A granular bed dust collector

A granular bed filter and dust collector technology, which is applied in the direction of dispersed particle separation, chemical instruments and methods, combined devices, etc., can solve the problems of increased pressure drop, unsatisfactory filtering and dust removal effect, and increased cost, so as to reduce the burden of filtration, Good filter and dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

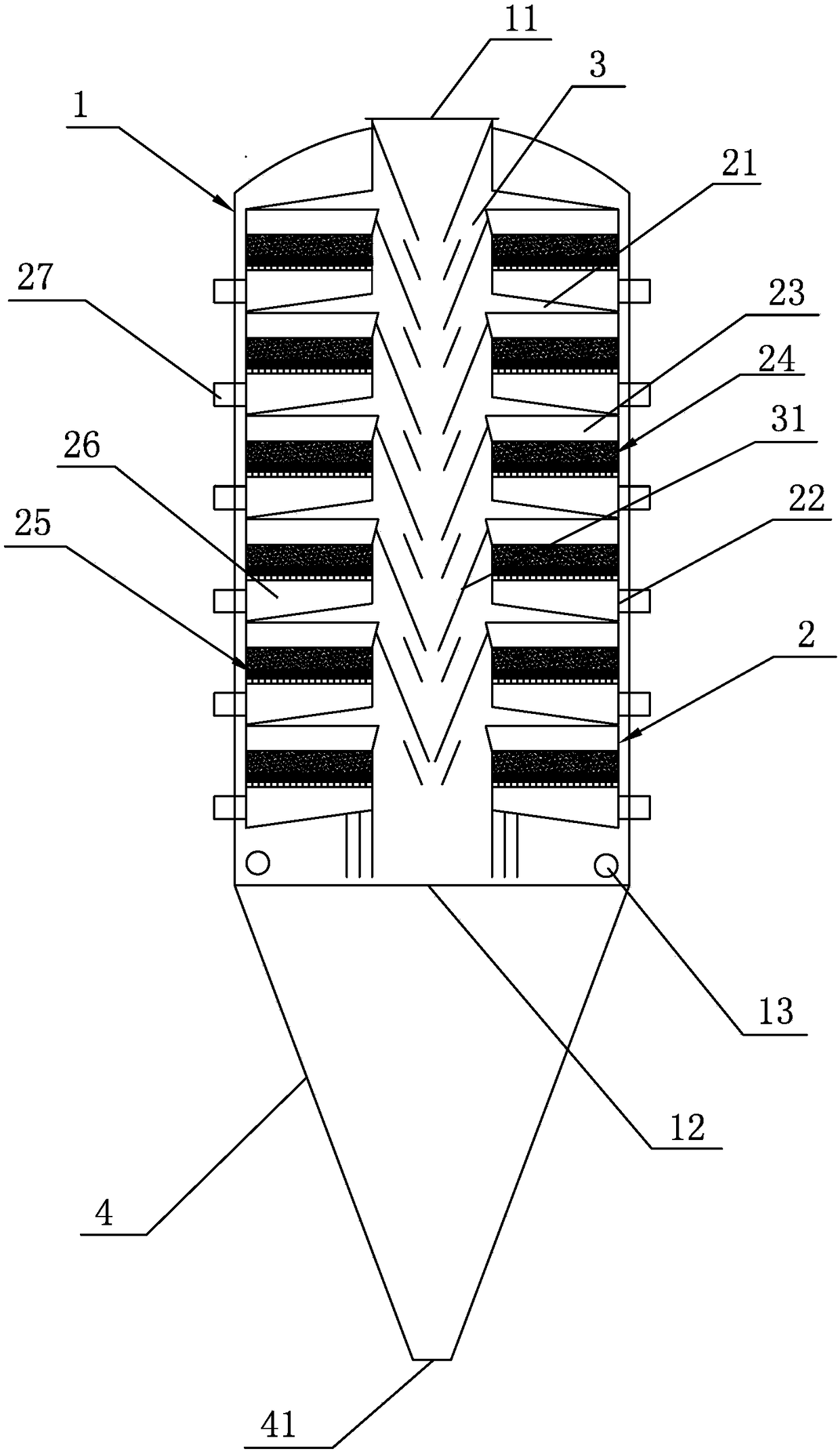

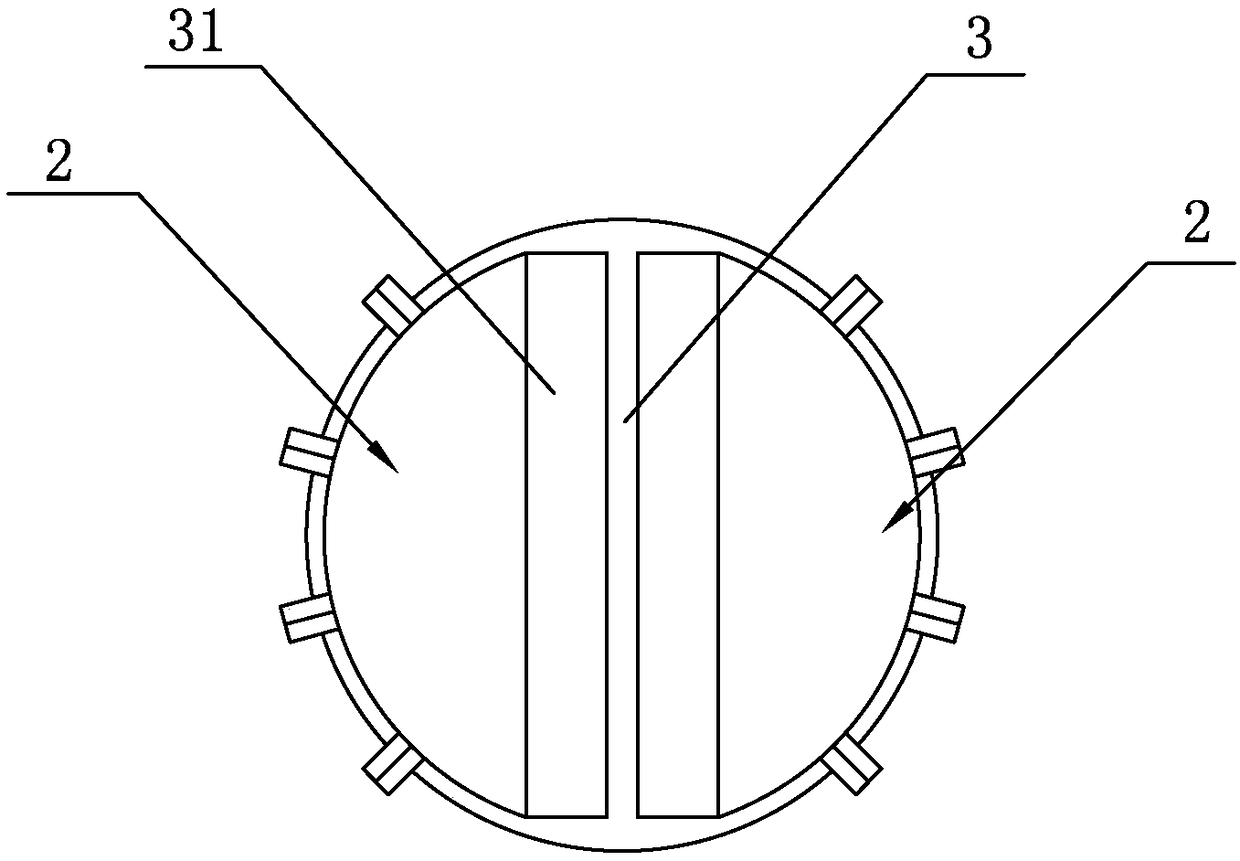

[0032] A kind of granular bed deduster that present embodiment proposes, such as Figure 1a As shown, it includes an outer shell 1 with a circular cross section and a six-layer particle bed filter arranged vertically inside the outer shell 1. The upper part of the outer shell 1 is provided with an upstream air intake pipe (not shown in the figure) outlet) connected to the dust-containing gas inlet 11, the lower part of the outer casing 1 is provided with a dust outlet 12, such as Figure 1b Each layer of the granular bed filter shown includes two filter units 2 with circular arc-shaped cross-sections. The two filter units 2 are symmetrically arranged on both sides of the outer casing 1, and between the opposite sides of the two symmetrically arranged filter units 2. There is a distance to form a separation space, the separation space and the inner wall of the outer shell 1 enclose a dust pre-separation chamber 3, the dust pre-separation chamber 3 is located between two symmetri...

