Method and device for the control and the management of the printing parameters of a flexographic printing machine

A technology for flexographic printing presses and control devices, which is applied to general parts of printing machinery, printing presses, rotary printing presses, etc., and can solve problems such as deformation, affecting printing quality, and incorrect printing pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

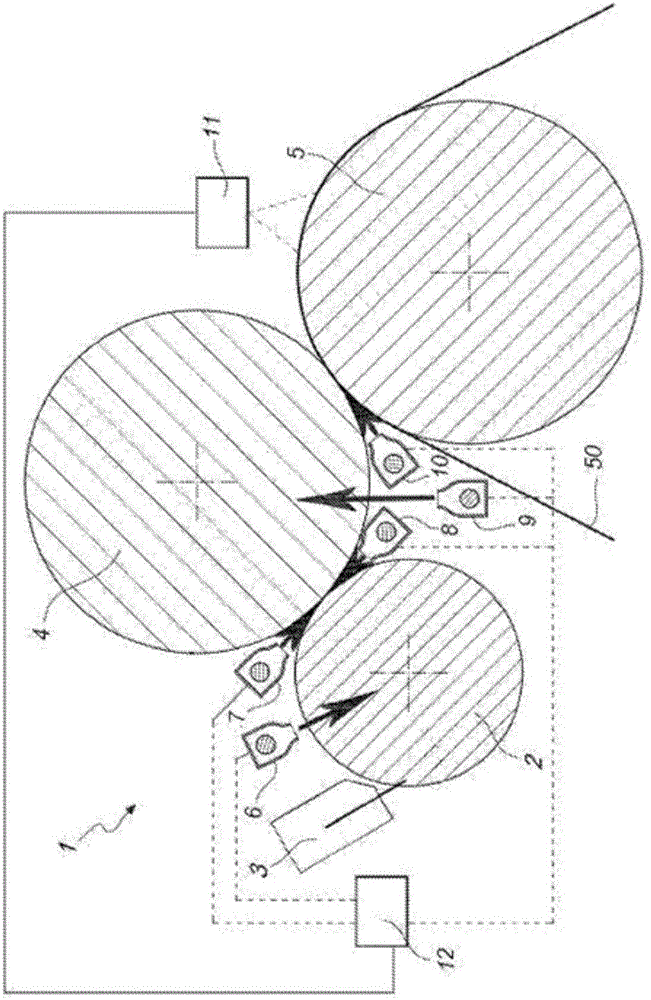

[0013] Referring to the above figures, the device according to the invention is generally indicated with the reference numeral 1 . The device is associated with a flexographic printing unit comprising a set of mutually tangential and counter-rotating rollers that transfer the ink film onto the printing medium, according to a construction known in the art. In particular, the printing unit comprises a first roller or anilox roller 2 associated with a doctor blade 3, from which ink is transferred to a second roller or printing roller (or printing sleeve 4) superior. Also associated with these two rollers is a third or counter roller 5 on which at least one printing medium is at least partially wound. Reference numeral 50 denotes a printing medium to which printing is applied and wound between the printing roller 4 and the reverse roller 5 .

[0014] Looking at the invention more closely, the device comprises at least one infrared emitting device in the form of an infrared emitt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com