Automatic plastic coloring machine

A fully automatic, plastic technology, applied in the field of plastic processing equipment, to achieve the effect of saving time and effort, good visual effect and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

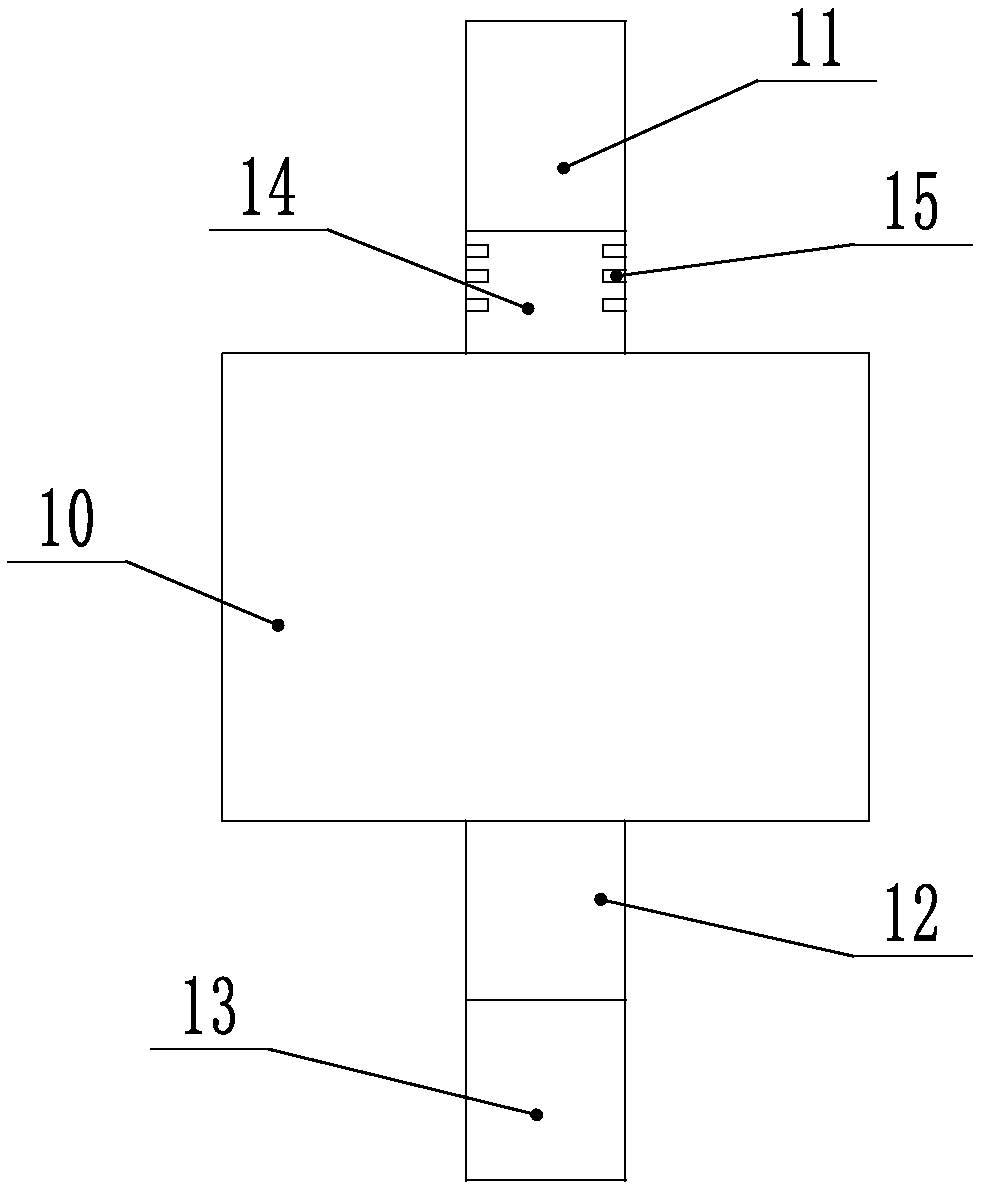

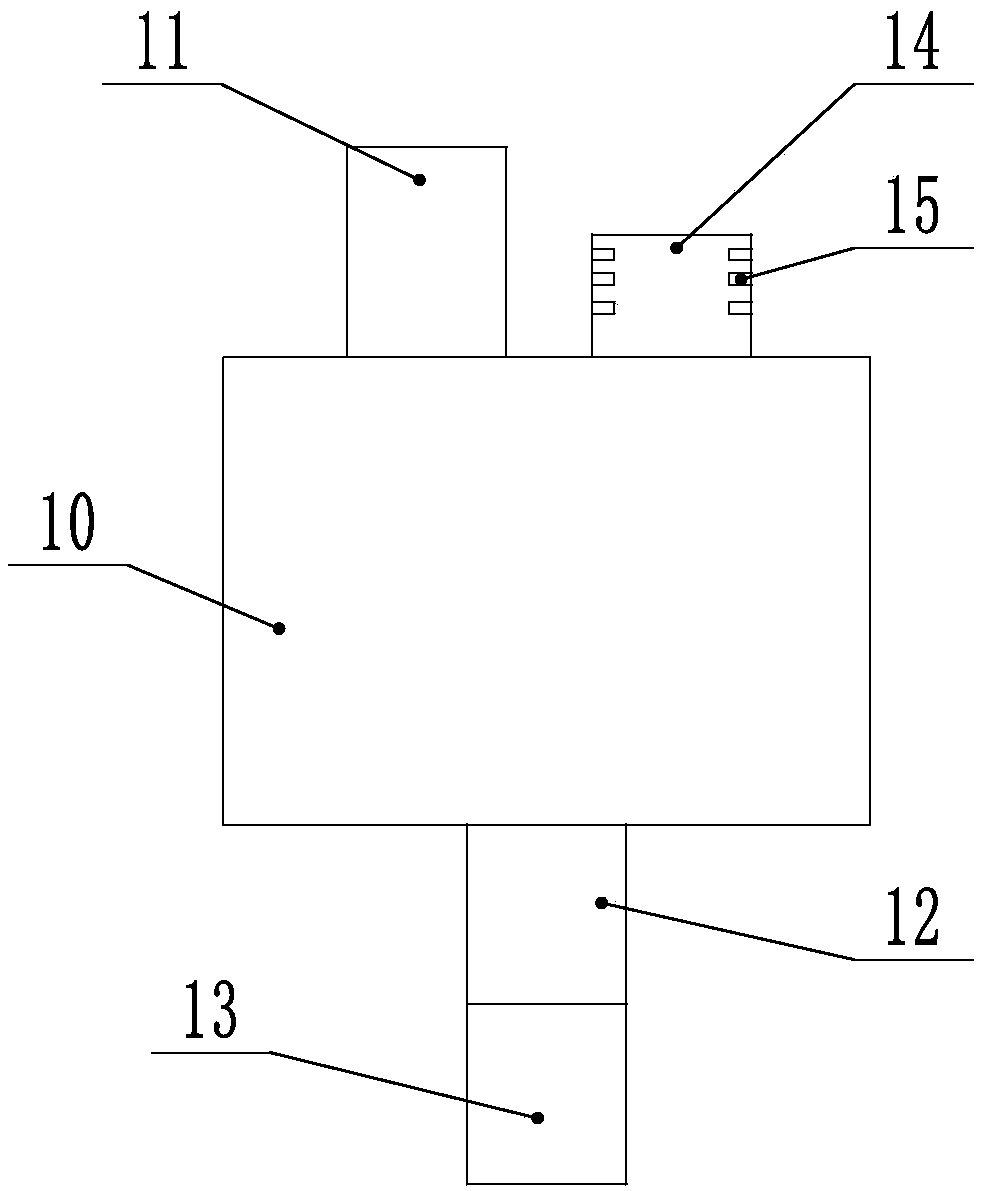

[0018] refer to figure 1 , 2 , is a kind of fully automatic plastic coloring machine disclosed by the present invention, comprising a mixer 10, the upper side of the mixer 10 is provided with a feed port, the top of the mixer 10 is provided with a metering bin 11, and the lower side of the metering bin 11 is provided with a discharge The mouth and the upper side are provided with a feed port, and the feed port of the mixer 10 is connected with the discharge port of the metering bin 11; The upper side of the bin 12 is provided with a feed port, and the lower side is provided with a discharge port. The feed port of the storage bin 12 is connected with the discharge port of the mixer 10. A valve controlled by a controller that controls the communication between the storage bin 12 and the mixer 10 is provided on the mouth. The main purpose of setting up the metering bin is to control the amount of raw materials entering the mixer, so it is relatively simple to feed the metering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com