Gas-liquid separator, air conditioner system and control method of air conditioner system

A gas-liquid separator and air-conditioning system technology, which is applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., to achieve the effect of improving reliability, improving system reliability, and ensuring system reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

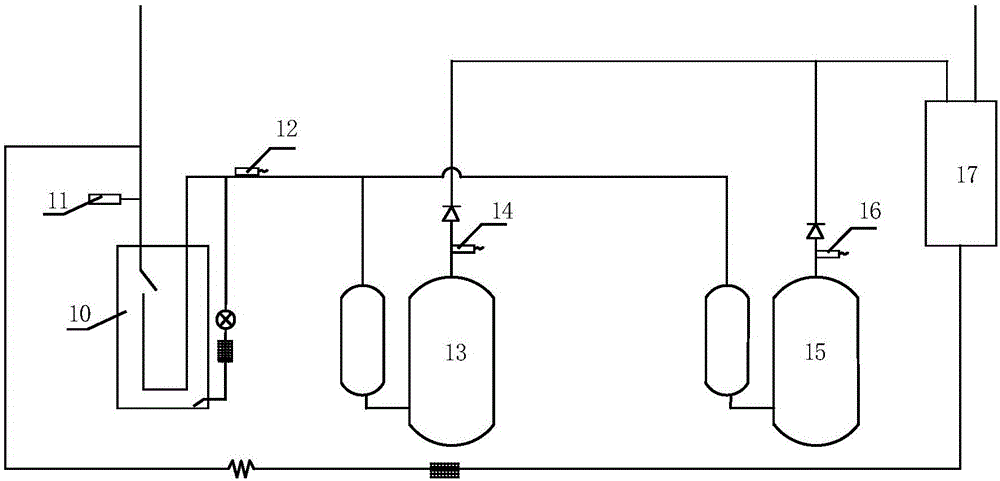

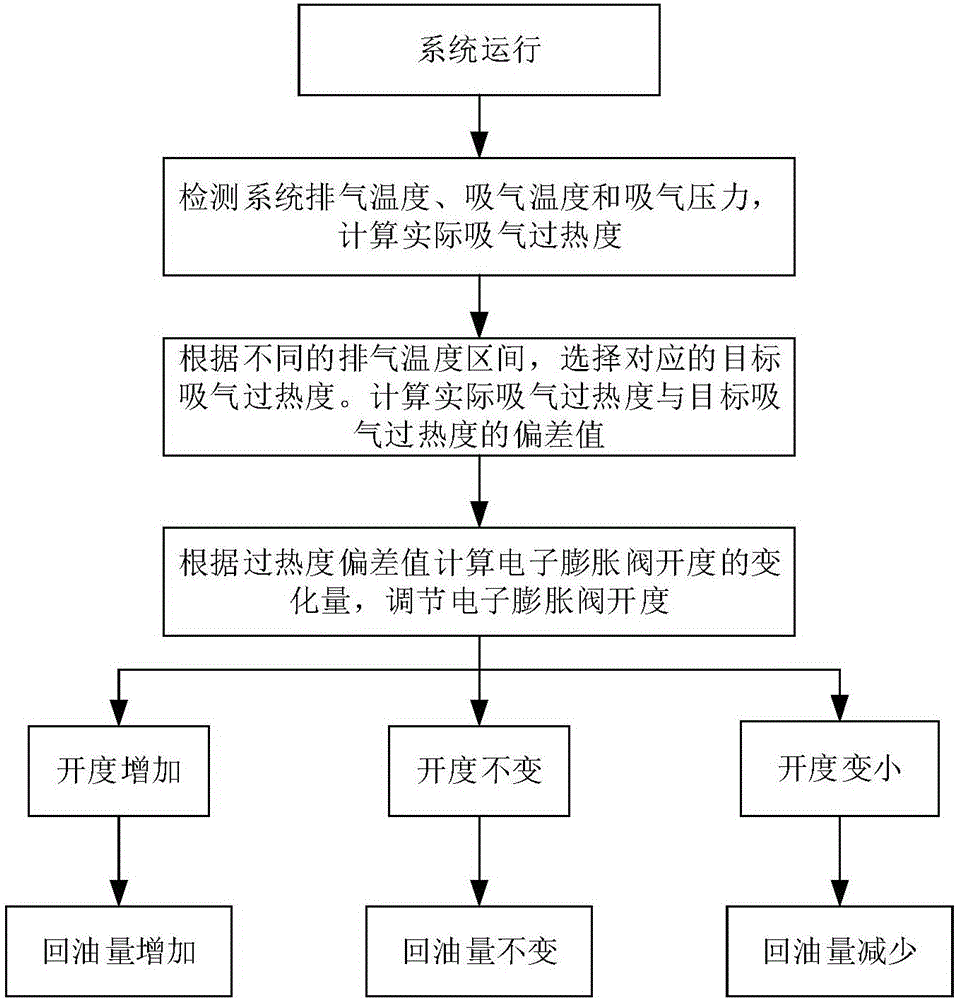

[0040] Aiming at the problem that the gas-liquid separator in the prior art cannot adjust and control the oil return volume and liquid return volume, the present invention provides a gas-liquid separator capable of adjusting the oil return volume.

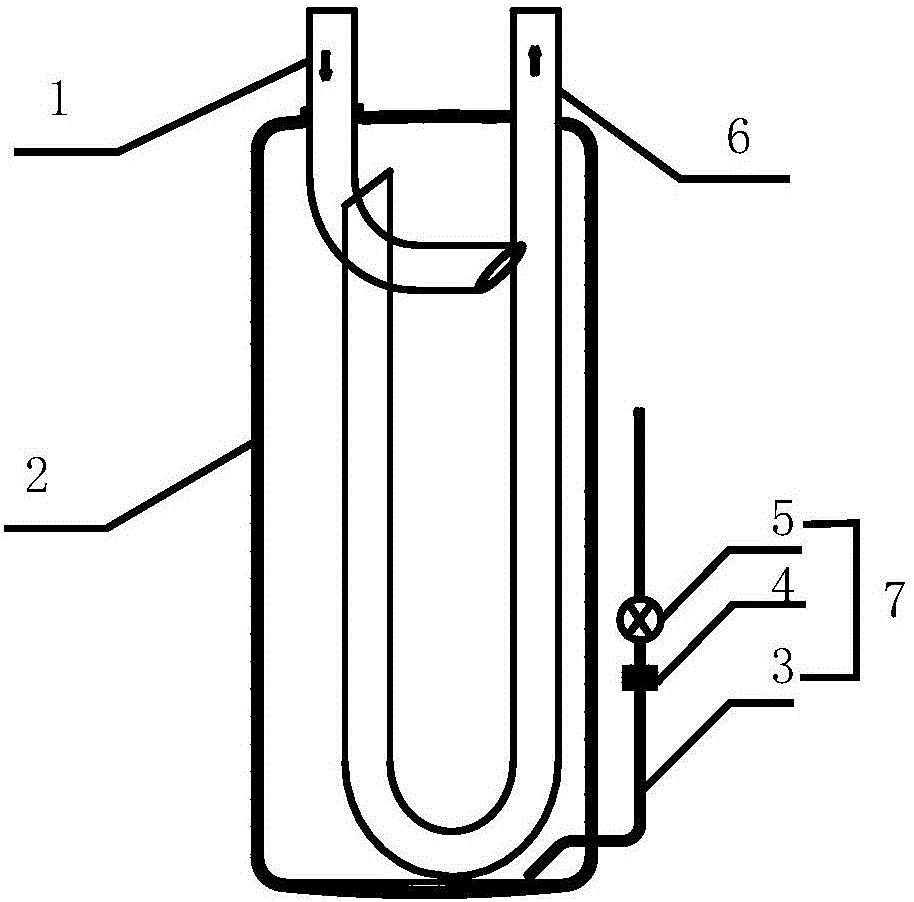

[0041] like figure 1 As shown, the gas-liquid separator of the present invention includes a casing 2 , an air outlet pipe 6 and an oil return assembly 7 .

[0042] Wherein, the oil return assembly 7 includes an oil return valve 5 , the inlet end of the oil return valve 5 communicates with the inside of the housing 2 , and the outlet end of the oil return valve 5 communicates with the air outlet pipe 6 .

[0043] Because the gas-liquid separator of the present invention is provided with an oil return assembly, one end of the oil return valve in the oil return assembly communicates with the inside of the housing 2, and the other end communicates with the air outlet pipe 6. Therefore, when there is a high-speed flow in the air outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com