Wearproof yarn

A technology of yarn and core yarn, which is applied in the field of yarn production, can solve the problems that cannot meet the requirements of yarn use, yarn tensile and abrasion resistance is not particularly good, and does not have a core yarn, etc., to achieve effective Anti-abrasion and tensile, increased abrasion resistance, increased tensile and abrasion resistance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

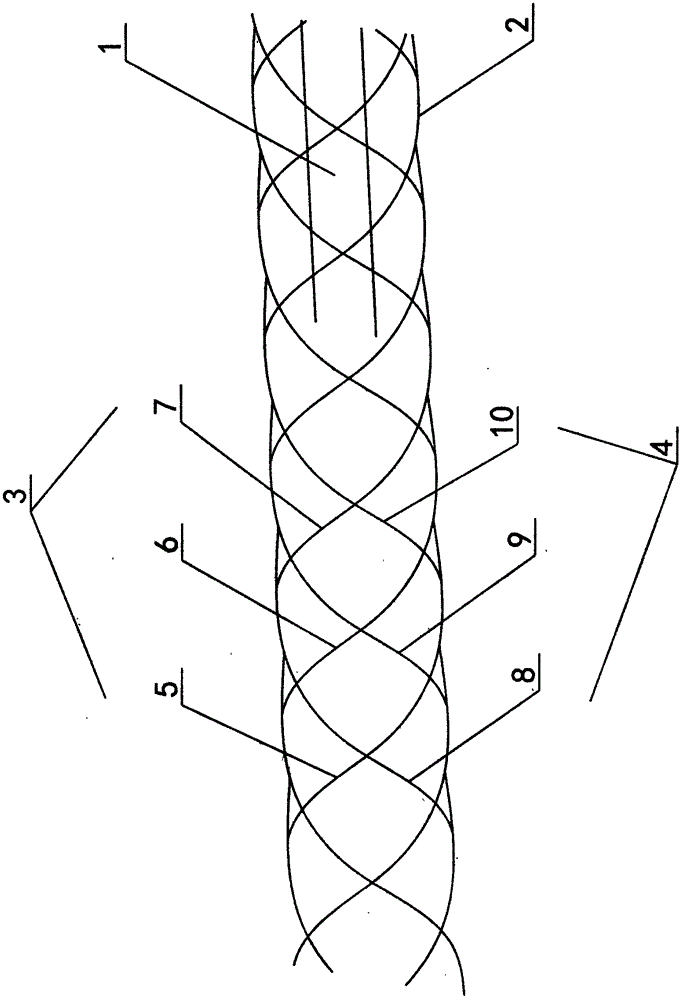

[0017] As an embodiment of the wear-resistant yarn of the present invention, such as figure 1 As shown, it includes a core yarn 1 and a wrapping yarn 2, the core yarn 1 is a monofilament yarn, the wrapping yarn 2 includes a forward wrapping yarn 3 and a reverse wrapping yarn 4, and the forward wrapping yarn 3 includes The first forward monofilament yarn 5, the second forward monofilament yarn 6 and the third forward monofilament yarn 7, the reverse wrapping yarn 4 includes the first reverse monofilament yarn 8, the second reverse monofilament yarn yarn 9 and the third reverse monofilament yarn 10, the first forward monofilament yarn 5, the second forward monofilament yarn 6 and the third forward monofilament yarn 7 are wound in parallel on the outside of the core yarn 1, The first reverse monofilament yarn 8, the second reverse monofilament yarn 9 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com