Product conveyer

A conveyor, product technology, applied in the direction of conveyor objects, transportation and packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

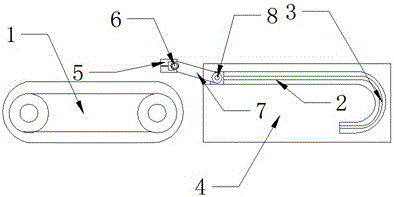

[0016] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

[0017] The product conveyor is placed at the end of the production line 1 and clamps the product, and is connected to the guide rail assembly of the clamp assembly. The guide rail assembly consists of: a horizontal guide rail 2, and an arc-shaped guide rail 3 extending from the horizontal guide rail 2.

[0018] In order to enable the horizontal guide rail 2 and the arc guide rail 3 to be on the same plane and be stably fixed, the product conveyor further includes: a base plate 4 fixed to the transverse guide rail 2 and the arc guide rail 3 .

[0019] The arc guide rail 3 can be above the transverse guide rail 2 or below the transverse guide rail 2, depending on whether the position to be transported is higher than the production line 1 or lower than the production line 1. As a preference, the arc guide rail 3 is half Round rails.

[0020...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com