Sheet post-processing apparatus and sheet post-processing method

A post-processing device and post-processing technology, applied in thin material processing, binding, book binding, etc., can solve the problems of the maximum number of sheets and the inability to set paper on the pasting mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

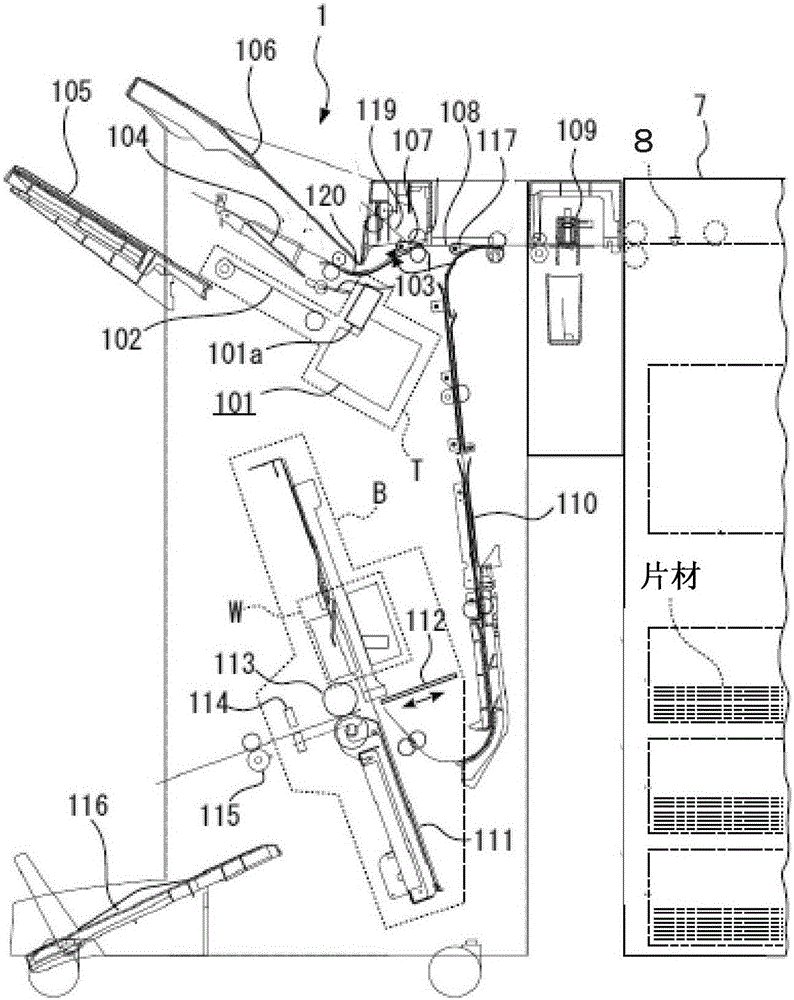

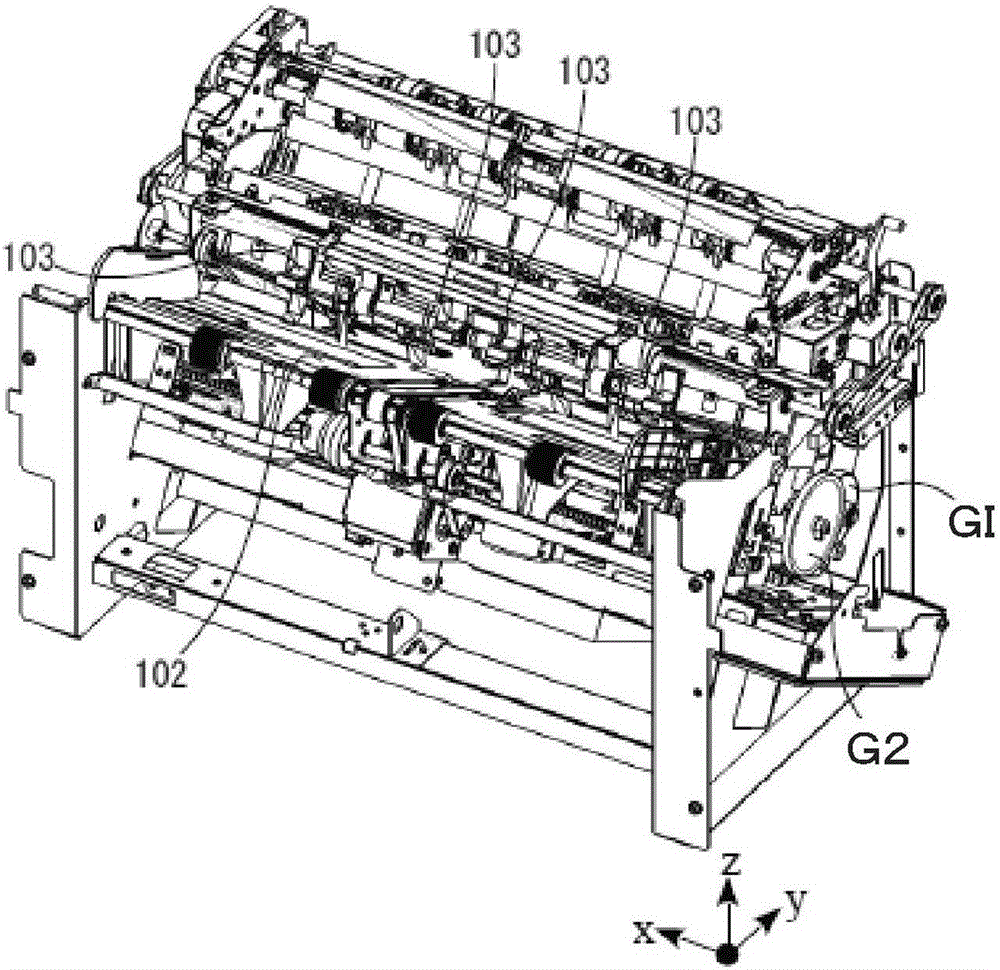

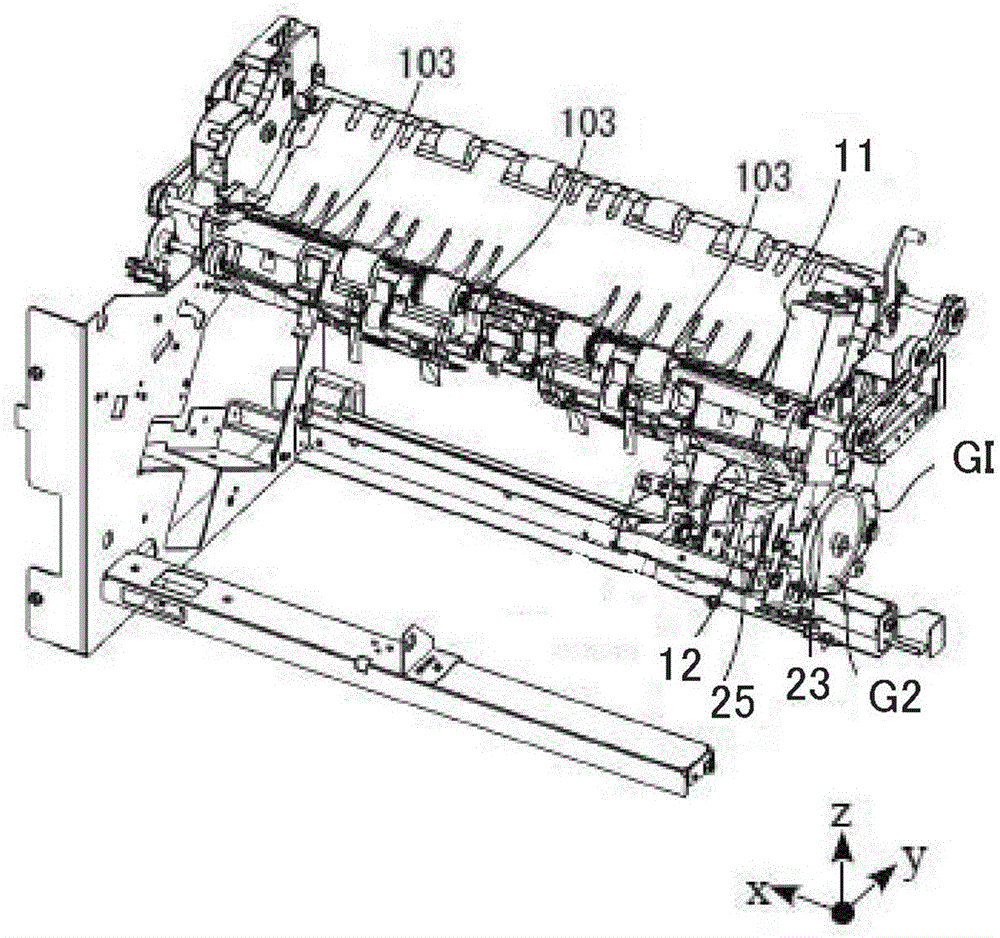

[0016] This embodiment provides a sheet post-processing device that continuously receives a certain number of sheets instructed to be printed and performs stapling processing. The sheet post-processing device includes: The permissible binding number of sheets, and each supplied sheet is glued and bound; the counter counts the number of continuously received sheets; and the controller, according to the number of sheets instructed by printing number and the allowable number of binding sheets of the sheets to obtain the excess number of sheets, compare the excess number of sheets with a predetermined excess number of sheets set in advance, and set A first mode is set, and the first mode causes the binding unit to perform binding with the number of sheets indicated for printing as a bundle.

[0017] This embodiment provides a sheet post-processing method, which continuously receives a certain number of sheets instructed by printing, and performs binding processing, wherein the num...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com