Electric connector

An electrical connector and bonding technology, which is applied in the field of holding structures for fixing conductive terminals, can solve the problems of electrical connector safety hazards, plastics are easy to melt, and temperature rises, and achieve the effect of avoiding the risk of melting plastics and stabilizing the fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

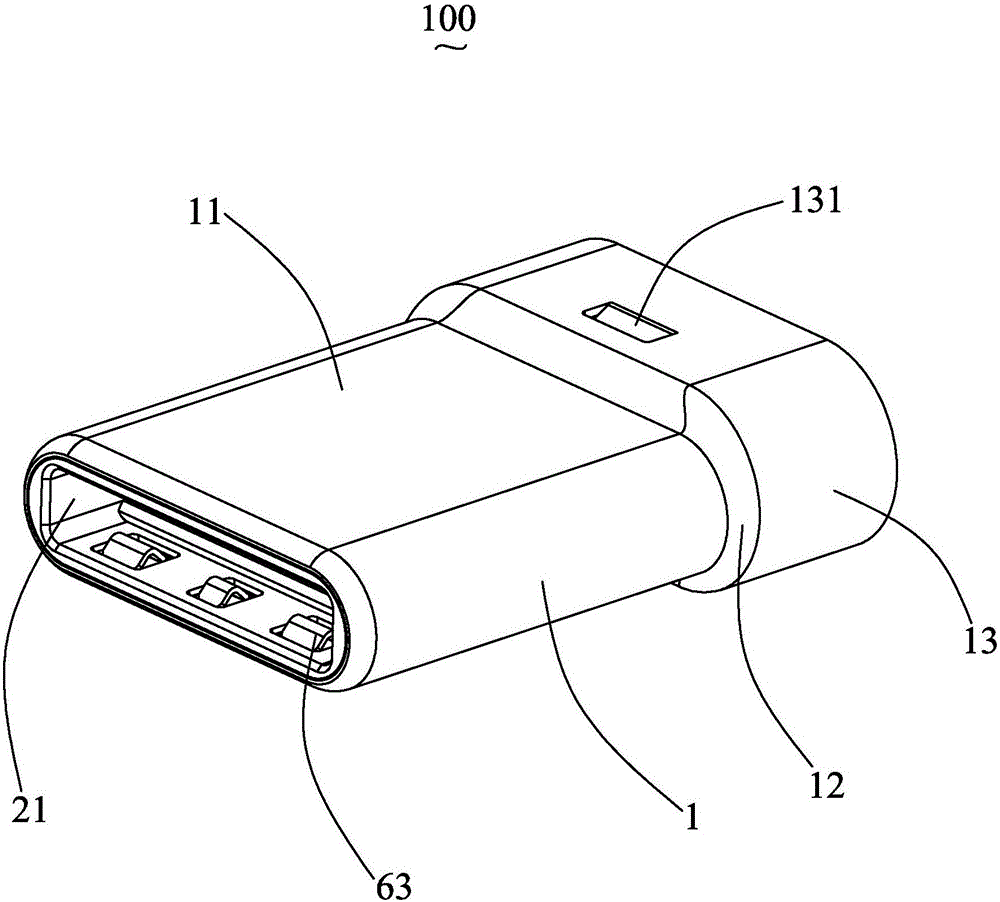

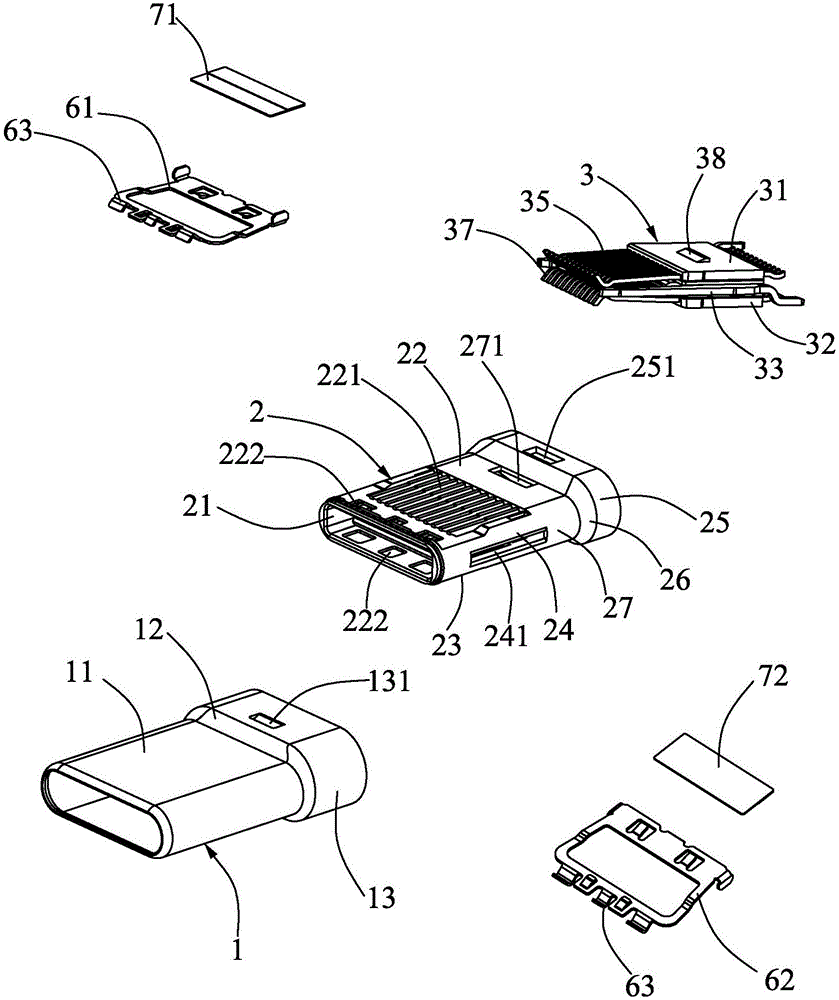

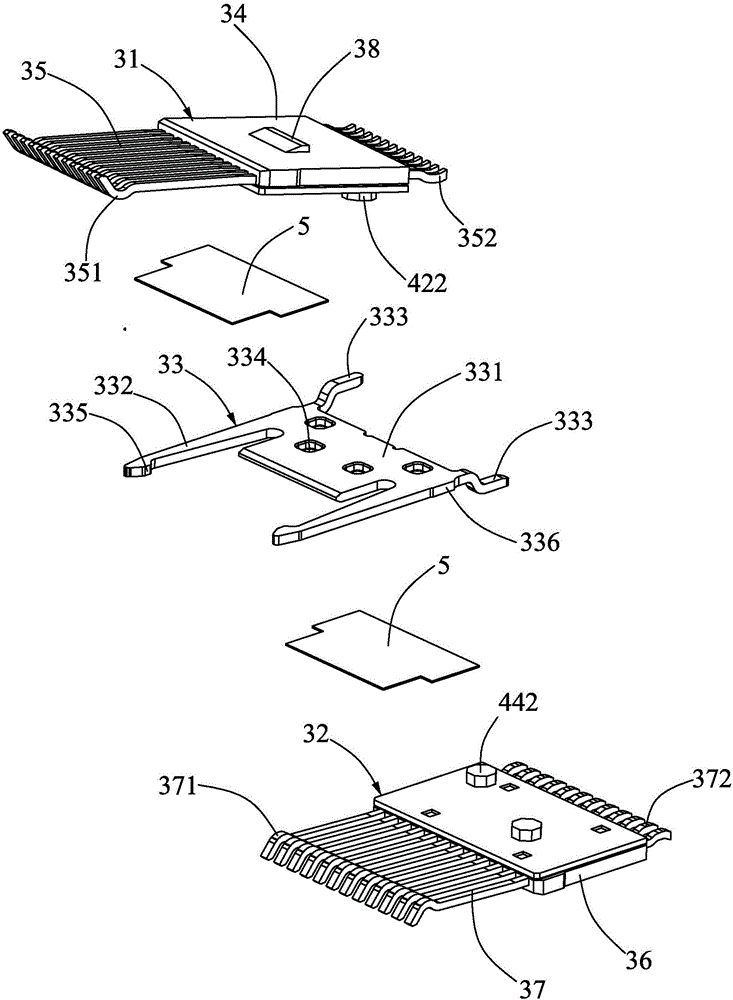

[0025] Such as Figure 1 to Figure 5 As shown, it is an electrical connector 100 according to the present invention, which includes: a metal shell 1 , an insulating body 2 fixedly installed in the metal shell 1 , and a terminal module 3 installed in the insulating body 2 .

[0026] The insulating body 2 includes a docking cavity 21 penetrating in front and rear directions, and the docking cavity 21 is configured to allow a docking tongue (not shown) to be inserted in two opposite directions. The insulating body 2 includes a top wall 22 , a bottom wall 23 , and two side walls 24 . The accommodating cavity 21 is surrounded by the top wall 22 , the bottom wall 23 , and the two side walls 24 . The top wall 22 and the bottom wall 23 are respectively provided with a row of terminal slots 221 and a plurality of through holes 222 located in front of the row of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com