multi-function flat drag

A multi-functional, flat mopping technology, which is applied in the field of multi-functional flat mopping, can solve the problems of cumbersome hinges between the mop handle and the mop, poor wringing effect, and stuck operation, so as to improve wringing efficiency and improve wringing efficiency. Dry effect, easy to disassemble and assemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

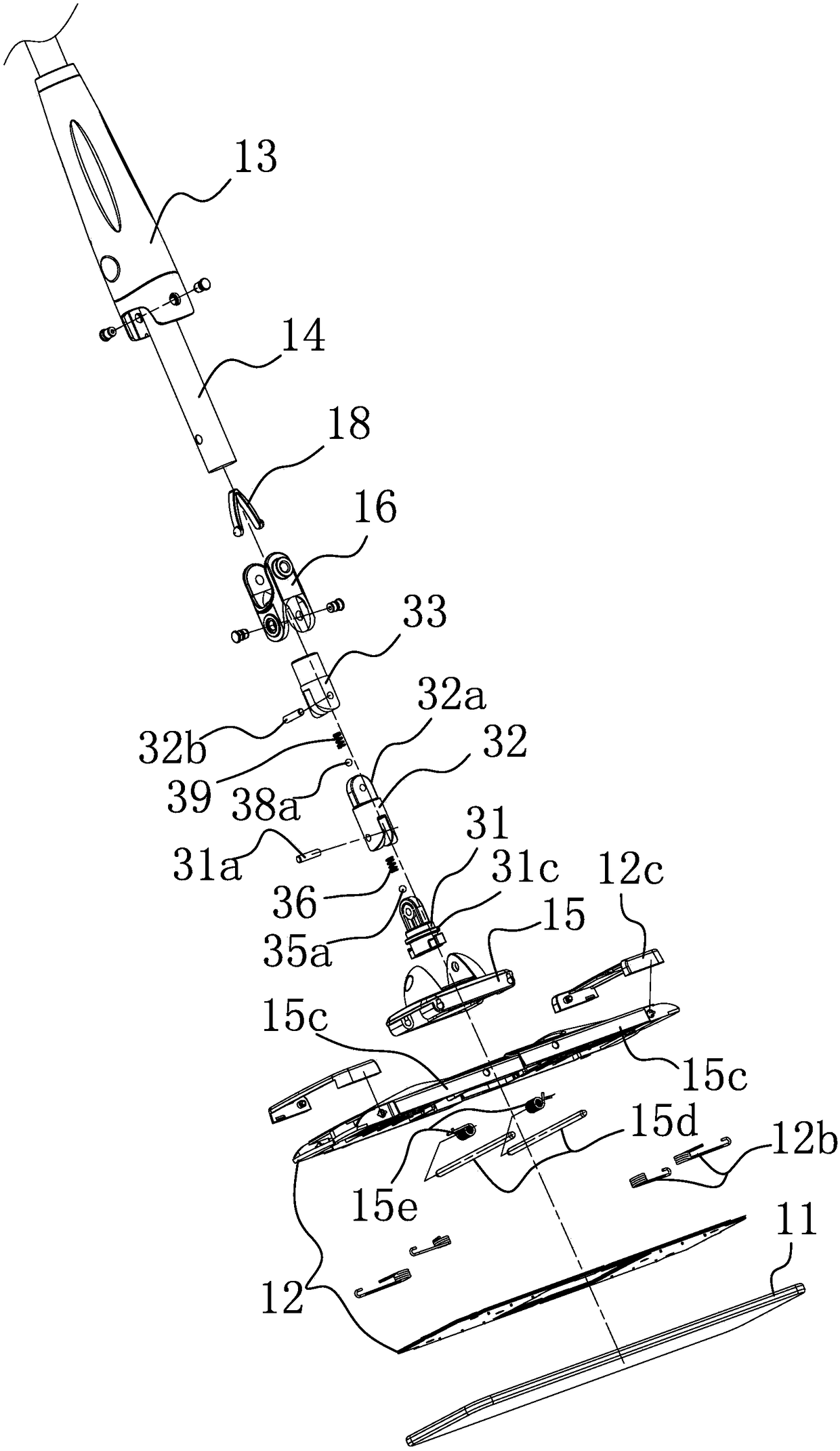

[0037] The following are specific embodiments of the invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

