Valve Linear Actuators and Valves

A linear actuator and driver technology, applied in the direction of lift valve, valve detail, valve device, etc., can solve the problems of reducing the sealing closing force, the valve linear actuator or its driving unit stuck, blocked, etc., to achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

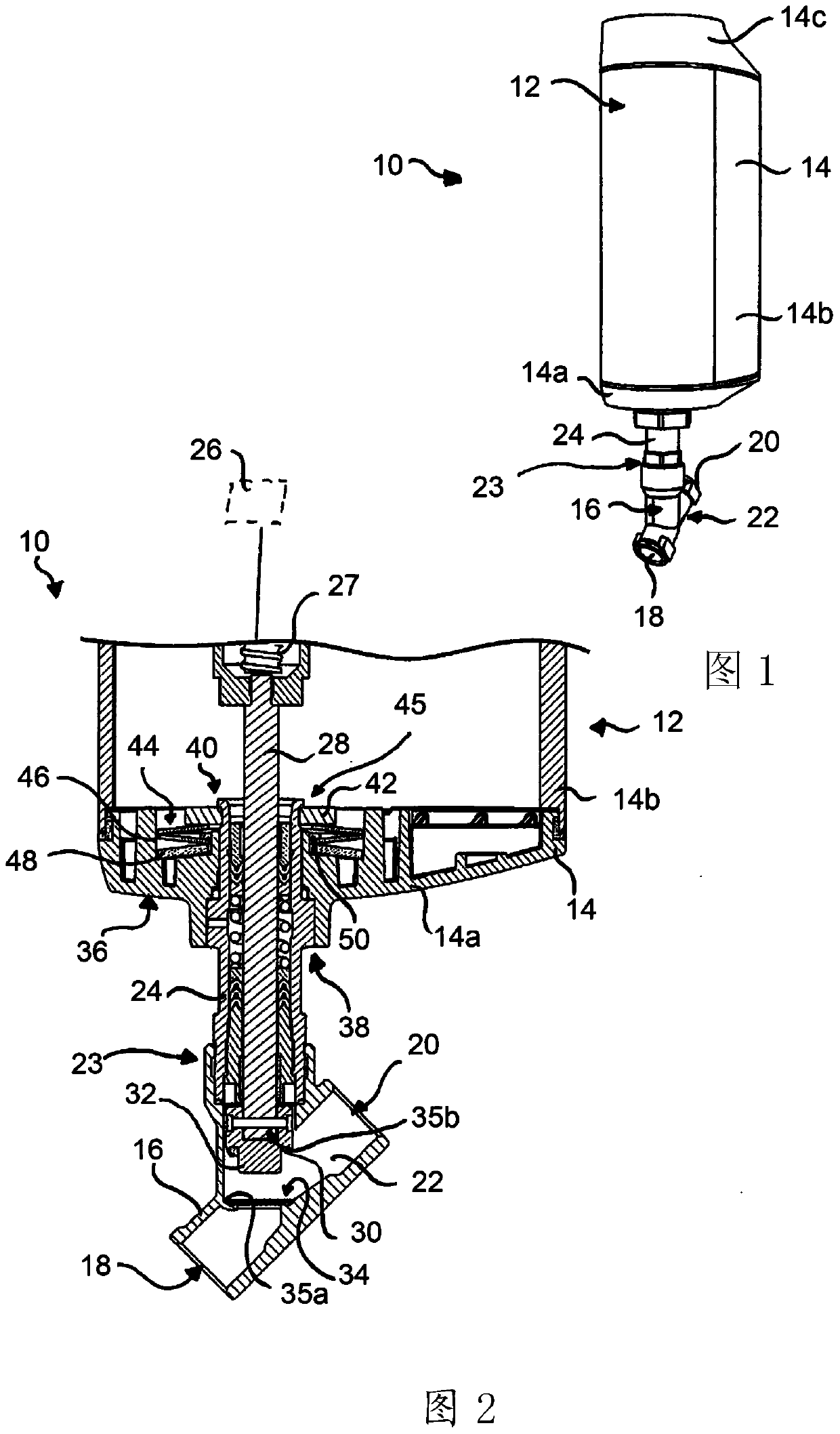

[0039] FIG. 1 shows a valve 10 which includes a valve linear drive 12 with a drive housing 14 and a valve body 16 .

