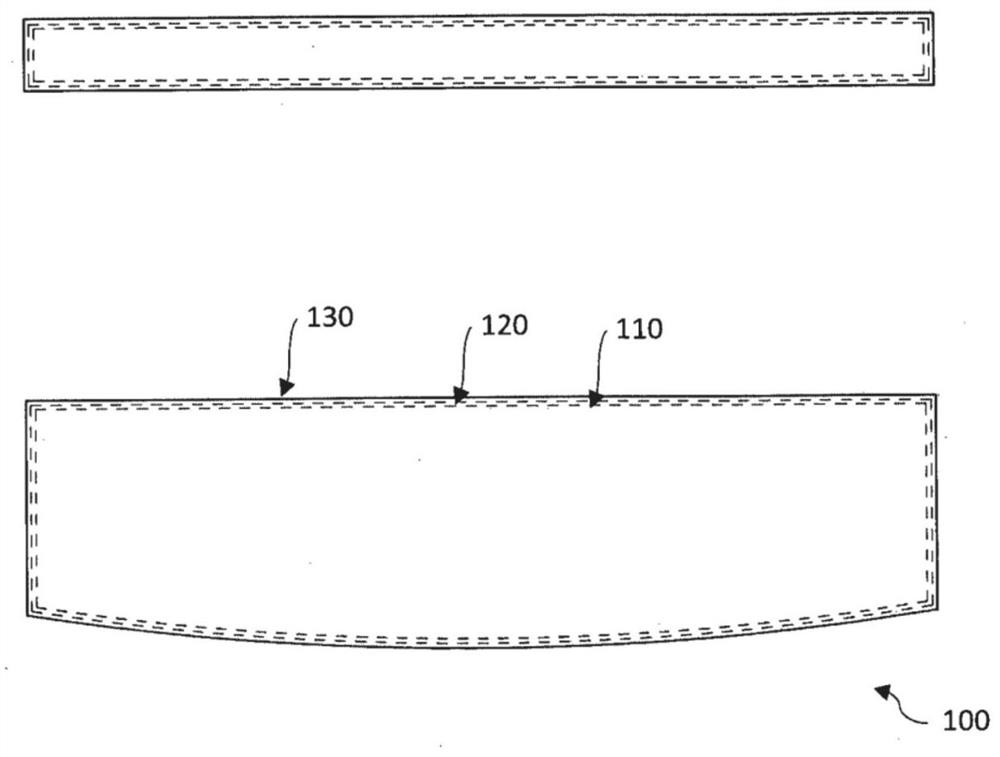

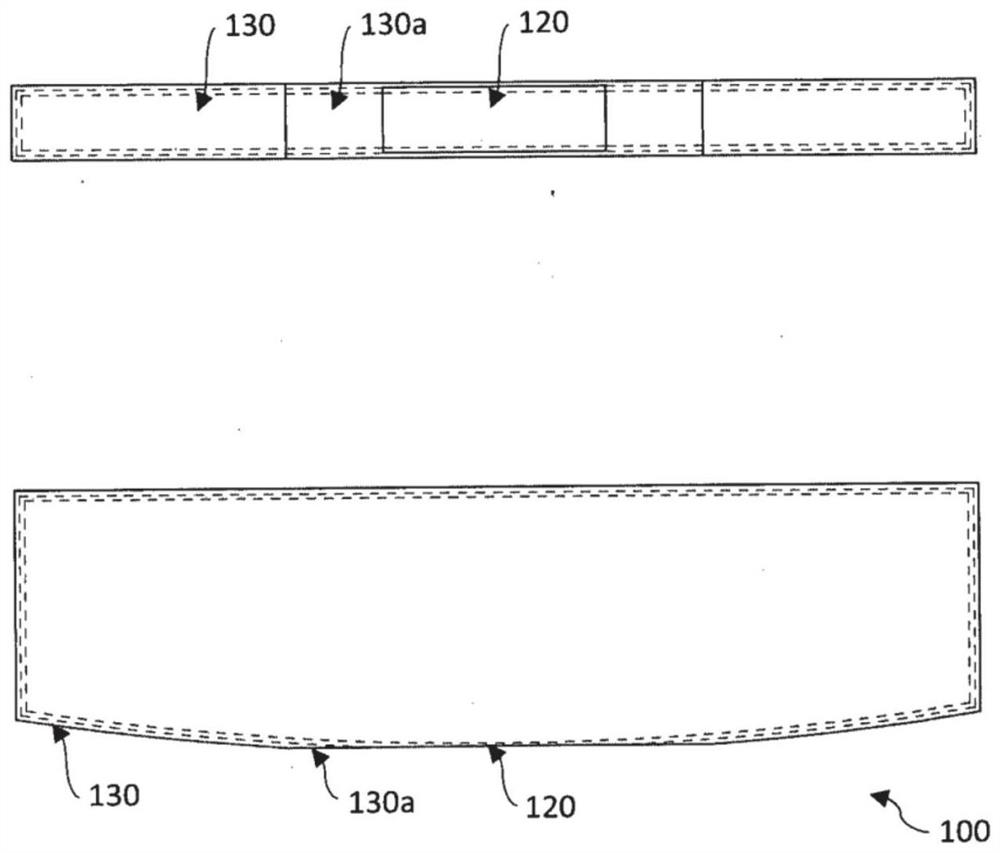

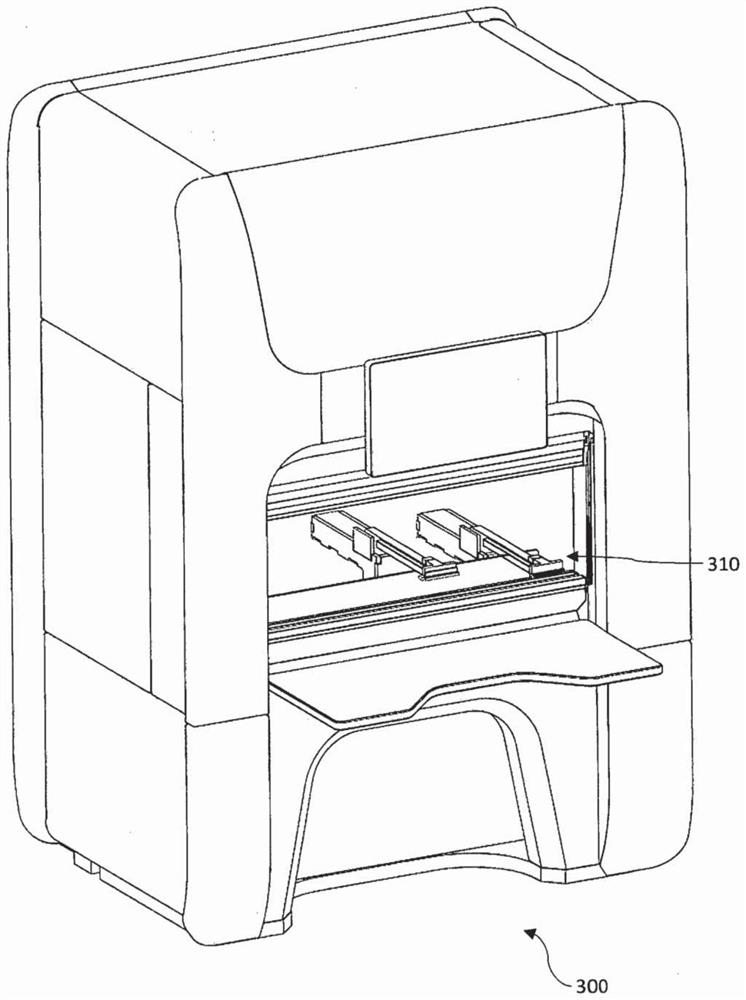

[0040] figure 1 A schematic front view and a plan view of a component 100 are shown, which have a component core or component base body 110 and optical wear indicators 120 , 130 applied thereto. The component 100 can be a wear part of a bending machine, in particular a tool, a machine table and / or a stop element such as a stop finger. Correspondingly, the wearing part of the bending machine can comprise the base body 110 and the optical wear indicators 120 , 130 arranged thereon.

[0041] Depending on the intended use, the component 100 is provided with an outer hard material layer or a sacrificial layer 130 . Examples of materials here include PVD and / or CVD hard material layers or materials such as titanium nitride. The layer thickness is selected according to the application and the expected component wear. The layer thickness is advantageously from 1 to 10 micrometers and especially advantageously from 1 to 20 micrometers. In addition, larger layer thicknesses can also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com