Embodiment 2

[0037] A kind of granular bed deduster that present embodiment proposes, such as Figure 2a with Figure 2b As shown, it is the same as other parts of the granular bed dust collector of embodiment one, the difference is that: the cross section of the outer shell 1 is rectangular; the cross section of the filter unit 2 is also rectangular; each layer of granular bed filter includes Four filter units 2 with rectangular cross-sections, two filter units 2 are arranged on one side of the outer shell 1, and the other two filter units 2 are symmetrically arranged on the other side, between the opposite sides of the filter units 2 symmetrically arranged There is a distance to form a separation space, and the separation space and the inner wall of the outer casing 1 enclose the dust pre-separation chamber 3; each filter unit 2 at the bottom layer is no longer separated from filter units with a smaller filtration area.

Embodiment 3

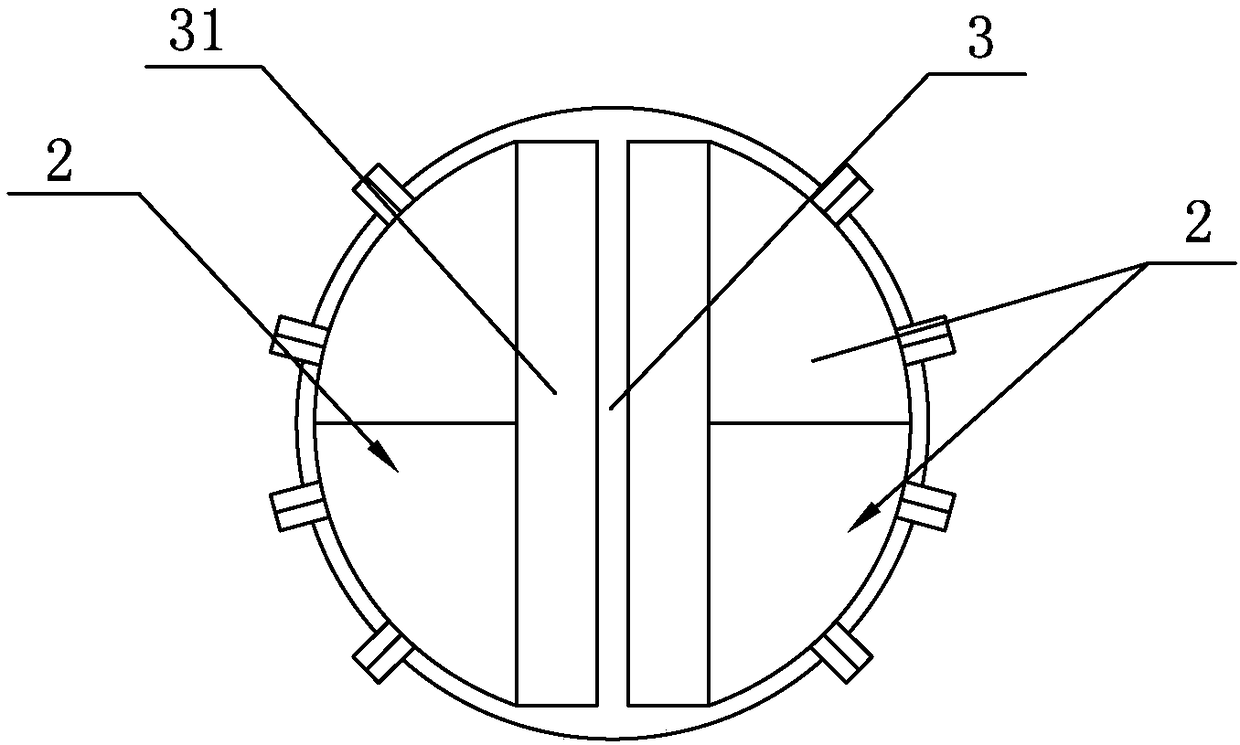

[0039] A kind of granular bed deduster that present embodiment proposes, such as Figure 3a As shown, it includes an outer casing 1 with a circular cross-section and a six-layer particle bed filter arranged vertically inside the outer casing 1. The upper part of the outer casing 1 is provided with a dust-containing gas that communicates with the upstream air intake pipe. Inlet 11, the bottom of outer casing 1 is provided with dust outlet 12, as Figure 3b Each layer of granular bed filter shown includes a filter unit 2 with a semicircular cross section. The other side of the outer casing 1 is surrounded by a dust pre-separation chamber 3, which is located on one side of the filter unit 2, and each filter unit 2 has an independent dust-containing air vent 21 and an independent clean air vent 22 , the entrance of the dust pre-separation chamber 3 communicates with the dust-containing gas inlet 11, the outlet of the dust pre-separation chamber 3 communicates with the dust discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com