Magnetostrictive following turning mechanism

A magnetostrictive and follow-up steering technology, applied in lighting and heating equipment, transportation and packaging, optical signals, etc., can solve problems such as difficult promotion, poor reliability, and high cost, and achieve simplified adjustment mechanism, simplified structure, and sensitive transmission Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

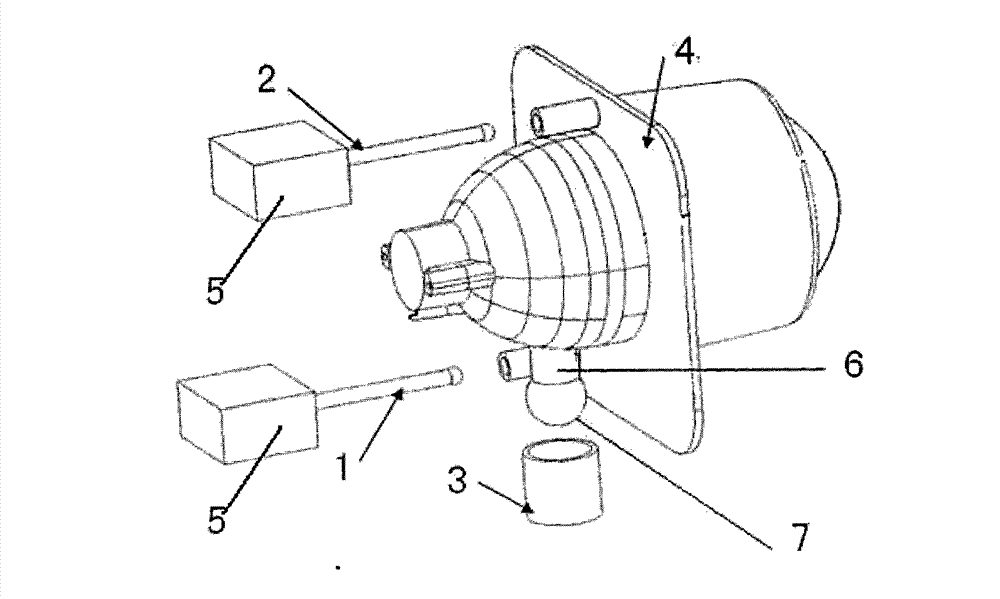

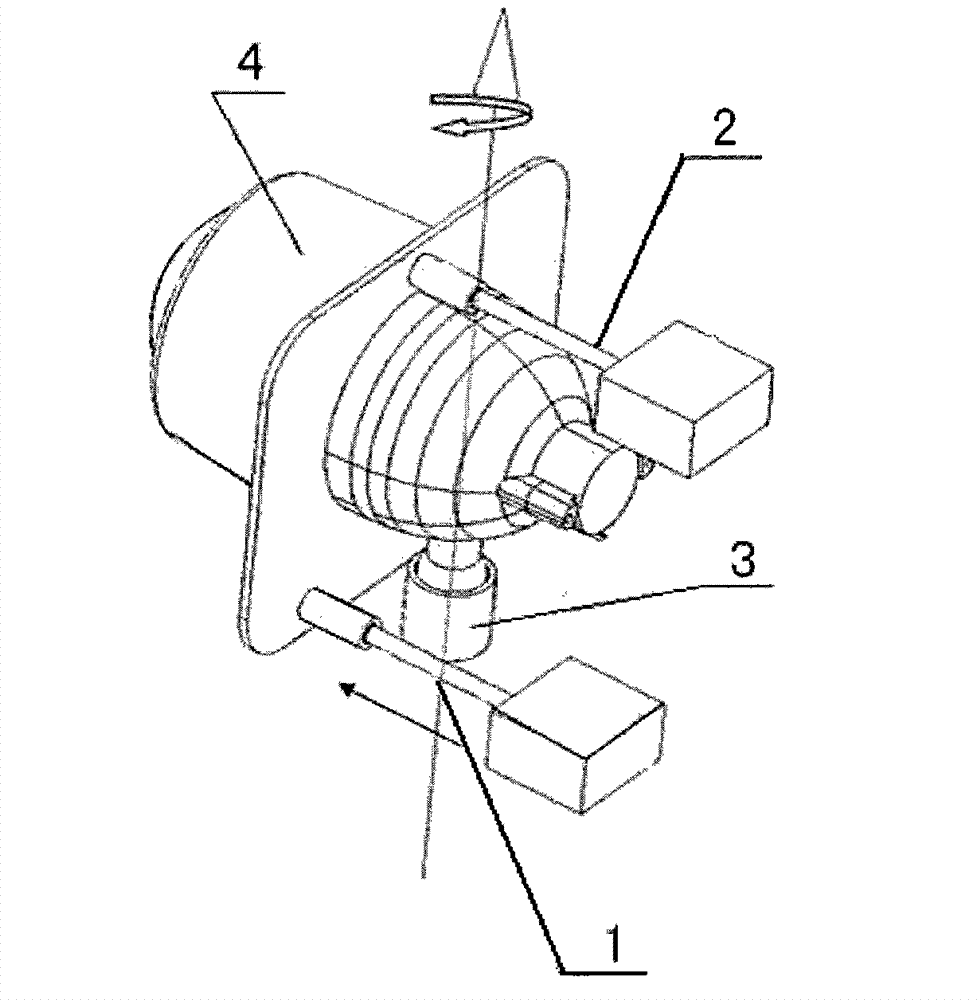

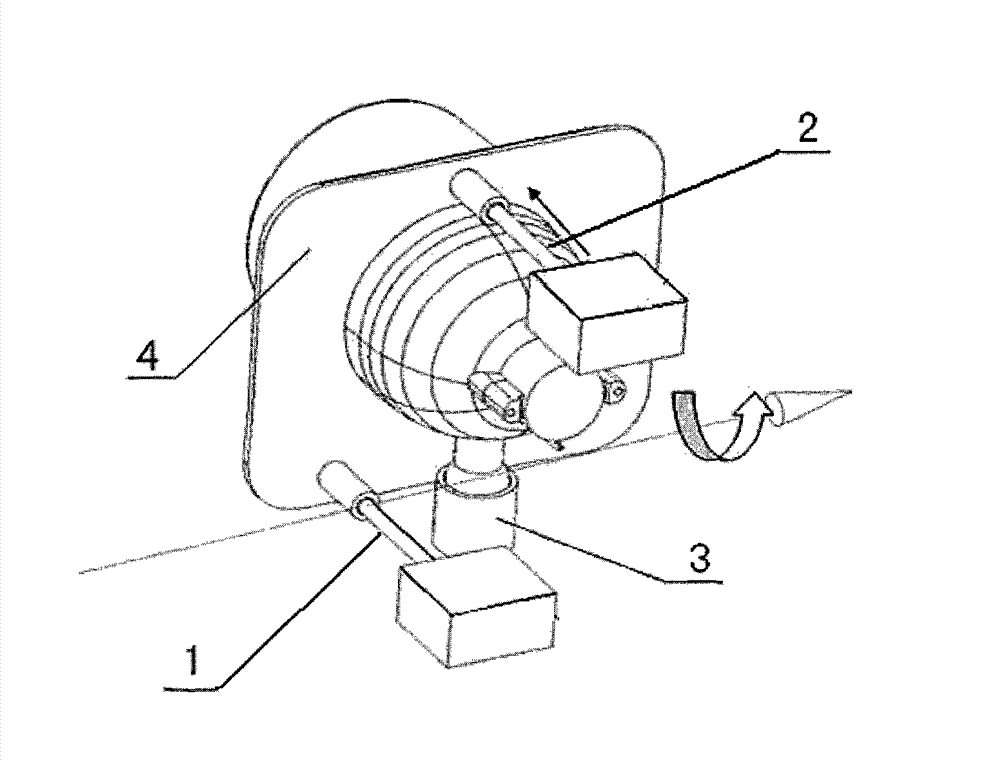

[0017] as attached figure 1 As shown, the magnetostrictive follow-up steering mechanism of the present invention includes a spherical base 3, a left and right magnetostrictive rod 1, an upper and lower magnetostrictive rod 2, a xenon lamp lens group 4, a spherical bracket 6, a ball head 7 and an electromagnetic module 5; It is characterized in that: the left and right magnetostrictive rods 1 and the upper and lower magnetostrictive rods 2 are respectively arranged on the lower and upper parts of the frame of the xenon lamp lens group 4, and the lower part of the lamp bowl of the xenon lamp lens group 4 is provided with a spherical bracket 6, and the spherical surface The bottom of the bracket 6 is provided with a ball head 7, the ball head 7 can rotate in the spherical base 3, and the left and right magnetostrictive rods 1 are driven to extend or shorten by the electromagnetic module 5, so as to realize the left and right movement of the xenon lamp lens group 4; The module 5 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com