Lined clothes overlap vent structure

A technology for clothing and folding doors, applied in the field of clothing, can solve problems such as complicated operations, easy hair leakage at the opening and cutting of lining materials, deformation and tearing of slits, etc., to solve the problem of yarn direction and prevent slits and tears , The effect of simplifying the sewing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

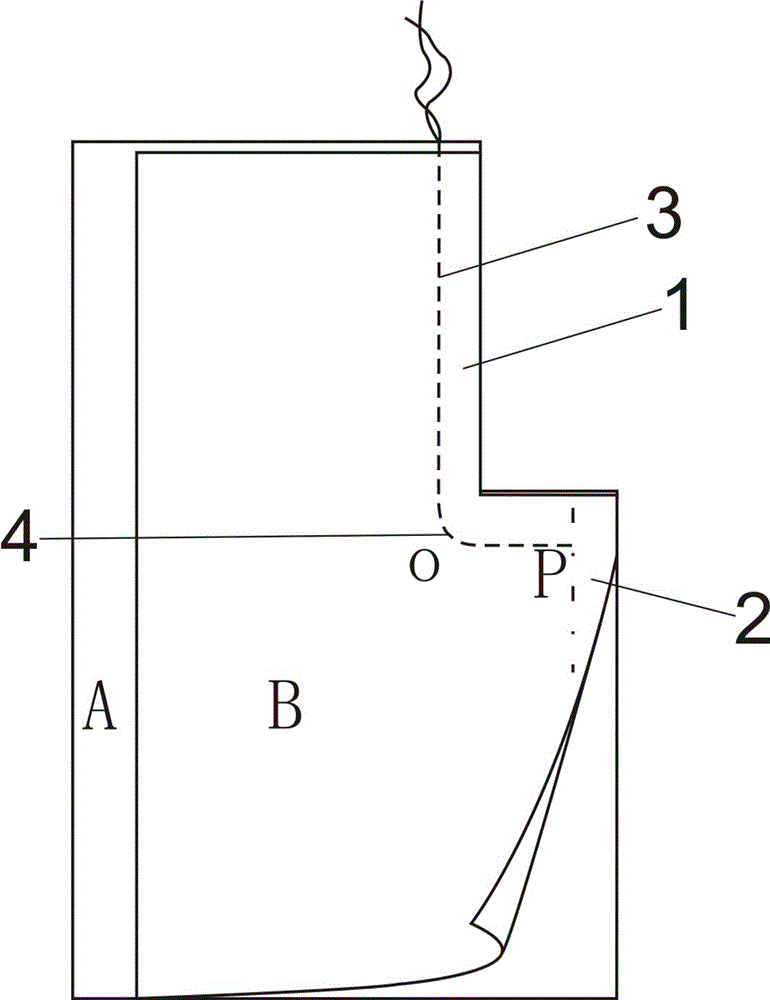

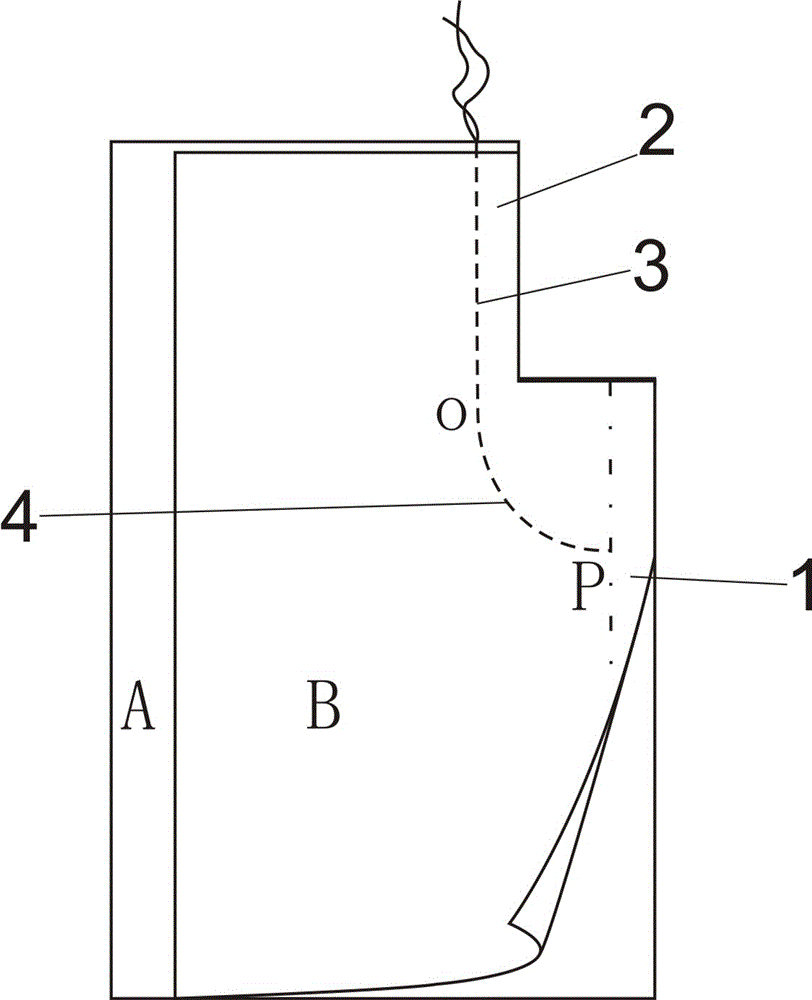

[0025] attached figure 1 , 2 It is a schematic diagram of the garment surface structure of the prior art, with Figure 5 , 6 It is a schematic diagram of the unfolded structure of the garment sheet in the prior art.

