Film covering mechanism

A technology of a film coating mechanism and a cylindrical shell, which is applied in the field of film coating mechanism, can solve the problems of complex film coating mechanism, no adjustment part, and inability to adjust the gap of the product coating film, etc., and achieves the effects of easy operation, simple adjustment mechanism, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

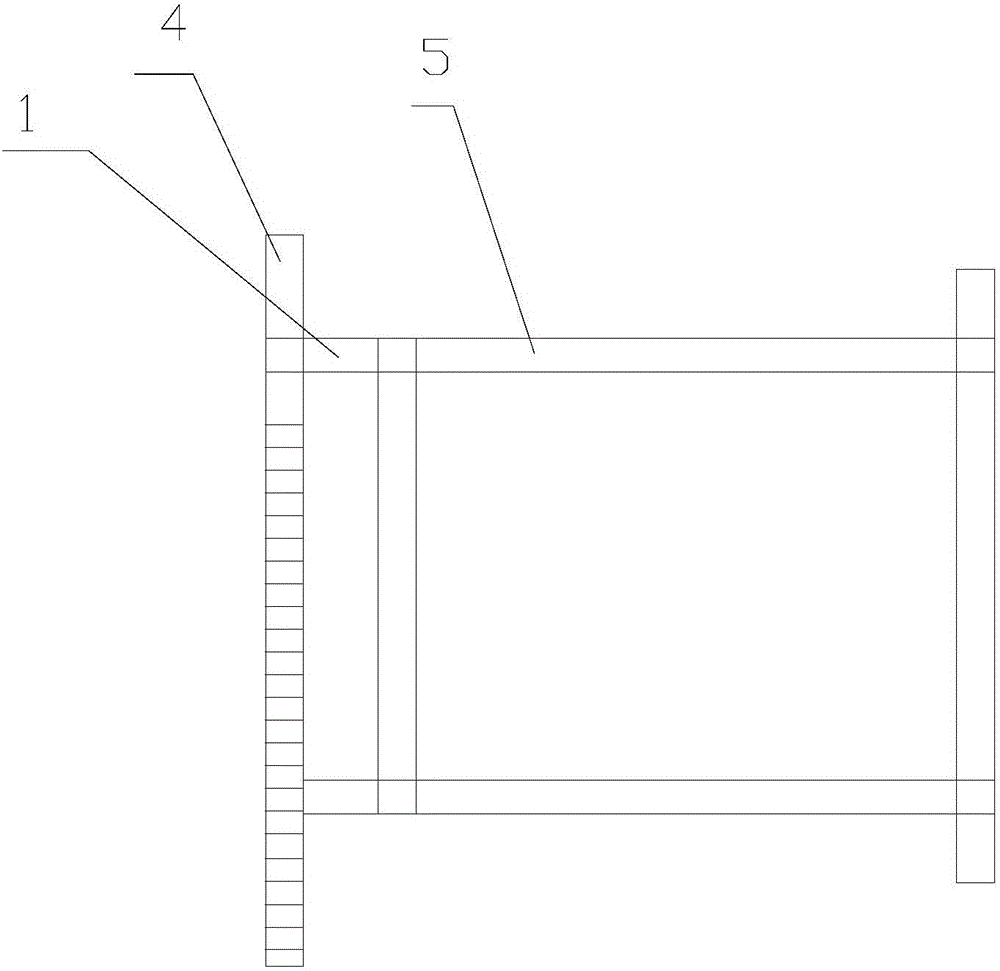

[0022] In the present invention, unless stated otherwise, the used orientation words such as "up, down, left, right" usually refer to figure 1 Up and down and left and right are shown. "Inner and outer" refer to the inner and outer on the specific outline. "Far and near" refer to far and near relative to a certain component.

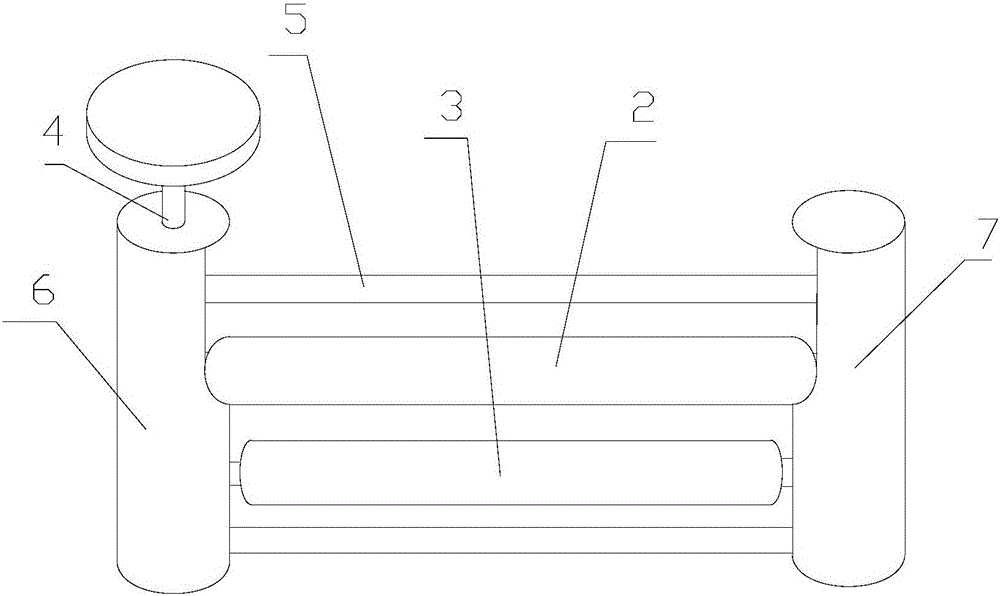

[0023] The present invention provides a film covering mechanism, which comprises: a socket 1, a moving roller 2, a fixed roller 3, an adjusting screw 4 and a support frame 5, and one side of the support frame 5 passes through the socket 1 is sleeved on the adjusting screw 4, and moves along the length direction of the adjusting screw 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com