Method and device for displaying flaw detection data of train wheel set

A technology of train wheels and data, which is applied in the direction of measuring devices, processing detection response signals, and using sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve the problems that the flaw detection data display results are not intuitive, comprehensive, and irrelevant, etc., to achieve Intuitive and comprehensive, the effect of improving analysis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

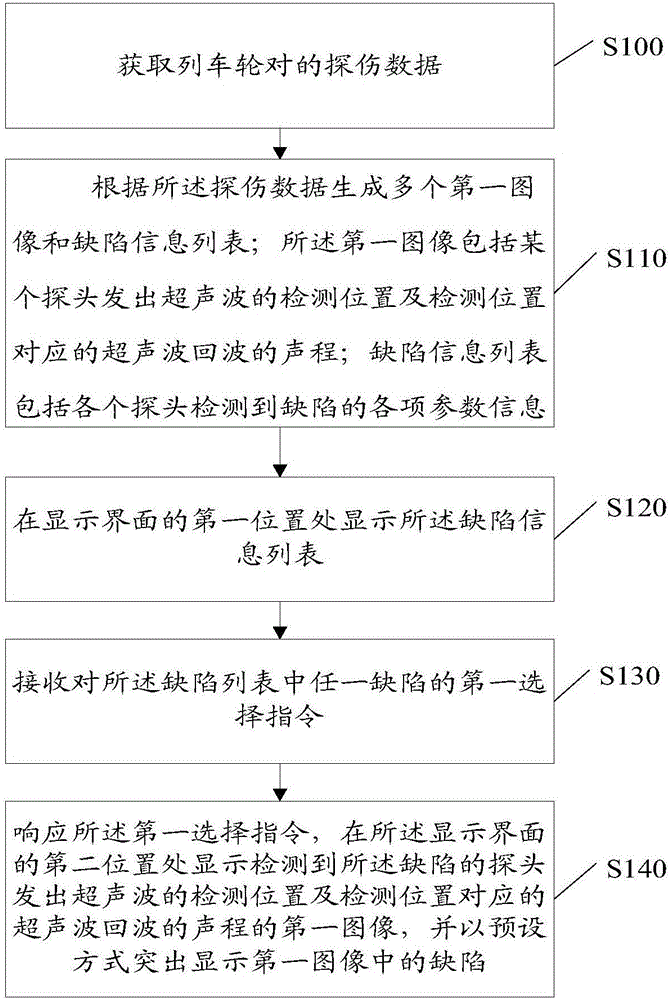

[0062] This embodiment provides a method for displaying flaw detection data of train wheelsets, such as figure 1 As shown, the method includes:

[0063] S100: Obtain flaw detection data of train wheelsets;

[0064] The flaw detection of the train wheel set is carried out through the train wheel set ultrasonic flaw detection system, and the flaw detection data is collected. The flaw detection data includes various data involved in the flaw detection process of each probe on each detection position of the train wheel set, such as the train wheel set data (train wheel set pair number), relevant data of each defect and crack (ultrasonic amplitude, sound path), flaw detection tool data (channel number to which the probe belongs, probe type), etc.

[0065] S110: Generate a plurality of first images and defect information lists according to the flaw detection data;

[0066] Wherein, the first image includes the detection position where a certain probe emits ultrasonic waves and the...

