Installation method and installation structure of large span space rebate continuous steel truss

An installation method and installation structure technology, which are applied to truss-type structures, girders, trusses, etc., can solve the problems of cumulative installation errors, increase the uncertainty of subsequent segment cantilever benchmarks, and affect the control of engineering implementation. Installation control, increased flexibility, reduced installation deviation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

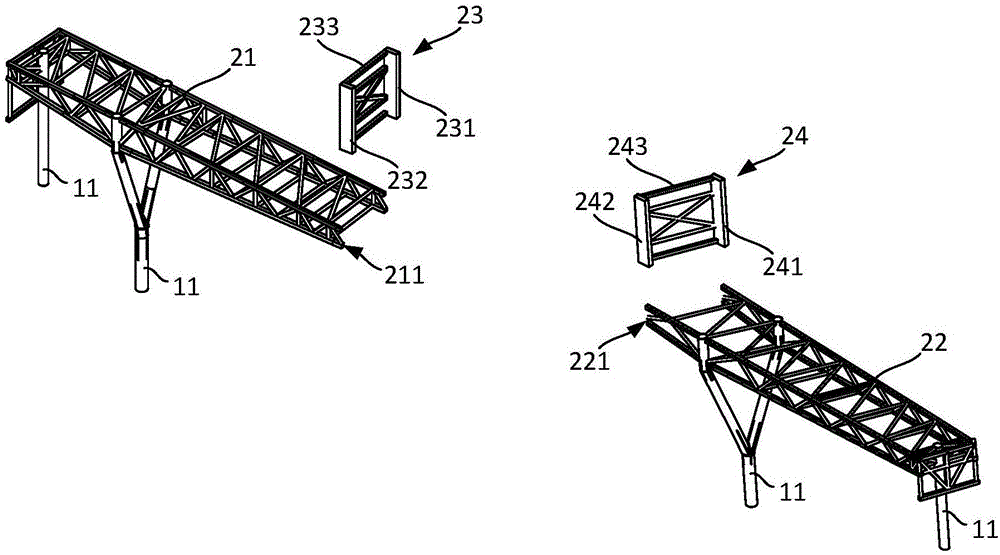

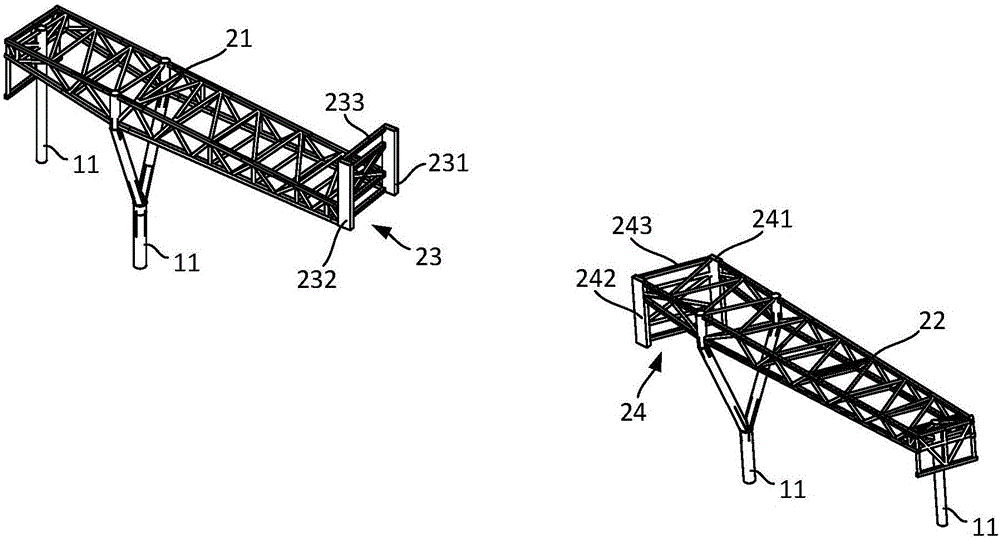

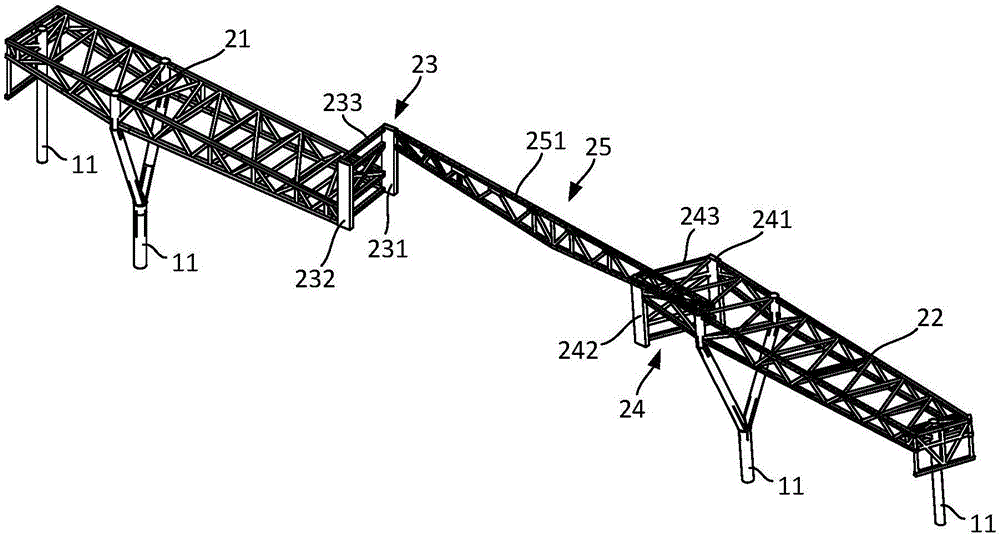

[0043] The invention provides an installation method and installation structure of a large-span continuous steel truss truss, which overcomes the shortcomings of the current large-span continuous steel truss cantilever installation technology, simplifies the installation process, and aims at high headroom and large-span spaces. According to the characteristics of continuous roof steel trusses, the method of conventional axial segmental cantilever installation is improved, and an outrigger cantilever installation technology suitable for large-span space drop-down continuous steel truss high-altitude rapid closing is formed. The present invention reuses the vertical bearing capacity of the roof column in the structural main body at both ends of the steel truss, adopts the cantilever installation of the apex span truss, and then installs the drop-d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com