Device for eliminating rail gnawing of trolley of large-size bridge crane

A technology of bridge cranes and cranes, applied in the direction of traveling mechanism, transportation and packaging, load hanging components, etc., to achieve the effects of eliminating friction and gnawing rails, simple structure, and ensuring personnel safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

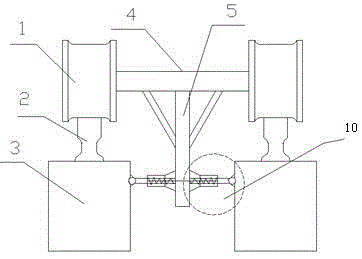

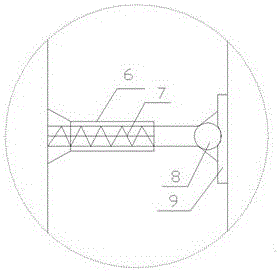

[0016] In order to enable those skilled in the art to better understand the technical solution of the present invention, the following in conjunction with the attached Figure 1-2 The present invention is further analyzed.

[0017] Such as Figure 1-2 As shown, a device for eliminating the rail gnawing of a large bridge crane trolley is to add a disc spring support arm 10 at the bottom of the existing bridge crane trolley, and the device includes a main frame 5, a disc spring support arm 10, and a rolling ball 8 And the disc spring 7, the disc spring shell 6 is installed on the periphery of the disc spring 7; the main body frame 5 and the bottom connecting body 4 of the crane trolley are fixedly connected by high-strength large-diameter bolts; the two ends of the connecting body 4 at the bottom of the crane trolley are provided with trolley wheels 1, The wheel 1 is vertically set on the trolley track 2, and the trolley track 2 is set on the girder 3 of the bridge crane; two h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com