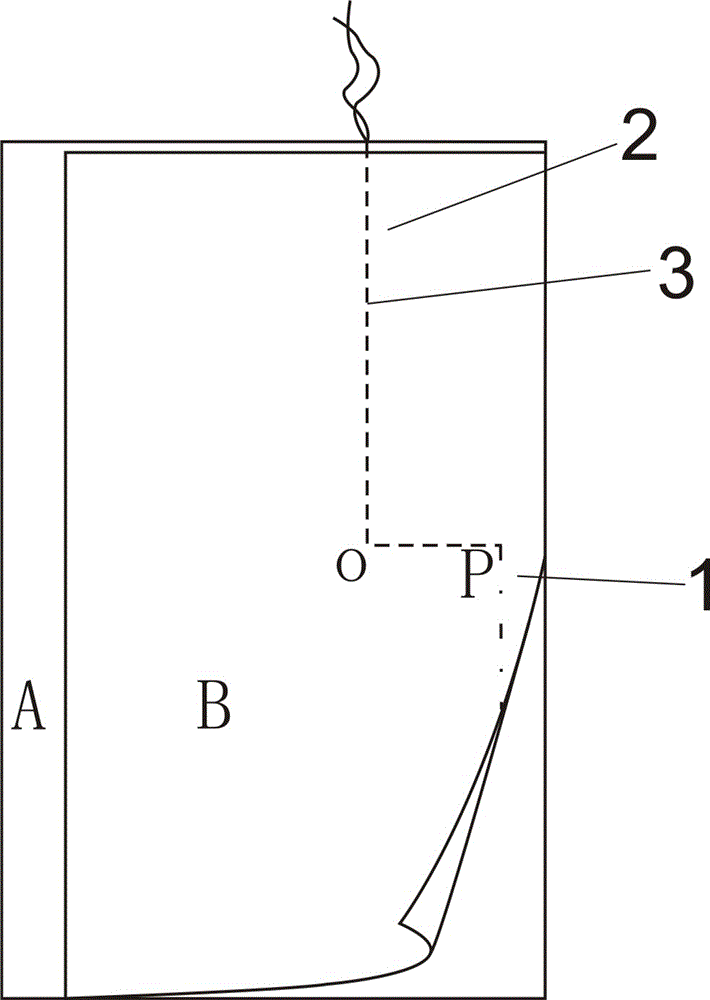

[0026] See attached image 3 , 4 , 7, a kind of lining garment folding door slit structure that the present invention relates to, comprises left garment side A, right garment side B, and corresponding left garment side A', right garment side B'. The seam allowance 1 at the slit of the left garment side A and the right garment side B is 1-2cm, the seam allowance 2 above the slit is flush with the seam allowance 1 at the lower side slit, and the width is equal to the difference between the width of the slit and the width of the slit seam And, the left garment side A and the right garment side B are sewed on the outside along the seam allowan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com