A sediment transport device for a dredger

A dredger and sand technology, applied in the field of sand transport devices, can solve the problems of hull trauma, height drop, unfavorable grasping of the grab bucket, etc., and achieve the effect of convenient operation and avoiding impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

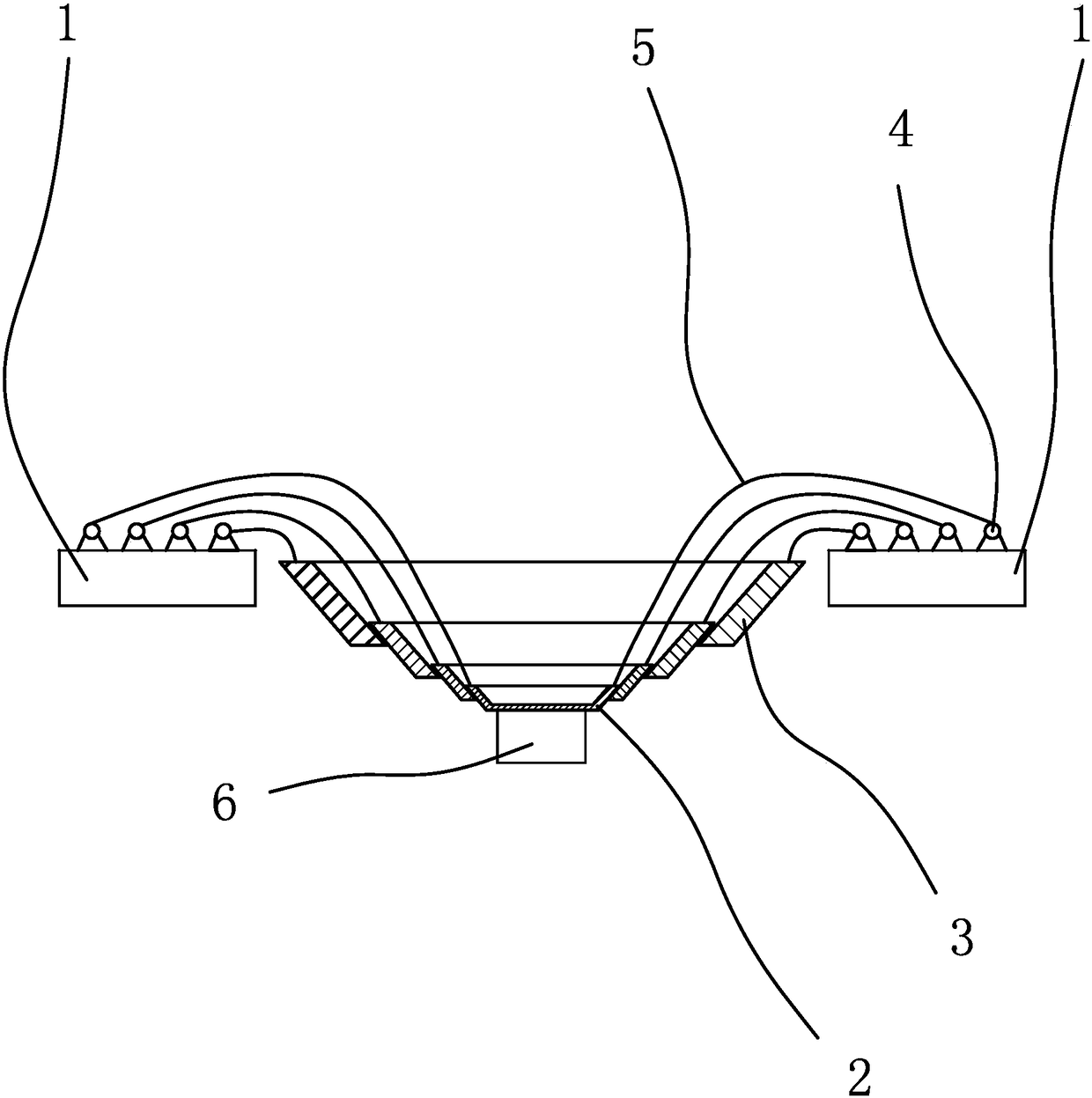

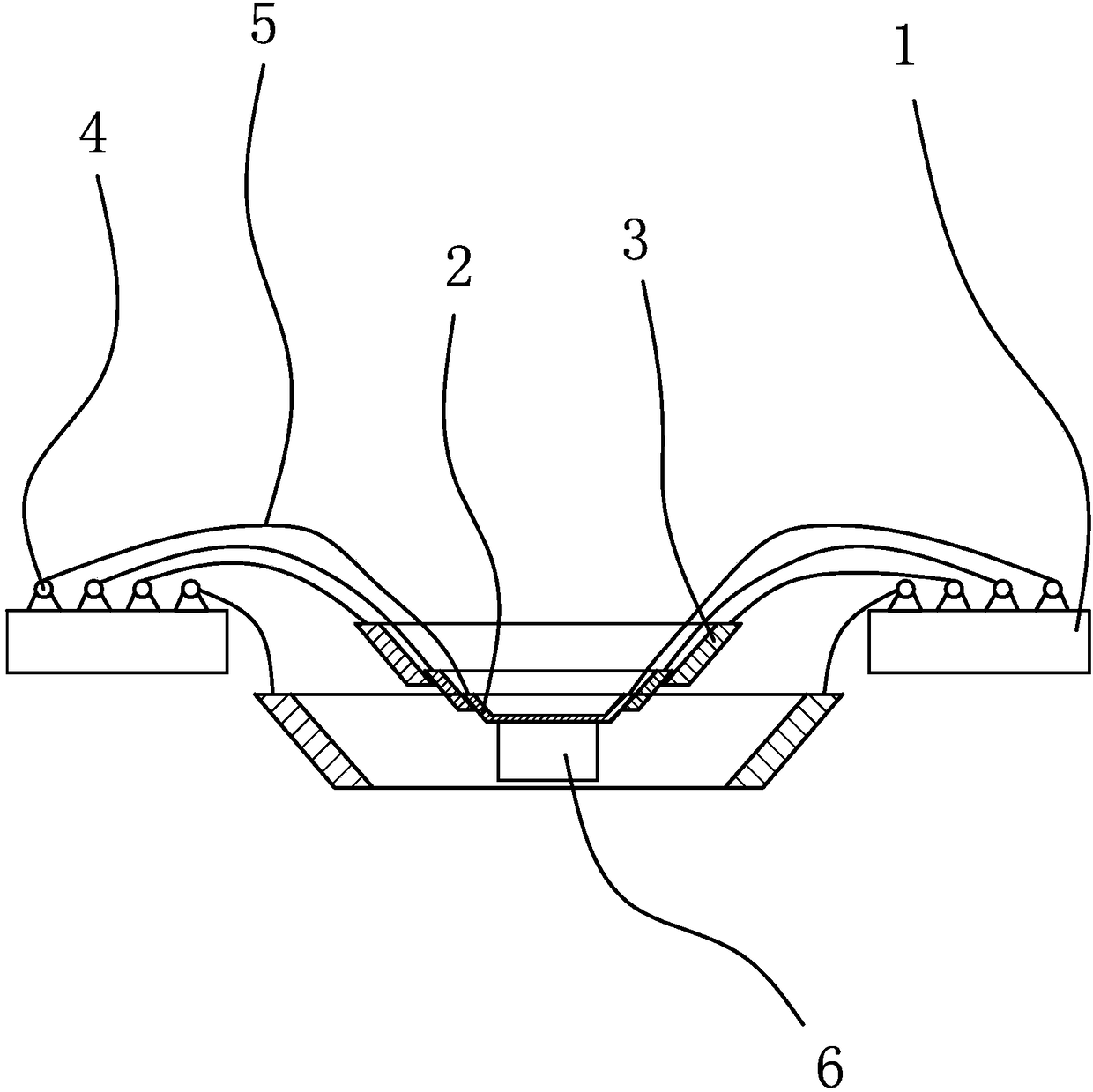

[0024] like Figure 1-4 As shown, a dredging ship's sediment transportation device, the dredging ship includes a hull 1, and a through hole is arranged in the hull 1, and the through hole runs through the outer plate and the main deck of the hull 1, and the sediment The transport device is arranged in the through hole of the hull 1;

