Novel dirt transfer system

A new type of waste technology, applied in water conservancy projects, open water surface cleaning, construction, etc., can solve the problems of wasting time and affecting work efficiency, saving time and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

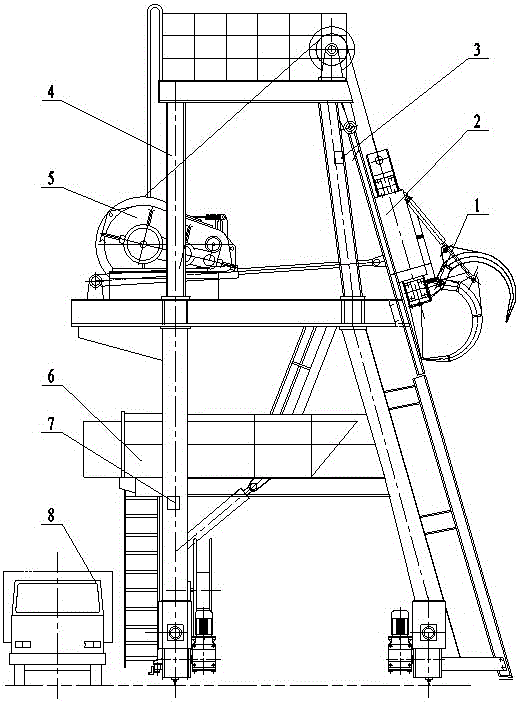

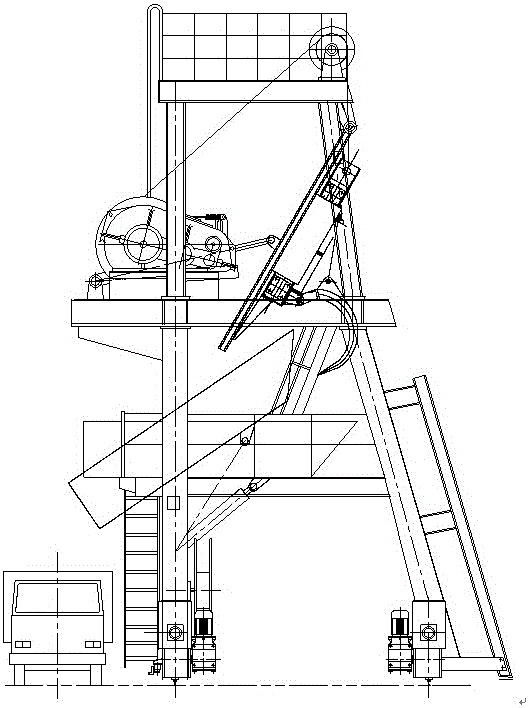

[0016] Such as Figure 1-Figure 2 As shown, a new type of dirt transfer system includes a door frame 4, the door frame 4 is provided with a cleaning grab 1 and a lifting mechanism 5 connected with the cleaning grab 1, and the lifting mechanism 5 is set on the door frame 4 On the middle platform of the mast 4, a flap 2 is also provided on the mast 4, a lower platform is provided on the mast 4, and a dirt collecting bucket 6 for collecting dirt in the cleaning grab 1 is provided on the lower platform.

[0017] The front side of the mast 4 is provided with a guide rail for the movement of the cleaning grab 1.

[0018] The guide rail includes a lower guide rail and an upper guide rail. The lower guide rail is arranged on the door frame 4 and the upper guide rail is arranged on the flap 2.

[0019] The upper end of the flap 2 is hinged on the door frame 4, and a trough structure is provided on the flap 2, and the guide wheels on the cleaning grab 1 can roll into the trough structure.

[0...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap