Mechanical submerged arc furnace dust removal device

A technology of dust removal device and submerged arc furnace, which is applied to furnaces, waste heat treatment, furnace components, etc., can solve problems such as poor dust removal effect, and achieve the effect of reducing filter burden and increasing service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

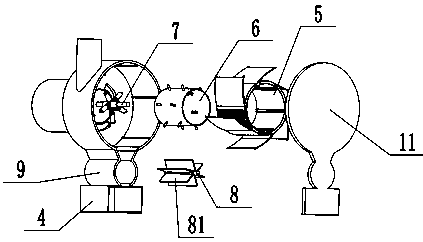

[0045] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

[0046] see Figure 1-Figure 8 It is a kind of mechanical dedusting device for submerged arc furnace in one embodiment, comprising:

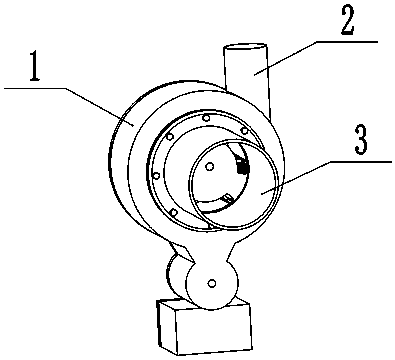

[0047] shell a1;

[0048] a cover a11 installed on one side of the housing a1;

[0049] The cover b12 is installed on the other side of the housing a1;

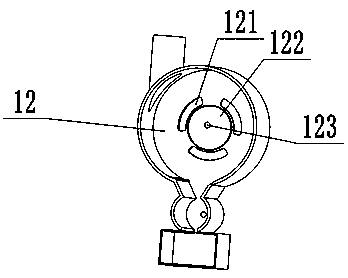

[0050] A round table 122, the round table 122 is installed on the cover b12;

[0051] A hole 121, the cover b12 is provided with a hole 121, and the hole 121 is located around the round platform 122;

[0052] An eccentric hole 123, the eccentric hole 123 is opened on the circular platform 122, and the center of the circle of the eccentric hole 123 and the circular platform 122 does not coincide;

[0053] The shaft a7 is installed in the eccentric hole 123; specifically, the shaft a7 is fixedly installed in the eccen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com