An automatic grading system and grading method for chicken carcass weight based on machine vision

A grading method and automatic grading technology, applied in sorting and other directions, can solve problems such as cross-infection of chicken carcasses, manual grading, secondary pollution of chicken carcasses, etc., and achieve the goal of avoiding pollution of chicken carcasses, accurate grading, and fast and efficient image processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with accompanying drawing of description, the present invention will be further described.

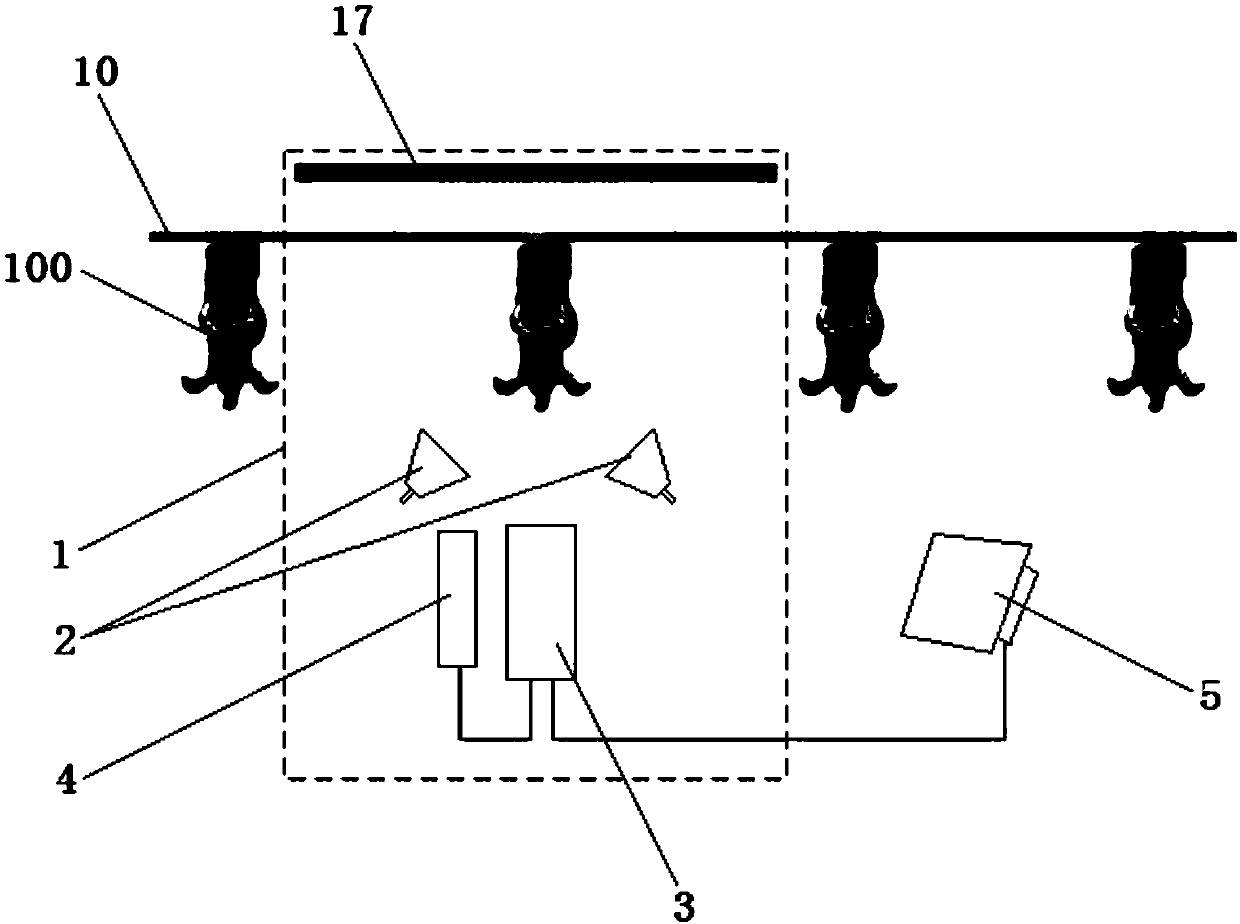

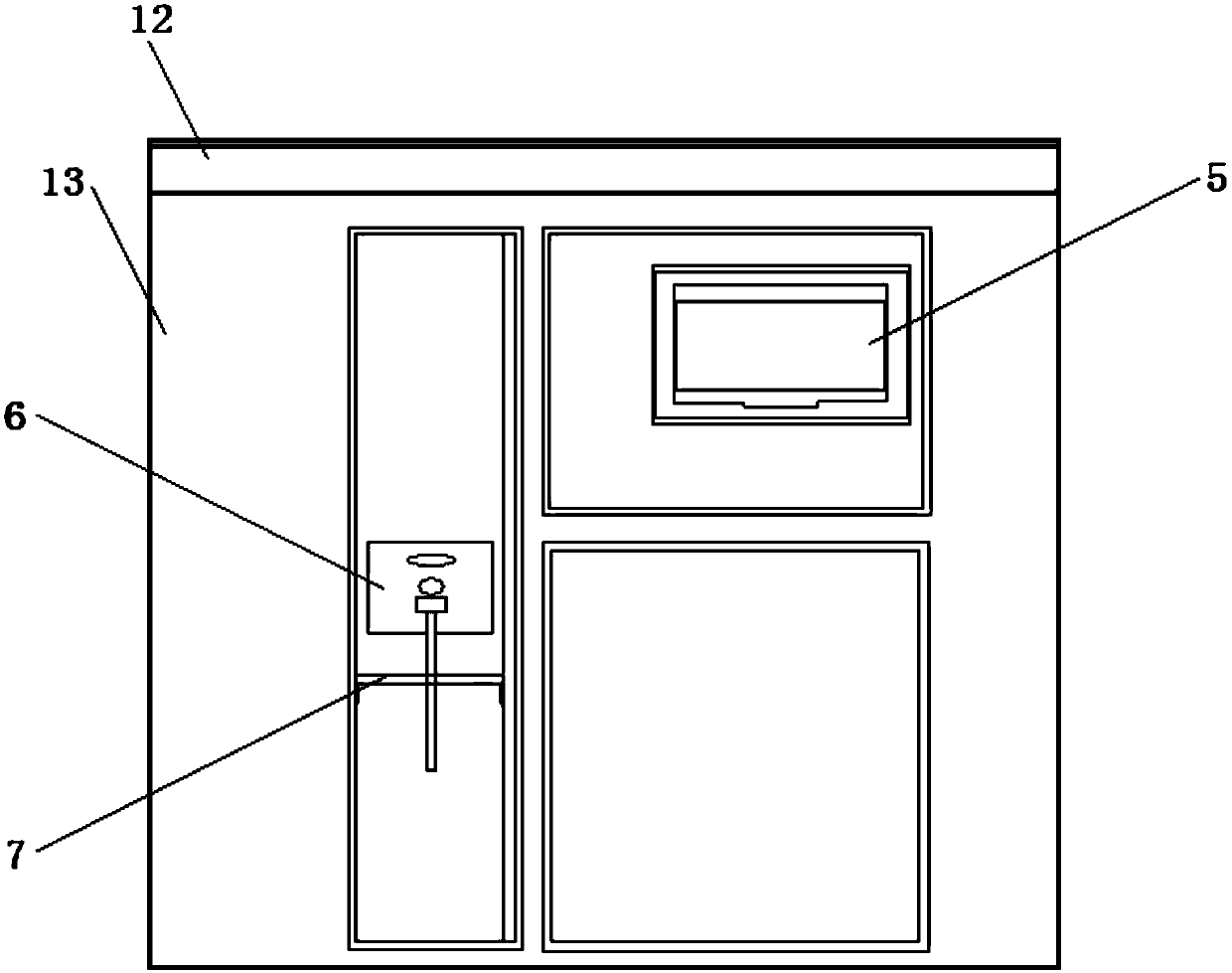

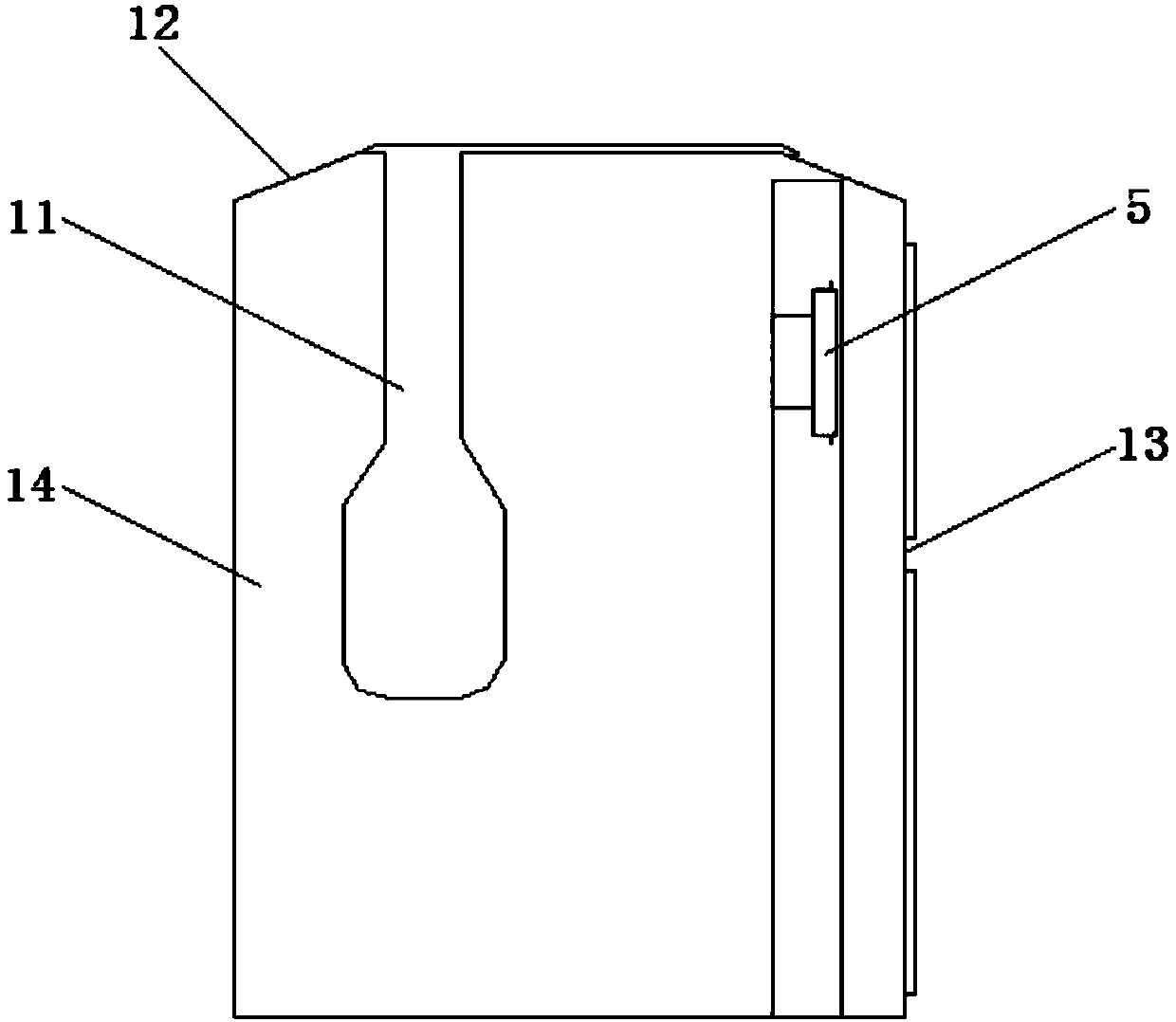

[0041] Such as Figure 1 to Figure 7Shown, a kind of chicken carcass weight automatic grading system based on machine vision, comprises the dark box 1 that is installed on the assembly line 10, is located in the light source 2 of dark box 1, industrial camera 3 and photoelectric switch sensor 4, and is externally arranged in dark box 1 The industrial computer 5; the assembly line 10 runs through the dark box 1, and the side wall of the dark box 1 is provided with a through hole 11, and the chicken carcasses 100 on the assembly line 10 all pass through the through hole 11 to enter the dark box 1 and are located at the shooting position for The industrial camera 3 collects the original image and passes through the camera obscura 1 through the assembly line 10 for grading. The setting of camera obscura 1 can eliminate the interference of external light to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com