A mechanical chisel trigger breaker

A mechanical, breaker technology, applied in mechanically driven excavators/dredgers, earth movers/shovels, roads, etc., can solve problems such as increased equipment operating costs, damage to drill rods, and inability to release the kinetic energy of beating , to achieve the effect of preventing empty play and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

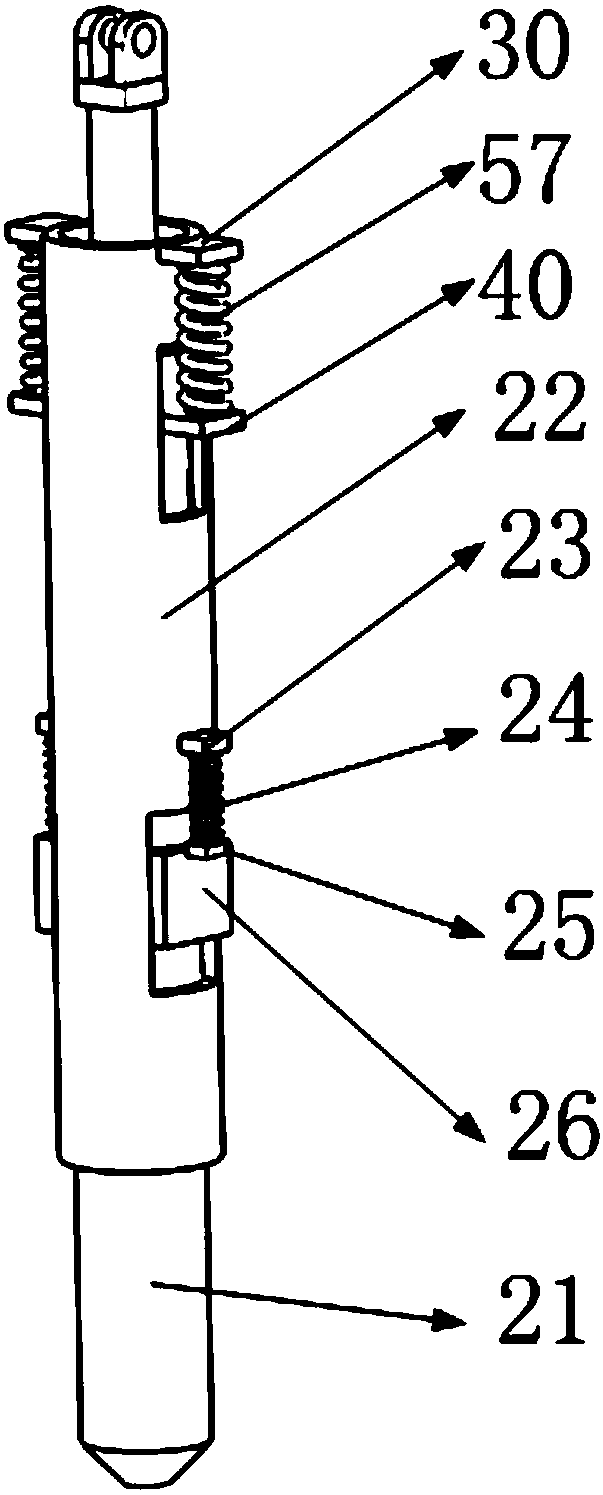

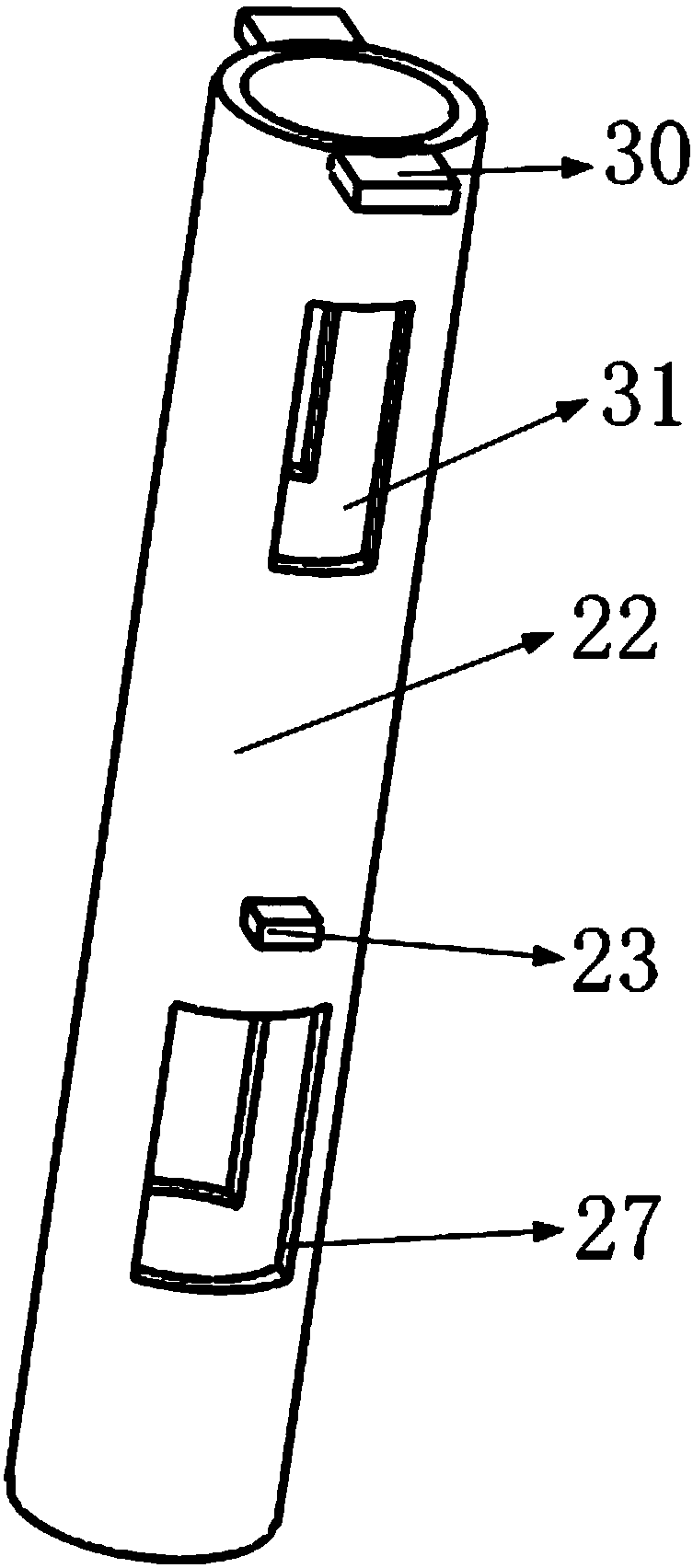

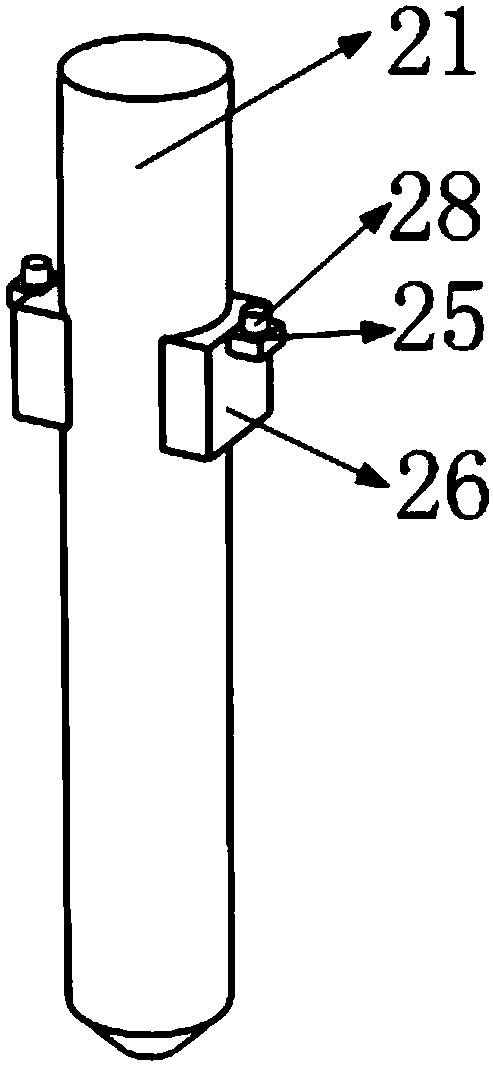

[0030] Such as Figure 10 , 11 As shown, it includes rocker swing hole, clutch, trigger rod, drill rod, drill rod sleeve, first drill rod spring support, drill rod spring, second drill rod spring support, drill rod guide block, drill rod sleeve sliding hole , spring pin, first impact hammer spring support, impact hammer chute, drive rod, drive rod guide rail, drive rod limit plate, impact hammer, impact hammer spring pin, second impact hammer spring support, drive rod limit block, Impact hammer protection spring, drive rod guide rail groove, drive rod limit groove, hydraulic pump, crank fixing structure, crank spring, rocker shaft, rotary pair, crank, crank slider, slider limit ring, first outer plate, The second outer plate, side plate reinforcement rib, impact hammer reciprocating spring, side plate connecting plate, rocker, among which Figure 10 As shown, the first outer panel and the second outer panel are symmetrically installed together through several side panel rein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com