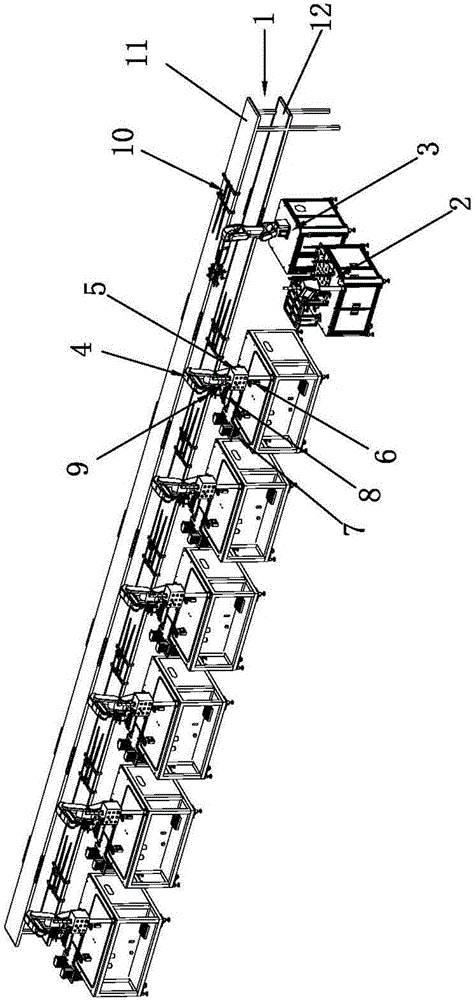

Automatic polishing production line of mobile phone shells

A mobile phone case and assembly line technology, applied in the direction of grinding machine parts, grinding machines, grinding racks, etc., can solve the problems of crushed products, low precision of manual grinding, and different people, saving manpower and material resources, Improve production efficiency and production safety, and facilitate accurate handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below with reference to the embodiments and the accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention. The present invention will be described in detail below with reference to the accompanying drawings.

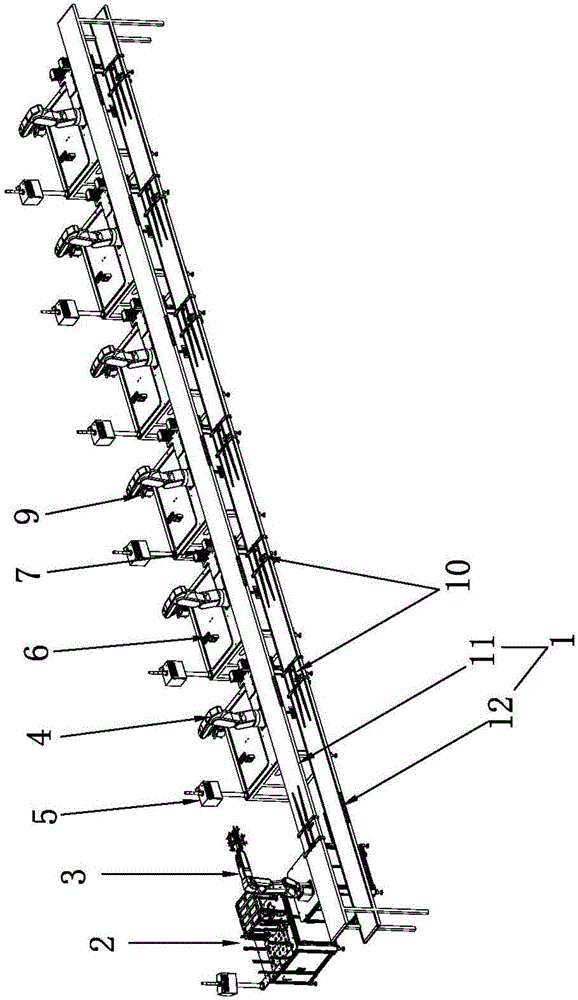

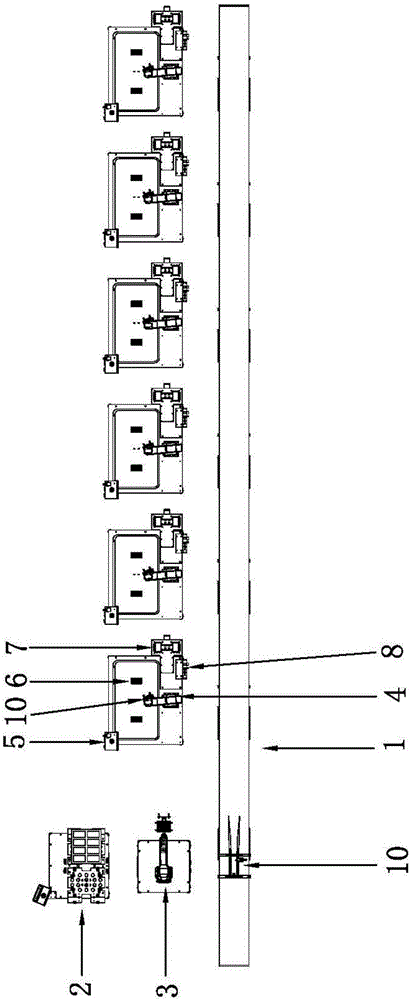

[0059] like Figure 1 to Figure 3 As shown, the present invention provides an automatic polishing line for a mobile phone case, which includes a conveying mechanism 1, which includes an upper conveying belt 11 and a lower conveying belt 12, and the upper conveying belt 11 and the lower conveying belt 12 move in opposite directions, In this embodiment, the unpolished mobile phone case is placed on the lower conveyor belt 12 and then transferred to the automatic grinding machine, and the mobile phone case polished by the automatic grinding machine is put back on the upper conveyor belt 11 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com