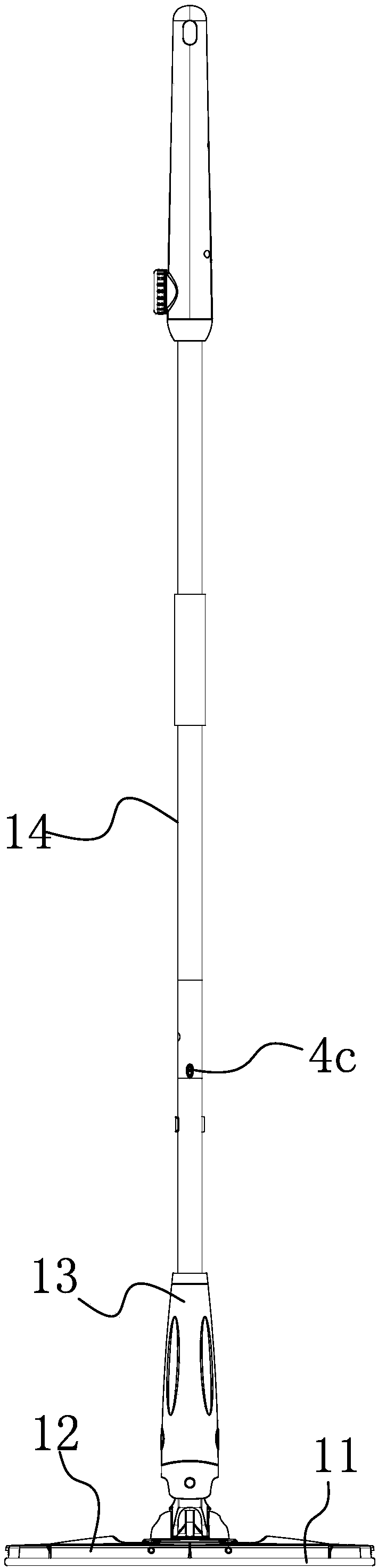

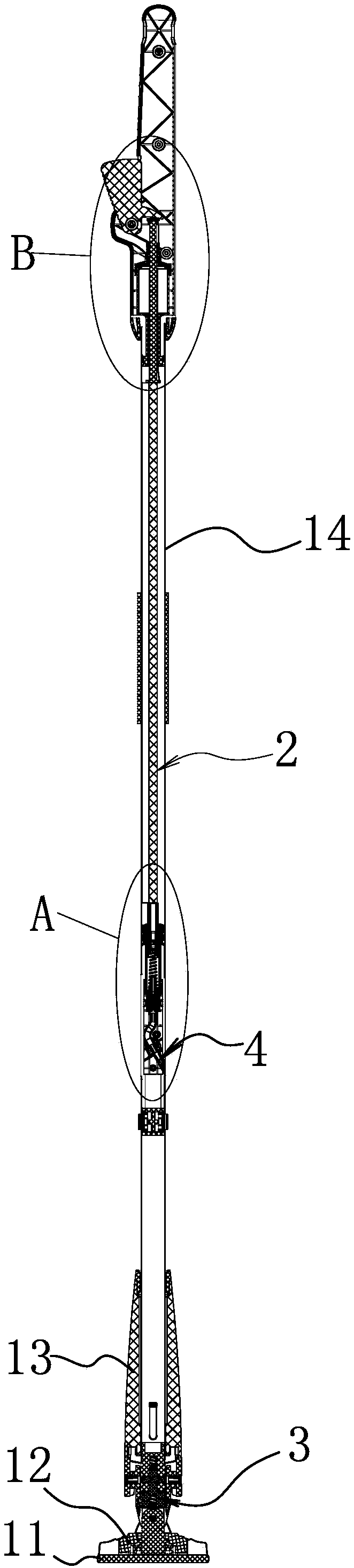

[0038] Such as Figure 1-2 As shown, the multi-functional flat mop includes a mop 11 and a plate-type cleaning component 12 that can be folded at both ends. The plate-type cleaning component 12 includes a connecting piece 15 having a first through hole 15a. The panel 15c that is turned over is connected between the connector 15 and the panel by the panel pin shaft 15d, and the panel torsion spring 15e is sleeved on the panel pin shaft, and the panel torsion spring can force the panel to reset after being turned over, that is, the mop can be stretched. flat. The two ends of the mop 11 are connected to the two ends of the plate type cleaning part 12 one by one, and the two ends of the mop 11 are respectively provided with the mop b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com