Light distribution method of vehicle brake lamp

A technology for automobile braking and light distribution mirrors, which is applied to electric light sources, components of lighting devices, lighting devices, etc., can solve the problems of inability to meet continuous and uniform lighting effects, and achieve uniform lighting effects and uniform and beautiful lighting. , structure and light source selection, a wide variety of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

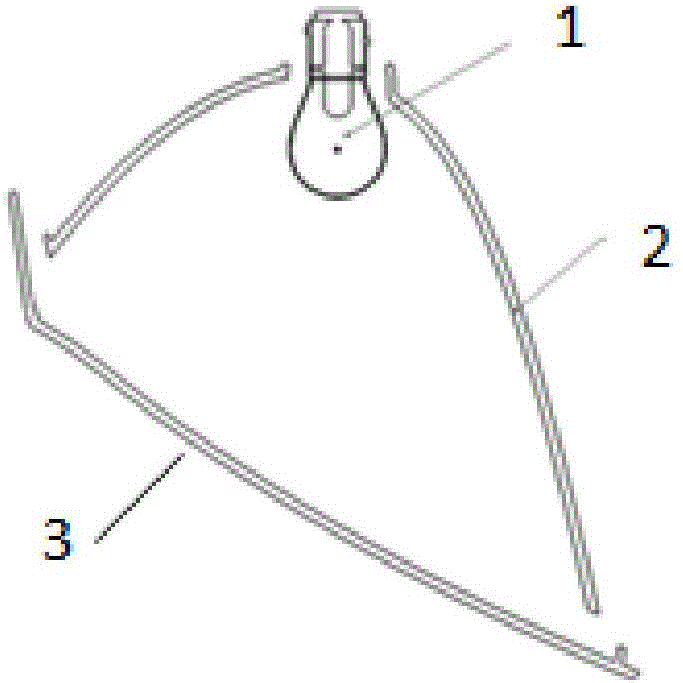

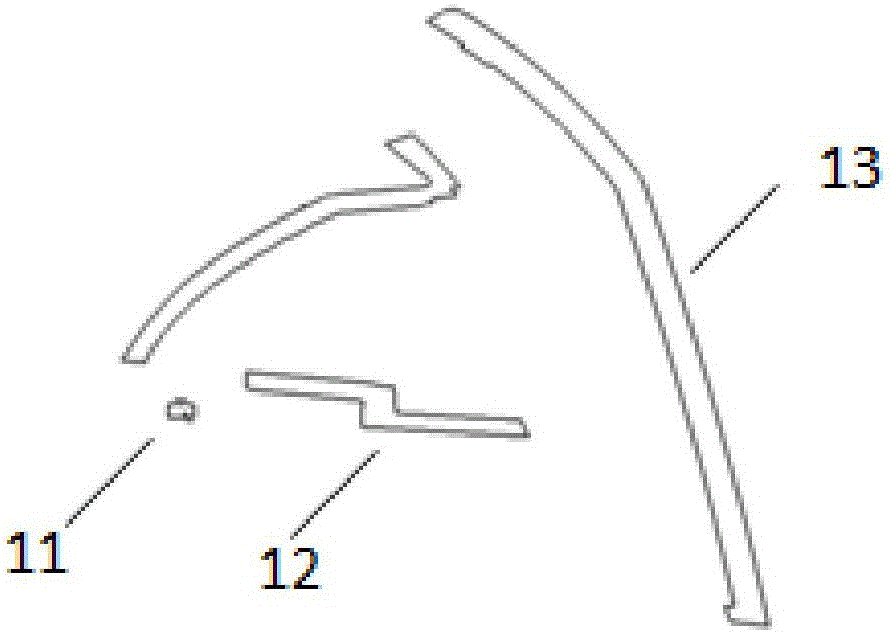

[0045] refer to Figure 5 : This light distribution scheme is realized by adopting LED+reflector+discrete material inner light distribution mirror, and the continuous and uniform lighting effect of the brake light is obtained. The LED can be arranged on the circuit board, and the light is fully reflected by the reflector and diffused through the inner light distribution mirror with discrete materials, achieving the effect of uniform light emission. The base material of the internal light distribution lens can be PMMA or PC material, and the discrete material can be DF22 or DF23. It can be understood that if the discrete material is configured in the base material of the inner light distribution mirror, it can be configured in various combinations, such as the configuration of PMMA+DF22, the configuration of PMMA+DF23, the configuration of PC+DF22 or the configuration of PC+DF23 Wait. In addition, the base material of the internal light distribution mirror in this embodiment ...

Embodiment 2

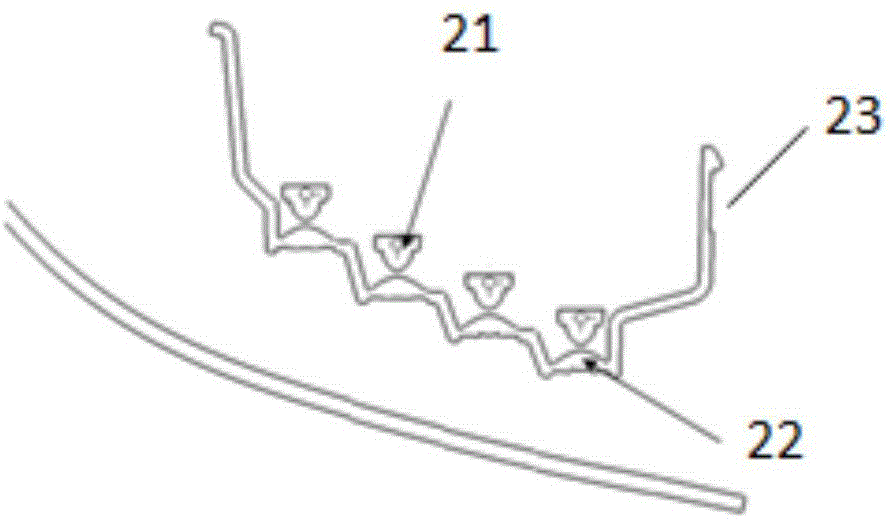

[0047] refer to Image 6 , Image 6 The light distribution method in is reflective. Through the reflector composed of 8 individual reflective surfaces such as a~h, the total reflected light is irradiated on the inner light distribution mirror with discrete materials on the large curved surface, and the large curved surface The surface of the inner light distribution mirror presents a continuous and uniform lighting effect. The base material of the inner light distribution mirror is PMMA or PC material, and the discrete material can be DF22 or DF23. It can be understood that if the discrete material is configured in the base material of the inner light distribution mirror, it can be configured in various combinations, such as the configuration of PMMA+DF22, the configuration of PMMA+DF23, the configuration of PC+DF22 or the configuration of PC+DF23 Wait. It can be understood that, as other modification schemes, a separate texture treatment can be performed on the surface of ...

Embodiment 3

[0049] refer to Figure 7 , Figure 7 The light distribution method is direct type. In this embodiment, there is no reflector. Multiple groups of LED lamps are combined to form a direct light source array. The lighting effect of the insulation. According to the characteristics of the large curved surface, the arrangement of multiple LEDs can be evenly distributed according to the size of the curved surface.

[0050] Compared with the prior art, the beneficial effects of the present invention are as follows:

[0051] 1. The light distribution scheme of the present invention is adopted, that is, a new type of scattering material with discrete materials is used as the inner light distribution mirror, so that the output light can be scattered more evenly (such as figure 2 As shown), it can effectively weaken and eliminate the bright and dark areas formed on the surface of the inner light distribution mirror after lighting, so that the illumination is uniform and beautiful, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com