Marking device for allowance lines and inspection lines in hull construction

A line marking device and inspection line technology, which is applied in ship construction, ship parts, transportation and packaging, etc., can solve the problems of costing line marking workers and heavy workload, and achieve the effect of improving competitiveness and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

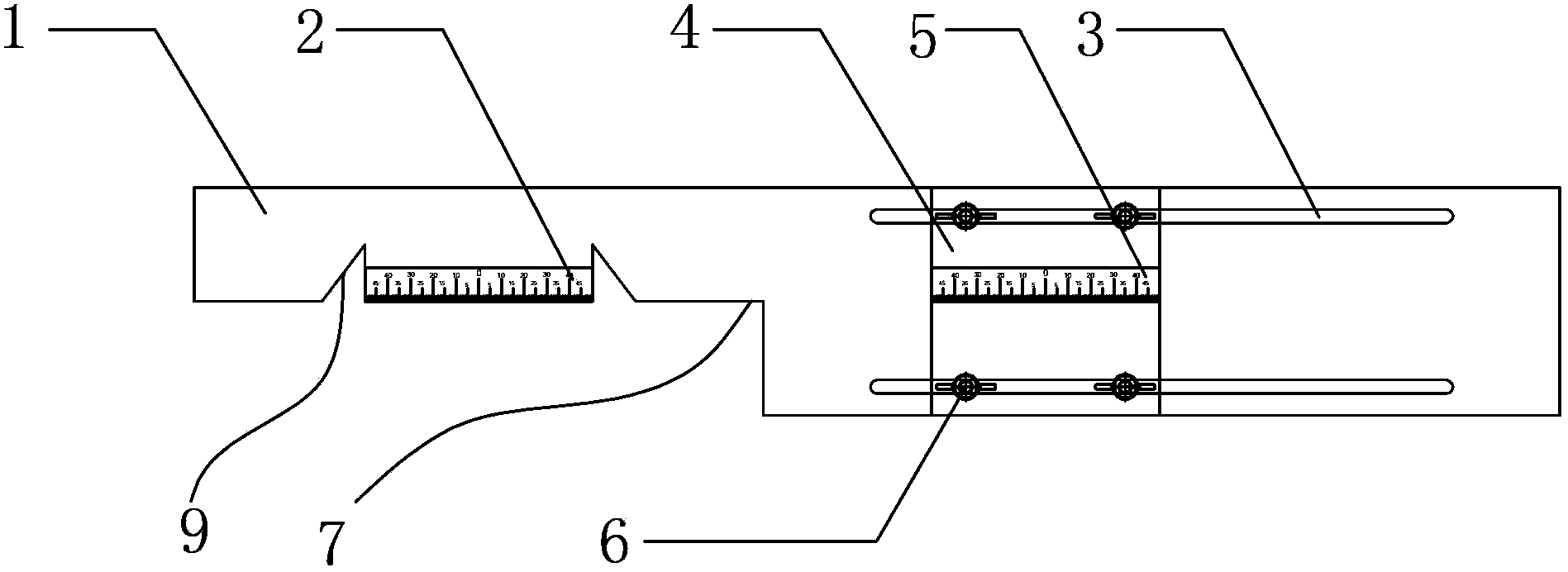

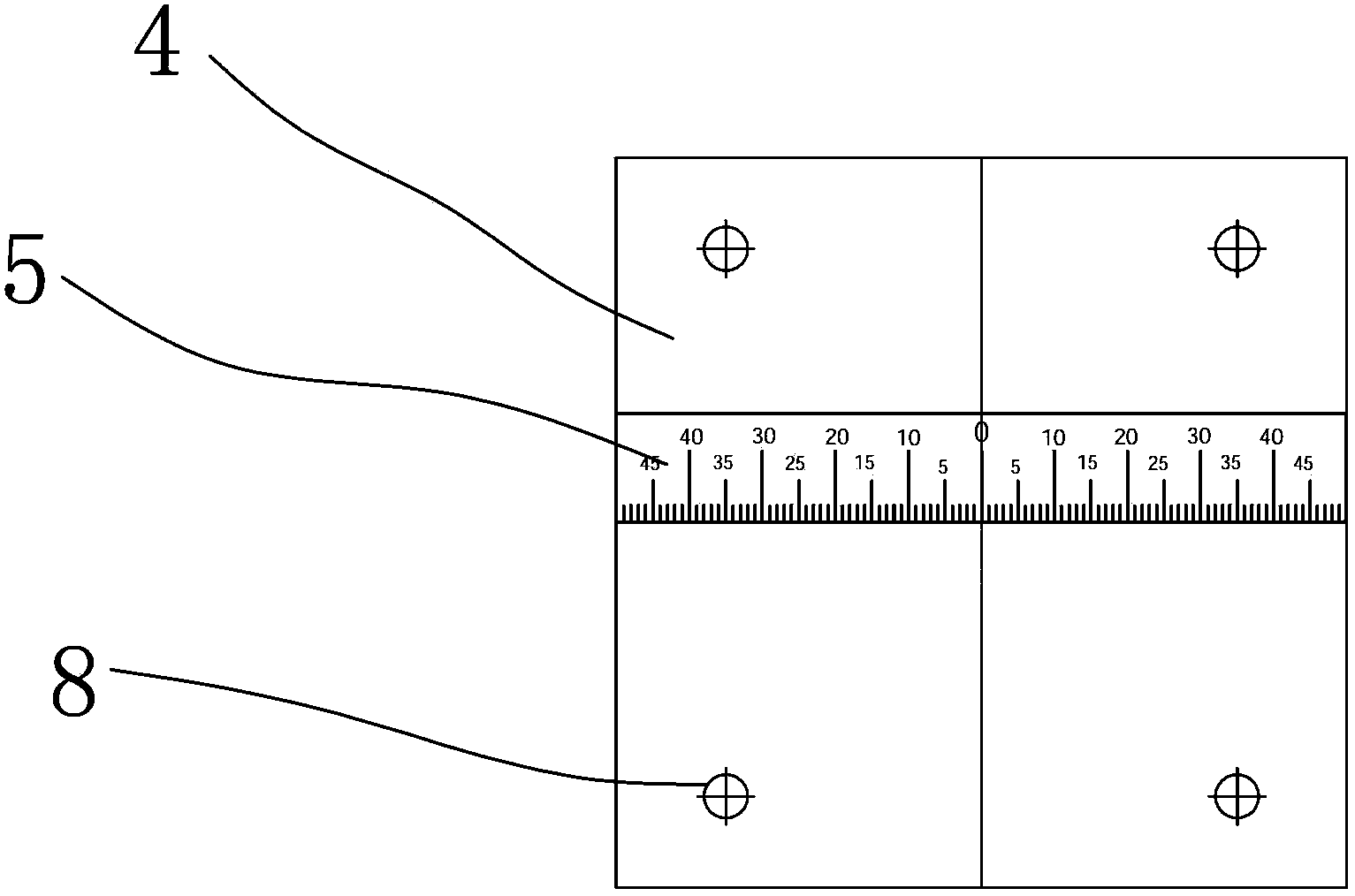

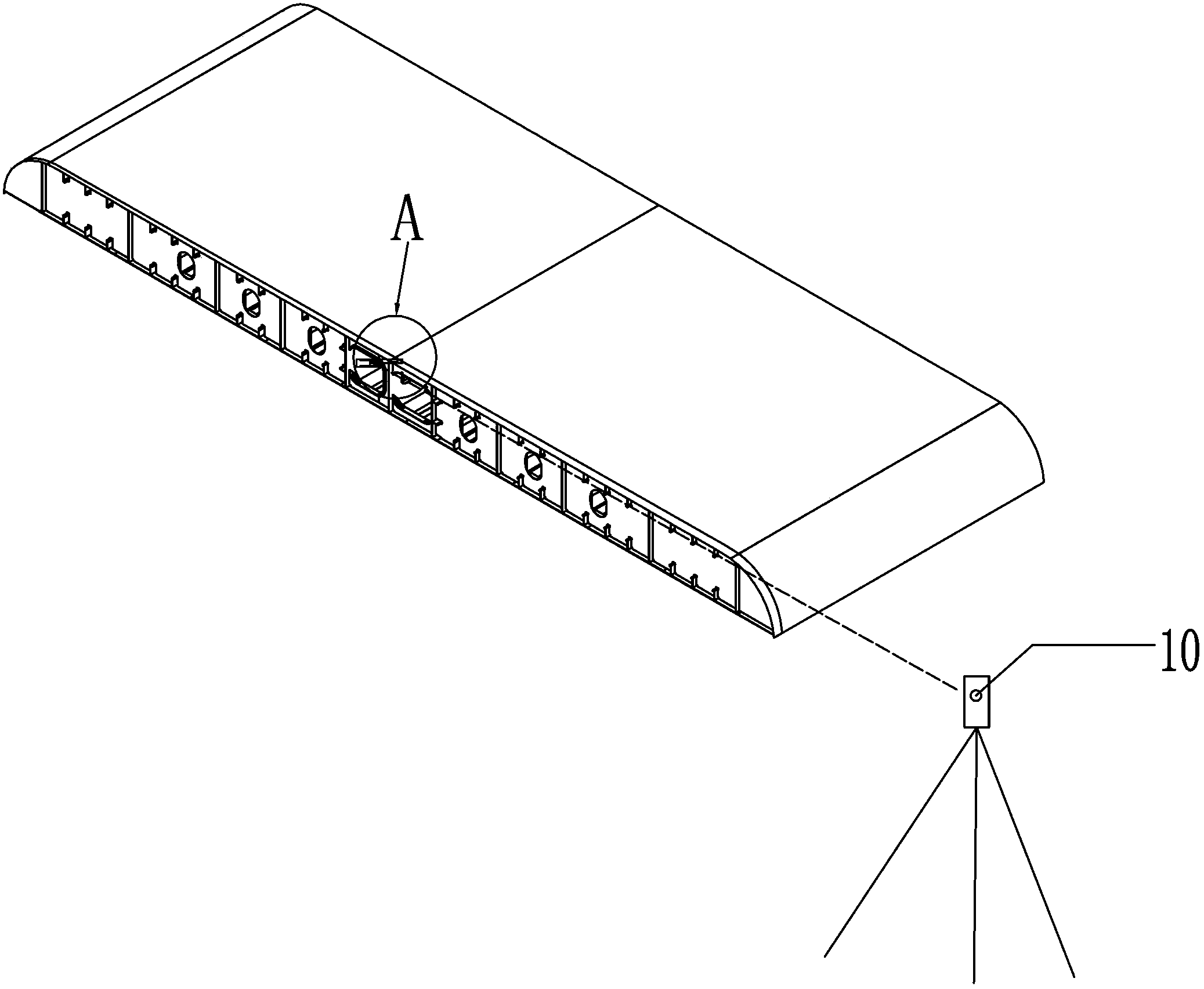

[0015] refer to figure 1 with figure 2 , the margin line and inspection line marking device used for hull construction, comprising a marking board 1, the surface of the marking board 1 is provided with a scale 2, the marking board of the marking board 1 The lower end surface of the stern is a right-angle protruding structure 7, which is used to align the joints of the straight sections of the hull; the surface of the right-angle protruding structure 7 is processed with two parallel chute 3. There is also a moving target plate 4 that can be horizontally translated with the chute 3 as a track. The four corners of the moving target plate 4 are processed with shaft holes 8, and the shaft holes 8 are perforated with holes for locking the moving target plate 4. Bolt assembly 6, after the bolts are loosely matched, the moving target plate 4 can slide freely and horizontally on the chute 3, and after the bolts are locked, the moving target plate 4 is locked on the chute 3; the surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com