A waterway docking structure on the injection mold of chopsticks

A technology of injection mold and waterway, which is applied in the field of daily tableware preparation, can solve problems such as easy water leakage, affecting product molding, and poor sealing effect of sealing rings, so as to prevent water leakage, increase safety, and solve the effects of easy water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

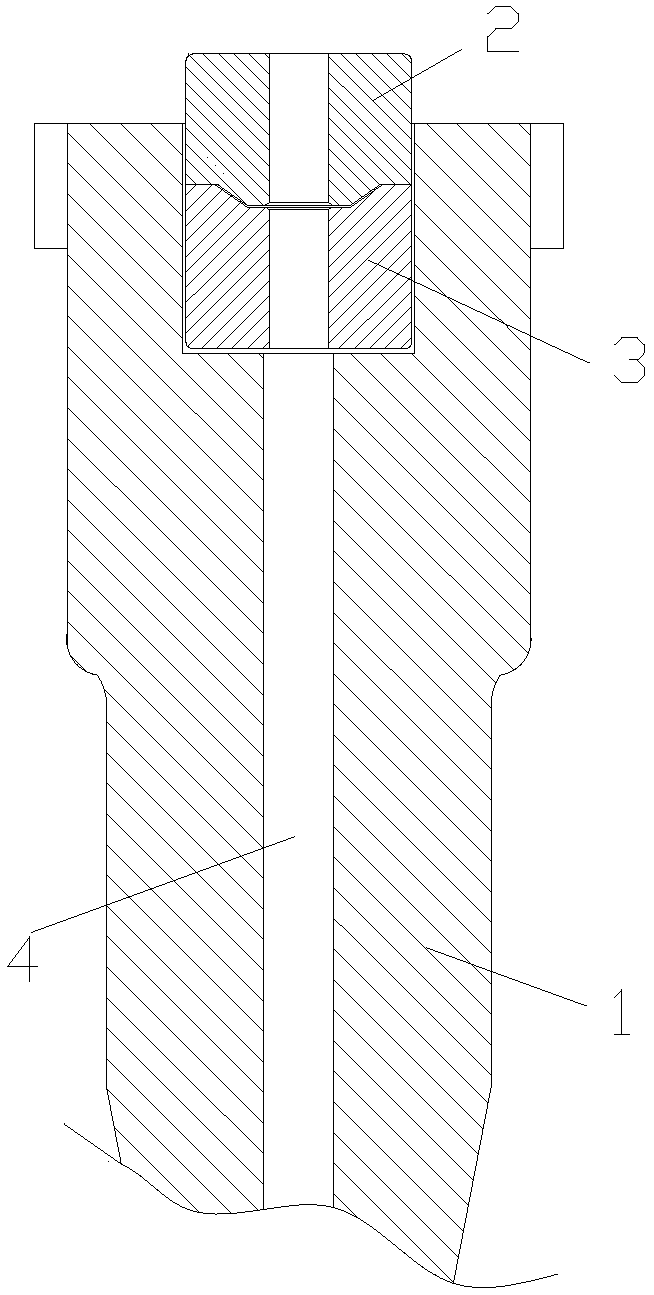

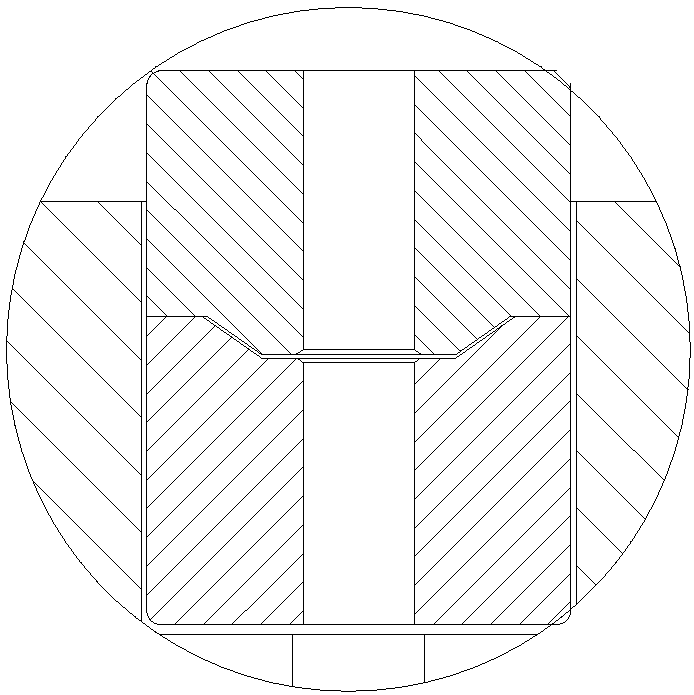

[0014] Please refer to the attached Figures 1 to 3 , the embodiment of the present invention includes:

[0015] A waterway docking structure on an injection mold for chopsticks, comprising a fixed mold core 1, a male joint 2 and a female joint 3. The fixed mold core 1 comprises a molding part and an installation part, and the installation part is a stepped revolving body. The shaft core of the fixed mold core 1 is provided with a waterway 4, and the waterway 4 is opened from the rear end face of the fixed mold core 1. The axial direction of the mold core 1 extends toward the front end of the fixed mold core. The design of the waterway 4 is to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com