Glass cover plate, manufacturing method thereof and mobile terminal

A production method and glass cover technology, which are applied in glass molding, glass manufacturing equipment, glass reshaping, etc., can solve the problems of people's high-quality appearance requirements, serious homogeneity, and lack of novelty, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

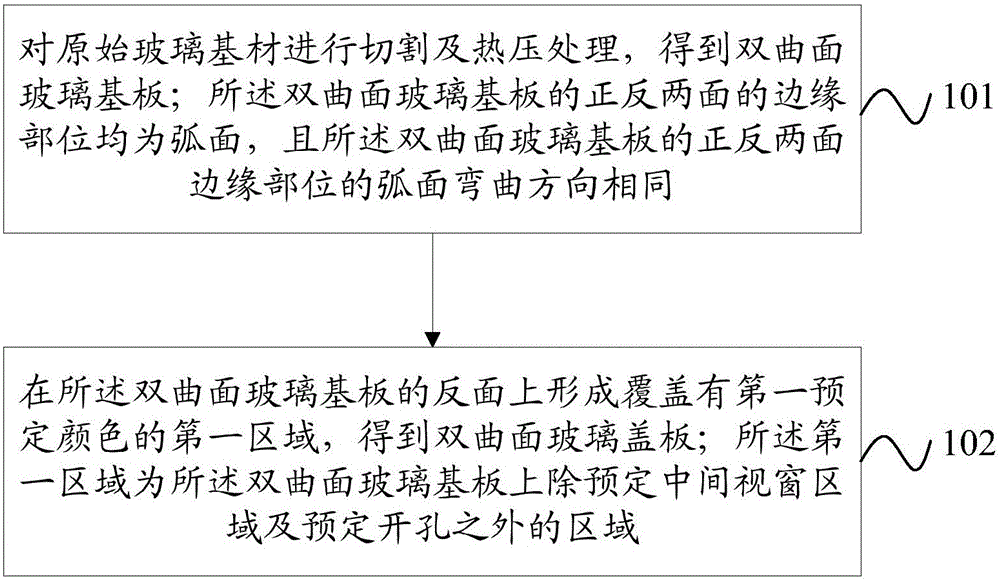

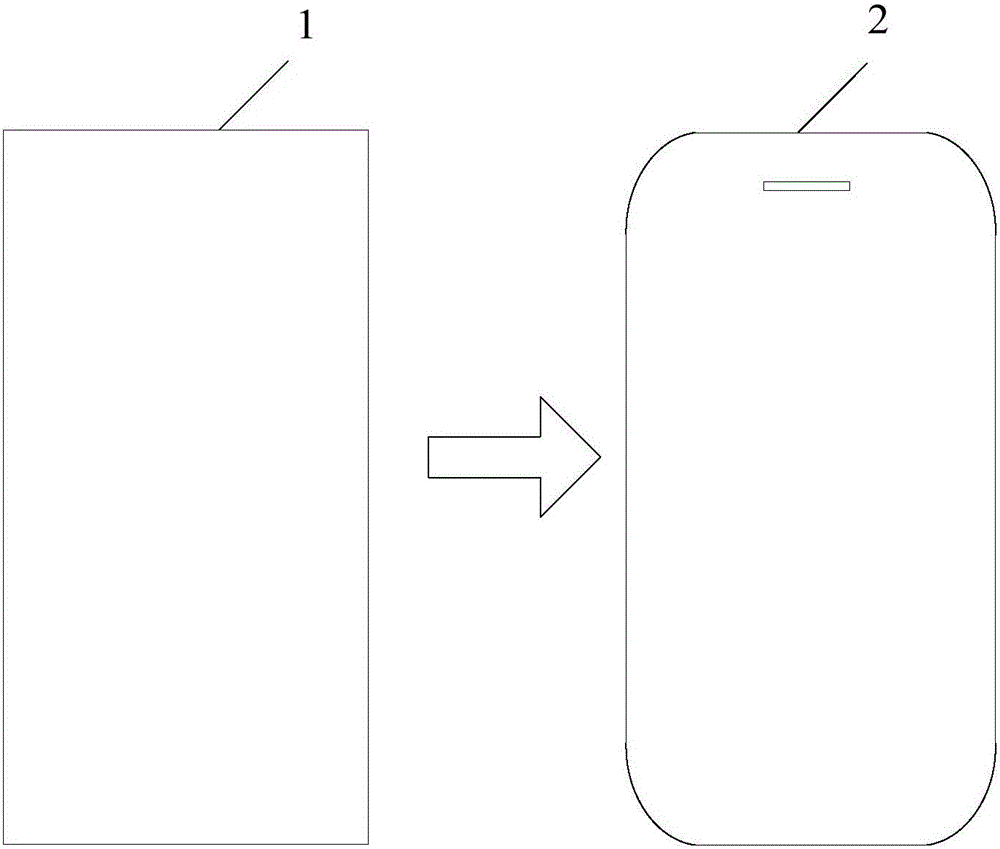

[0020] Such as figure 1 As shown, the manufacturing method of the glass cover plate of the embodiment of the present invention includes:

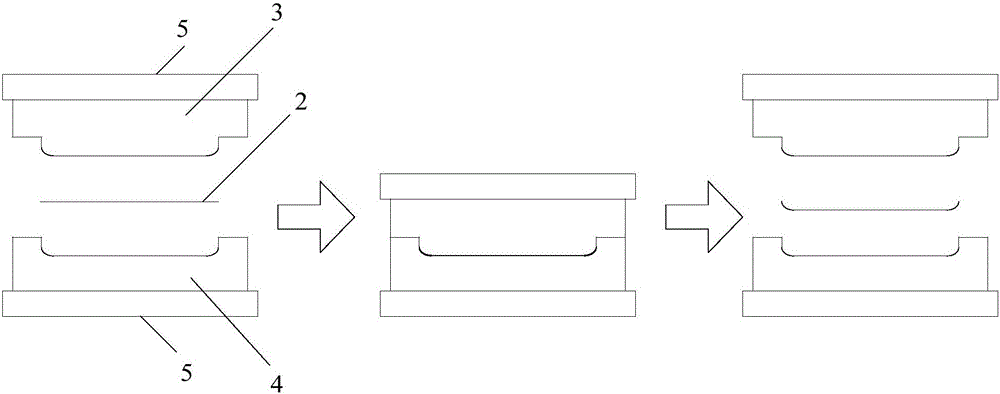

[0021] Step 101, cutting and hot-pressing the original glass substrate to obtain a double-curved glass substrate. The edges of the front and back sides of the hyperboloid glass substrate are arc surfaces, and the curvature direction and radian of the arc surfaces of the front and back sides of the hyperboloid glass substrate are the same.

[0022] Here, the 3D hyperboloid glass is obtained by cutting and hot-pressing the original glass substrate, and the glass cover plate made of the 3D hyperboloid glass has a more beautiful and novel appearance effect, and has a better visual effect .

[0023] Step 102, forming a first area covered with a first predetermined color on the reverse surface of the hyperbolic glass substrate to obtain a hyperbolic glass cover plate. The first area is the area on the hyperboloid glass substrate except for the...

no. 2 example

[0109] An embodiment of the present invention provides a glass cover plate, the edges of the front and back sides of the glass cover plate are both curved surfaces, and the curved surfaces of the front and back sides of the glass cover plate are curved in the same direction;

[0110] A first area covered with a first predetermined color is formed on the reverse side of the glass cover, and the first area is the area on the glass cover except for the predetermined middle window area and the predetermined opening.

[0111] The glass cover of the embodiment of the present invention is a 3D hyperboloid glass cover with a specific color, which has a novel shape and good visual effects; it provides very differentiated effects and experiences in many consumer electronic products, and satisfies people's expectations The high-quality appearance of the glass cover plate is required; and the manufacturing cost is low, which can be mass-produced and has wide application prospects. It effe...

no. 3 example

[0114] Since the glass cover plate in the embodiment of the present invention is applied to a mobile terminal, the embodiment of the present invention further provides a mobile terminal, including: the glass cover plate described in the foregoing embodiments.

[0115] The mobile terminal of the present invention may be, for example, mobile electronic devices such as mobile phones and tablet computers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Total thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com