Embodiment 2

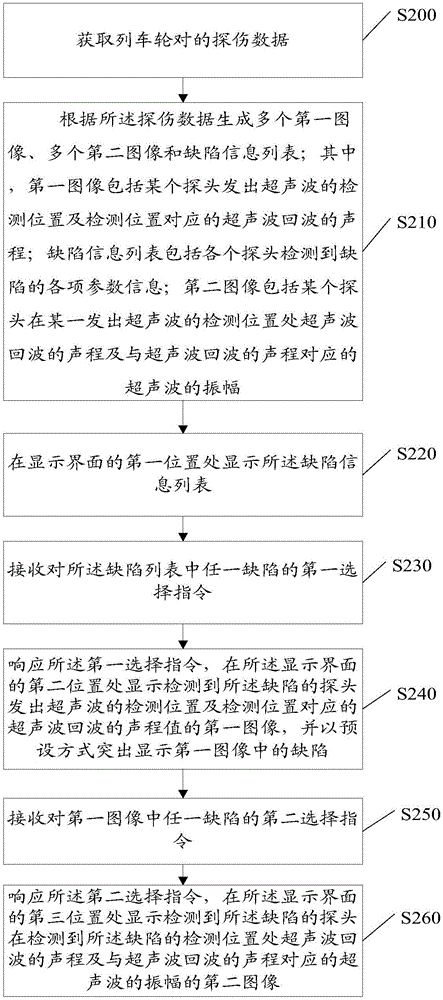

[0081] This embodiment provides a method for displaying flaw detection data of train wheelsets, such as figure 2 As shown, the method includes:

[0082] S200: Obtain flaw detection data of the train wheel set.

[0083] S210: Generate a plurality of first images, a plurality of second images, and a defect information list according to the flaw detection data; wherein, the first image includes a detection position where a certain probe emits an ultrasonic wave and a sound path of an ultrasonic echo corresponding to the detection position; The defect information list includes various parameter information of defects detected by each probe, and the first image and the defect information list are the same as those in the first embodiment, and will not be repeated here.

[0084] Specifically, the second image is an ultrasonic scan image, which is displayed in the form of a two-dimensional image, including the sound path of the ultrasonic echo of a certain probe at a detection posi...

Embodiment 3

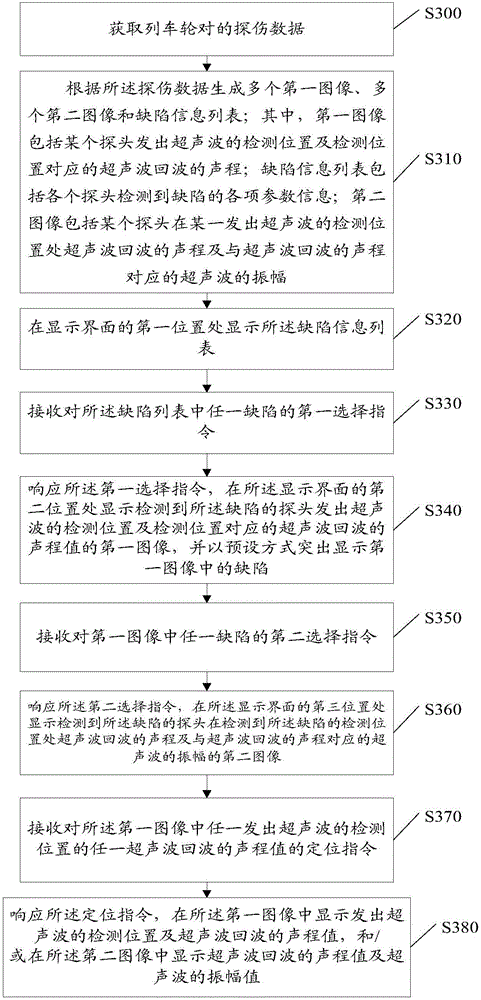

[0093] This embodiment provides a method for displaying flaw detection data of train wheelsets, such as image 3 As shown, the method includes:

[0094] S300: Obtain flaw detection data of train wheelsets.

[0095] S310: Generate a plurality of first images, a plurality of second images, and a defect information list according to the flaw detection data; wherein, the first image includes a detection position where a certain probe emits an ultrasonic wave and a sound path of an ultrasonic echo corresponding to the detection position; The defect information list includes various parameter information of defects detected by each probe; the second image includes the sound path of the ultrasonic echo of a certain probe at a detection position where the ultrasonic wave is emitted and the ultrasonic wave corresponding to the sound path of the ultrasonic echo. amplitude.

[0096] S320: Display the defect information list at the first position on the display interface.

[0097] S330...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com