[0040] Valve body 16 has an inlet 18 and an outlet 20 . A flow channel 22 is formed between the inlet 18 and the outlet 20 , through which a fluid can flow and which can be provided by the valve 10 , in particular to regulate or control the flow of the fluid.

[0041] The valve body 16 is connected to the separately constructed valve linear drive 12 via a coupling point 23 which is arranged on a support unit 24 of the valve linear drive 12 . In the illustrated embodiment, the support unit 24 is formed separately from the drive housing 14 and separately from the valve body 16 , as is externally shown in FIG. Valve 10 is shown in .

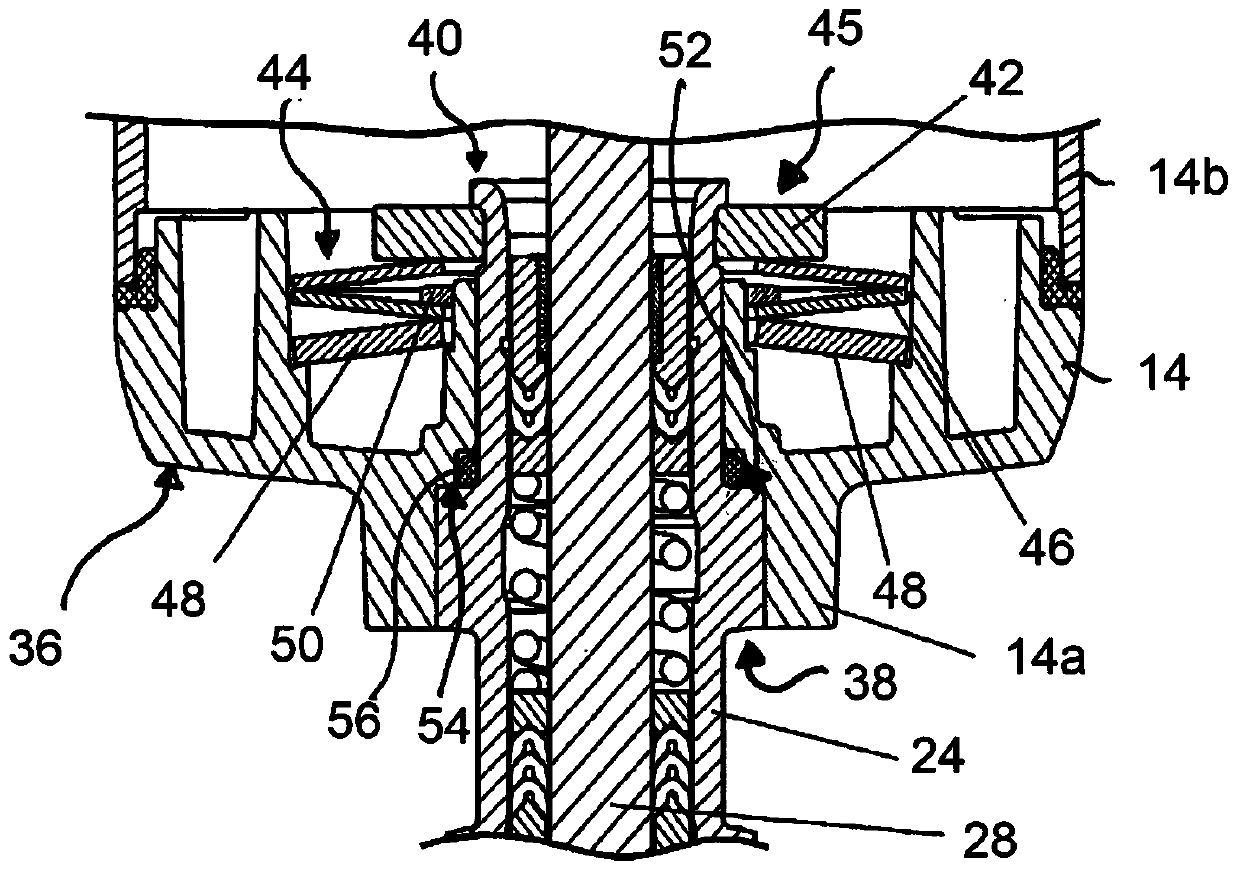

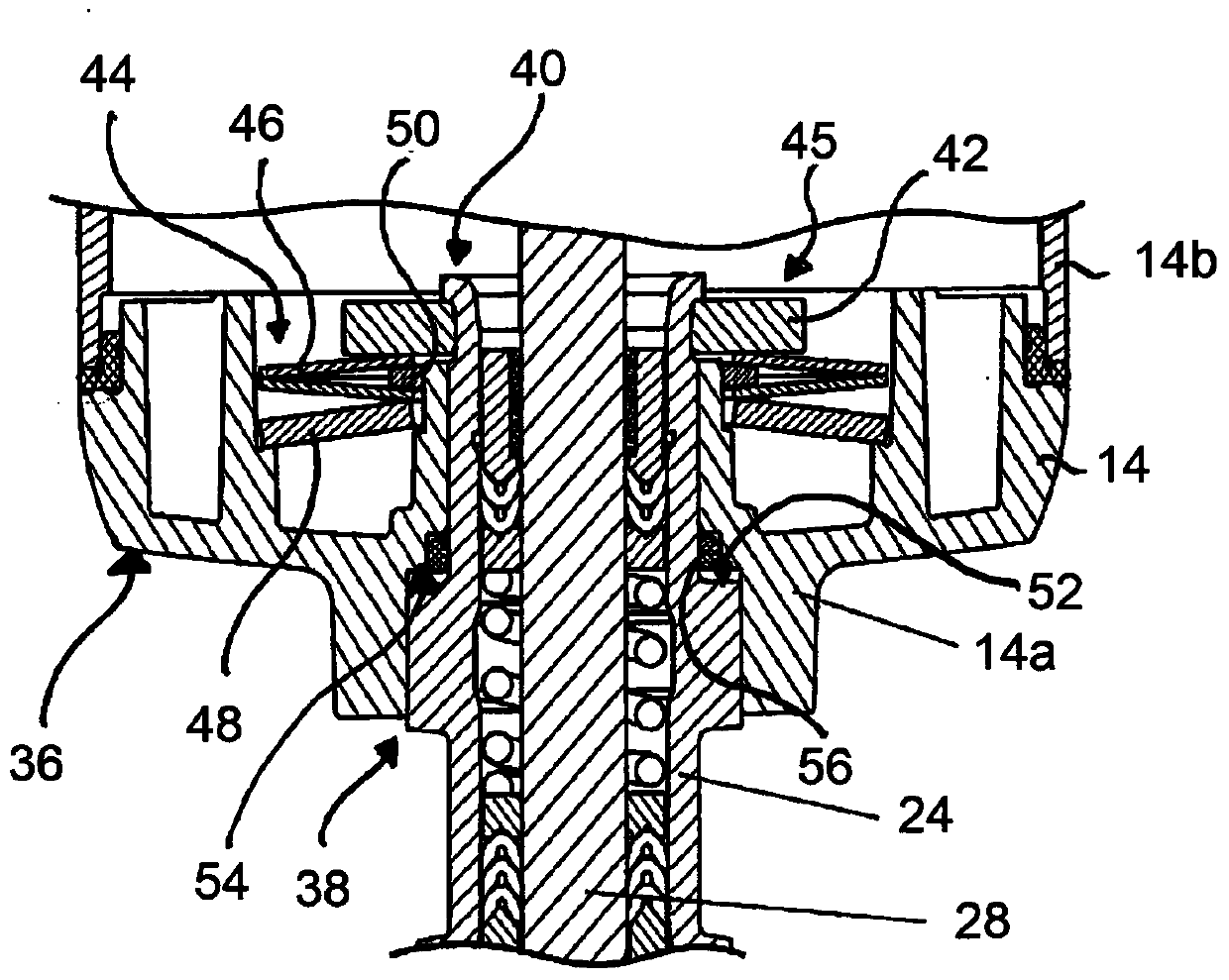

[0042] FIG. 2 shows that the valve linear drive 12 has a drive unit 26 , which is shown in dashed lines in FIG. 2 . An axially displaceable actuating element 28 is coupled to the drive unit 26 and can be driven by the drive unit 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com