A motor rotary switch

A rotary switch and rotary shaft technology, applied in electrical switches, circuits, electrical components, etc., can solve the problems of reduced electrical safety, many components, complicated wiring, etc., and achieve the effect of simple wiring, few components, and high electrical safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

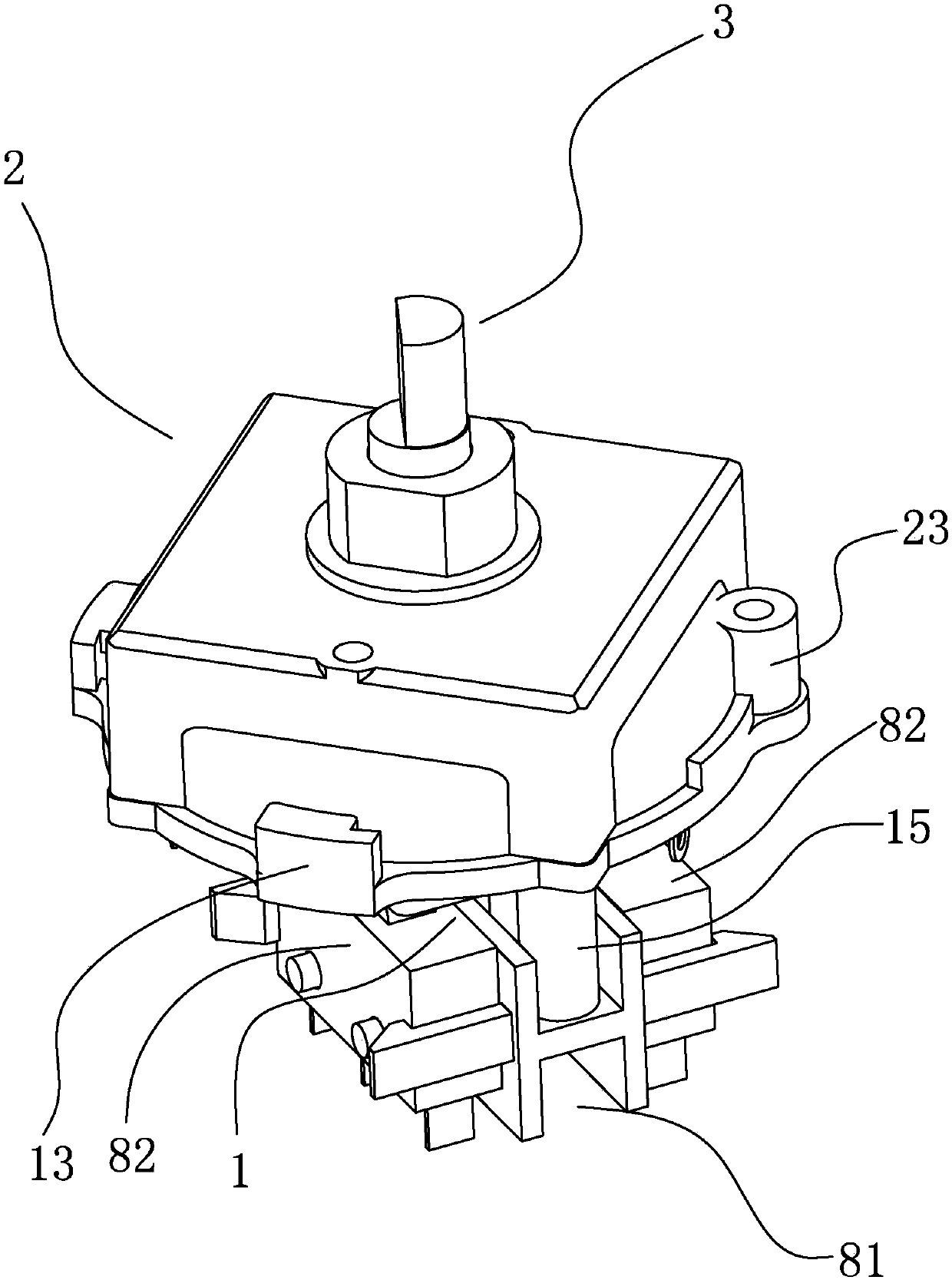

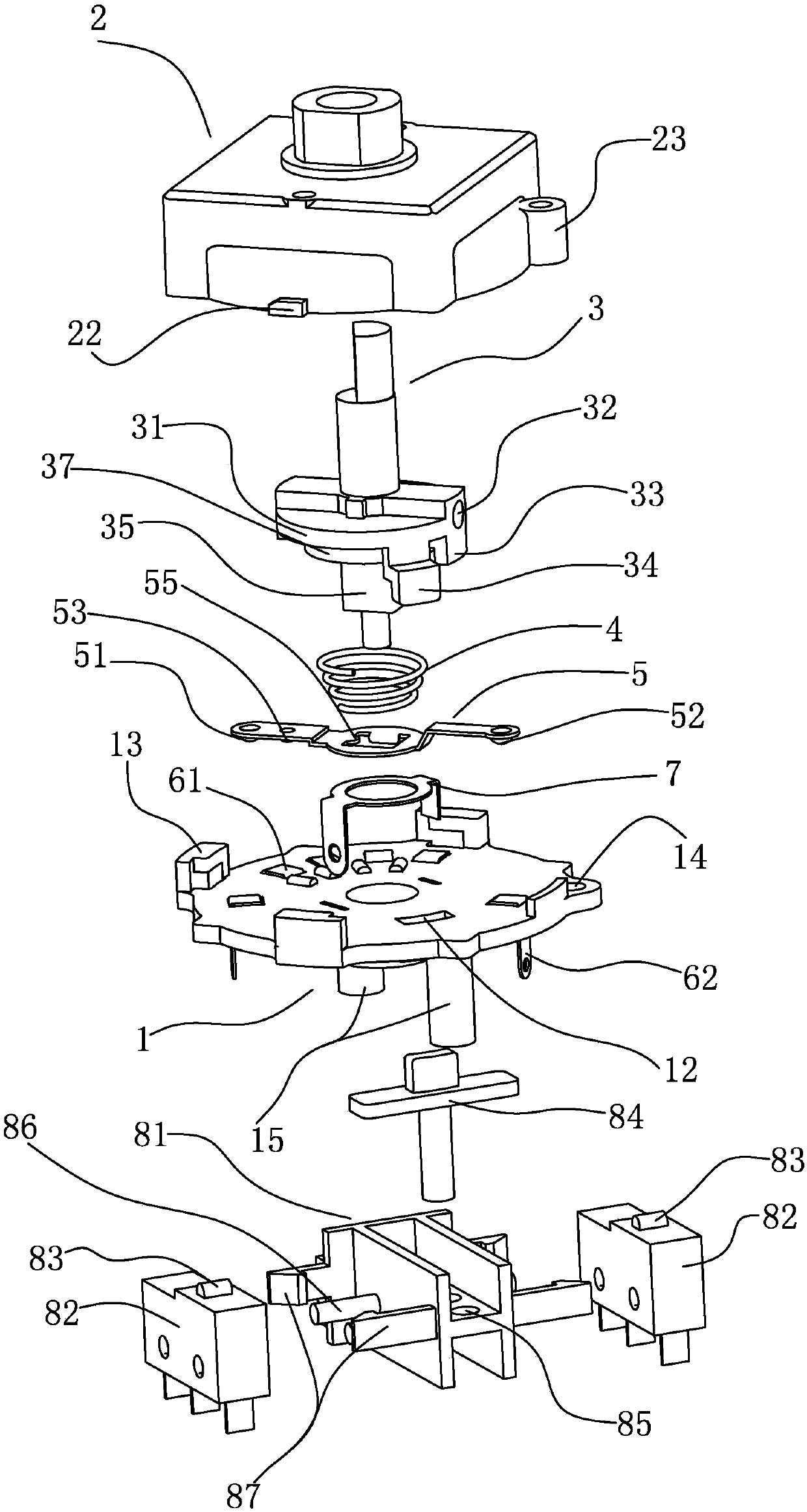

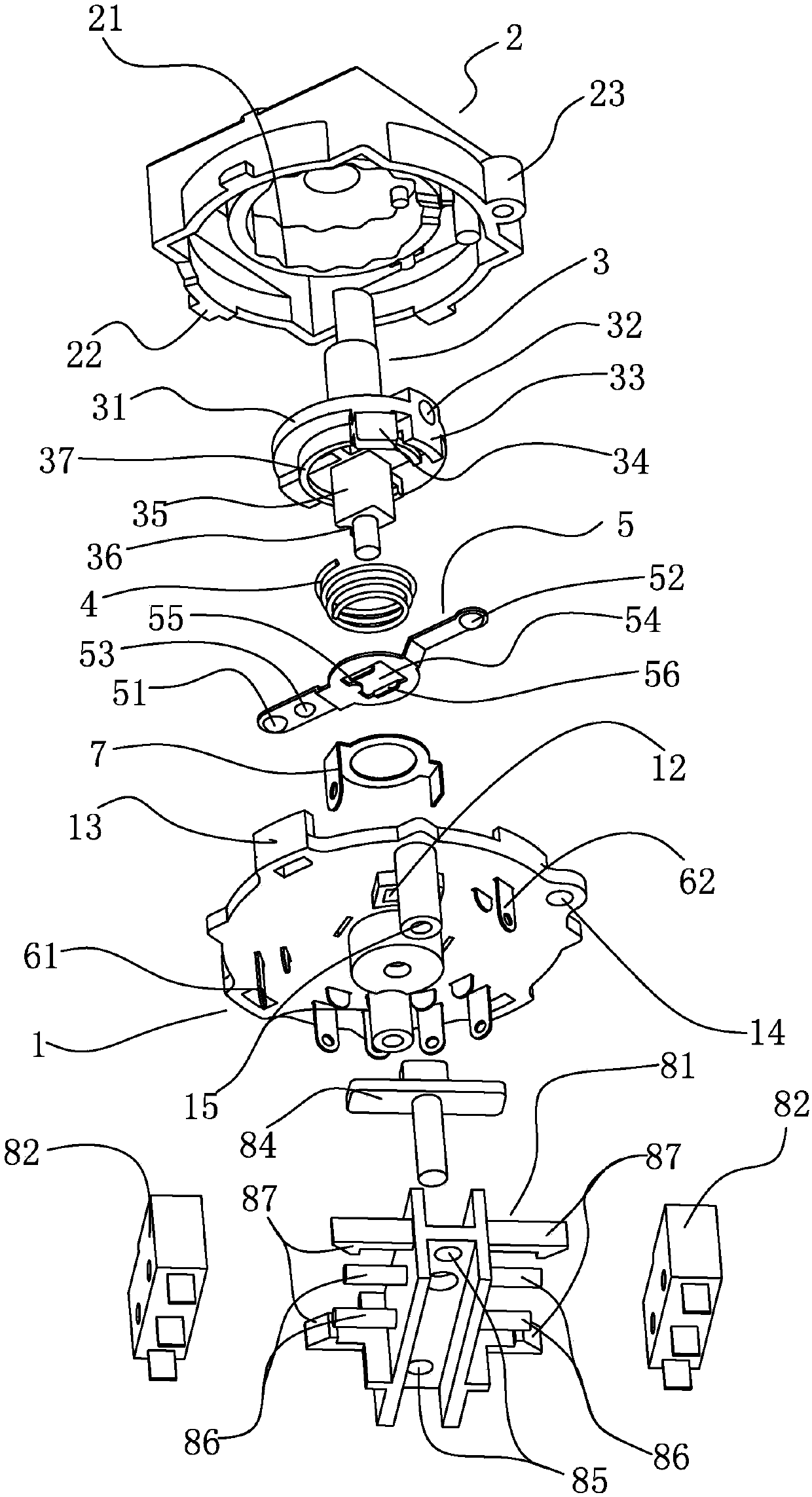

[0028] refer to Figure 1~3 , a motor rotary switch, including a chassis 1, a top cover 2 fixed on the chassis 1, a rotating shaft 3 rotatably arranged in the top cover 2 and / or chassis 1, and a rotation for positioning the rotation of the rotating shaft 3 Positioning device, the rotating shaft 3 is sequentially set with a switch spring 4 and a moving contact piece 5, the switching spring 4 and the moving contact piece 5 are in conflict, the chassis 1 is provided with more than one static contact piece, and the moving contact piece 5 is driven by the rotating shaft 3 Rotate and contact with each static contact respectively, the movable contact 5 is electrically connected with the central contact 7, the movable contact 5 includes a rotary contact 51 and a jogging contact 52, and the static contact includes a contact with the rotary contact 51 respectively. The rotary contact piece 61 and the jog contact piece 62 arranged with the jog contact 52, the bottom of the rotary contact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com