Flat mop with water screw-out and spray functions

A functional, flat mopping technology, applied in the field of flat mopping with water wringing and water spraying functions, can solve the problems of increasing the mop space area, poor wringing effect, unreasonable design, etc., to improve wringing efficiency, improve Wringing effect, well-designed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

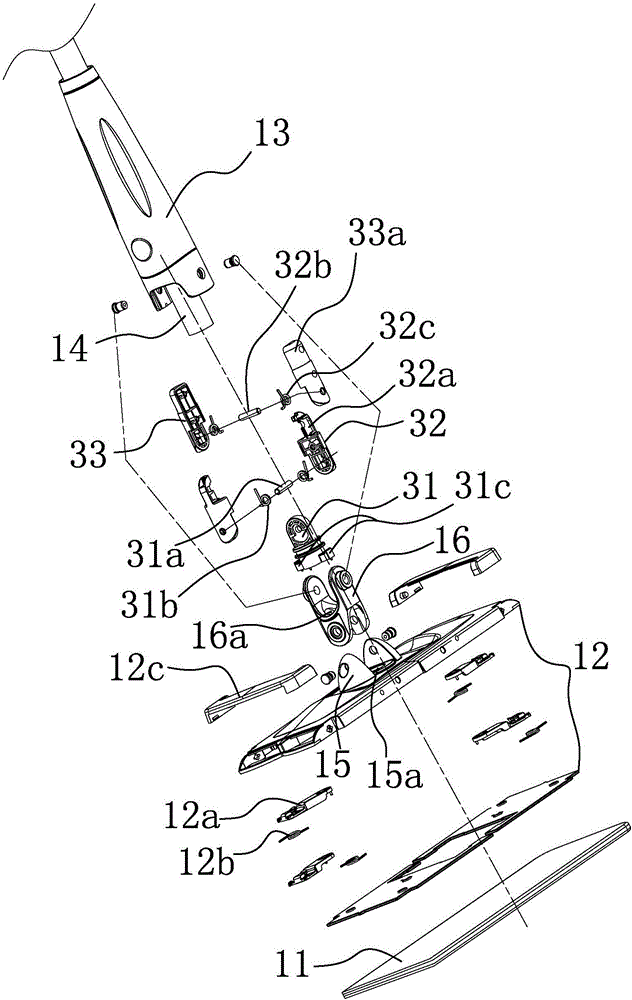

[0033] The following are specific embodiments of the invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

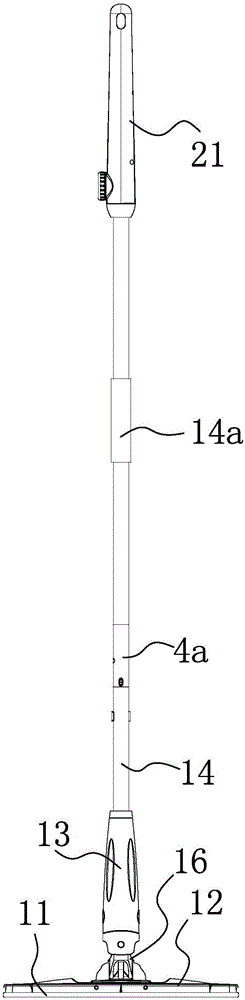

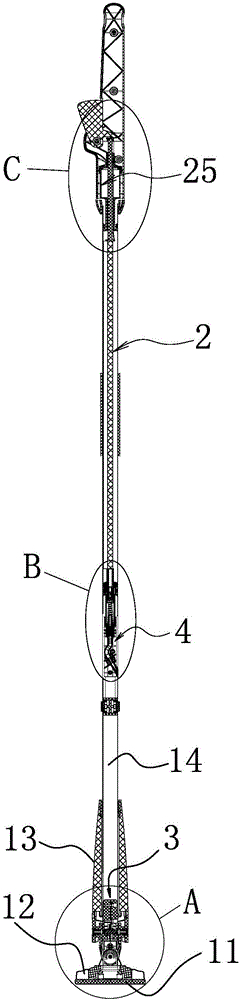

[0034] Such as Figure 1-2 As shown, the flat mop with water twisting and water spraying functions includes a mop 11 and a foldable plate cleaning part 12 at both ends. The lower surface of the panel is provided with a panel bottom cover, and the sub-panel can be folded inward under the action of external force.

[0035] The two ends of the mop 11 are connected to the two ends of the plate-type cleaning part 12 one by one, and the middle part of the plate-type cleaning part 12 is hinged with a water-screwing handle 13, and the water-screwing handle 13 is provided with a handle that can move axially along the water-screwing handle 13. The holding pipe 14 is provided with a sheath 14a in the middle of the holding pipe 14. Under the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com