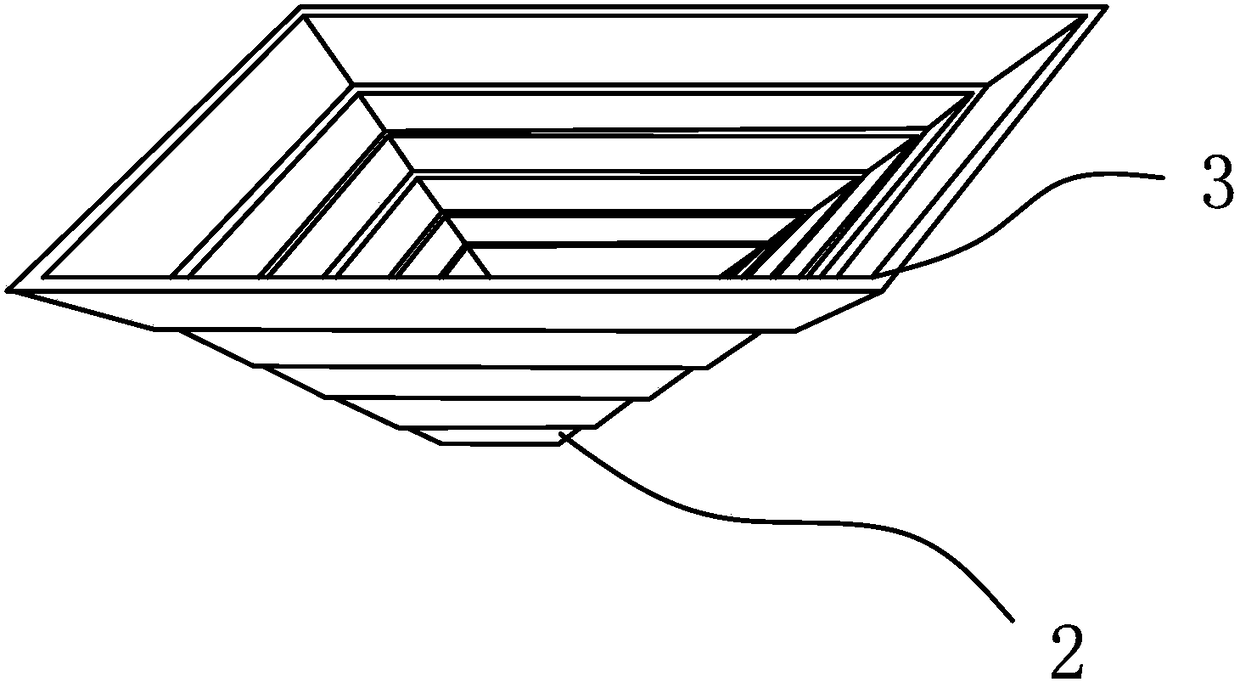

[0025] The sediment transport device of the dredger comprises a cabin body 2 with an open top and a closed bottom and at least two conical cabin sections 3, the cabin body 2 is conical and the width of the opening end is greater than the width of the bottom, and the cabin sections 3 are two Both ends are open and the opening width at the top of the cabin section 3 is greater than the opening width at the bottom end. The innermost cabin section 3 is sleeved outside the cabin body 2, and the outer cabin section 3 is sleeved outside the inner layer cabin section 3. The bottom opening of the inner cabin section 3 matches the size of the top opening ...

Embodiment 2

[0035] This implementation is basically the same as Embodiment 1, the difference is that the sediment transport device is arranged between two dredgers, both of which have a hull 1, and the tractors 4 are respectively It is arranged on the hulls 1 of the two dredgers and arranged symmetrically relative to the sediment transport device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com