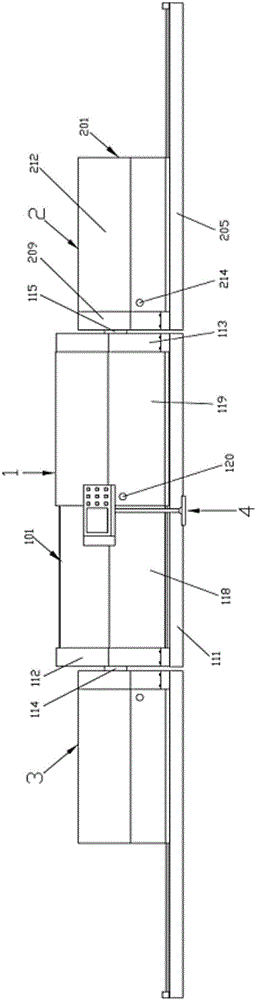

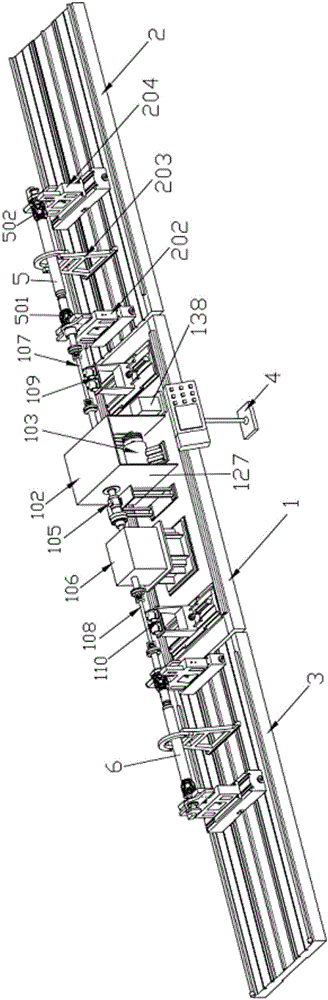

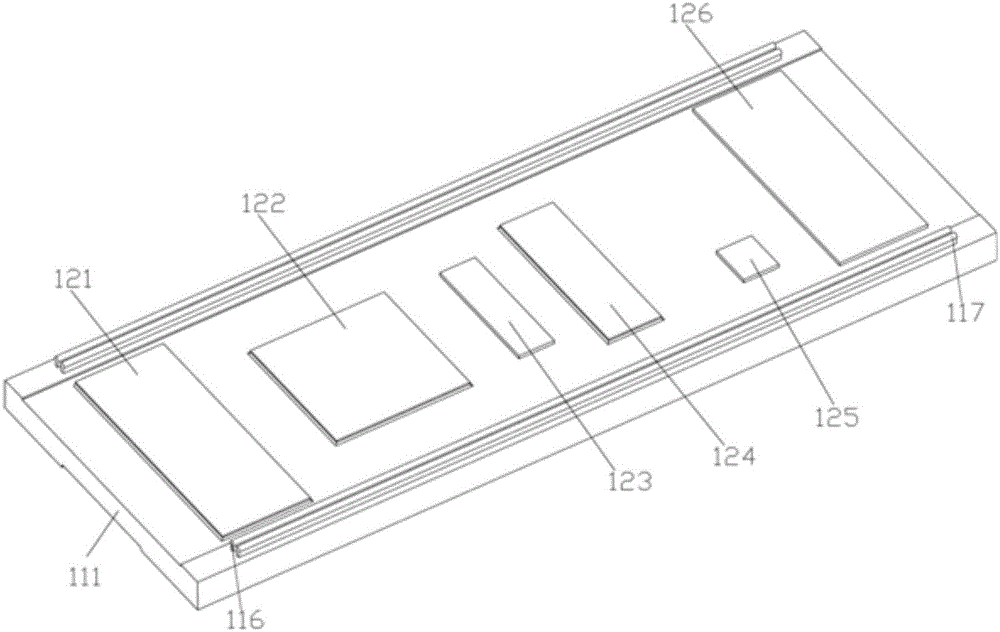

Comparison test device capable of detecting vibration and simulation real-time conditions of automobile transmission shaft

A comparative test, drive shaft technology, applied in vibration testing, measuring devices, machine gear/transmission mechanism testing, etc., can solve problems such as unintuitive data, low factory efficiency, and time-consuming and labor-intensive drive shaft vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

test approach 2

[0084] Test scheme 2: This scheme is mainly determined according to the actual situation of the factory's production of drive shafts. The details are the same as the experimental scheme 1, the difference is that this scheme is to improve efficiency and reduce cost. That is, the comparison test device provided by the present invention, which can detect the vibration of the transmission shaft of an automobile and simulate the actual situation, can detect one transmission shaft, and can also detect two transmission shafts at the same time. What needs to be considered is that when a drive shaft needs to be tested, the transmission device 106 is turned off, so that the third test stand 3 stops working, so as to save energy. This scheme realizes simultaneous detection of whether the two transmission shafts meet the factory requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com