Powder metallurgical particle vibration grading device

A classification device and powder metallurgy technology, applied in classification, solid separation, chemical instruments and methods, etc., can solve the problems of difficult cleaning, high cost, difficulty in making screen meshes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

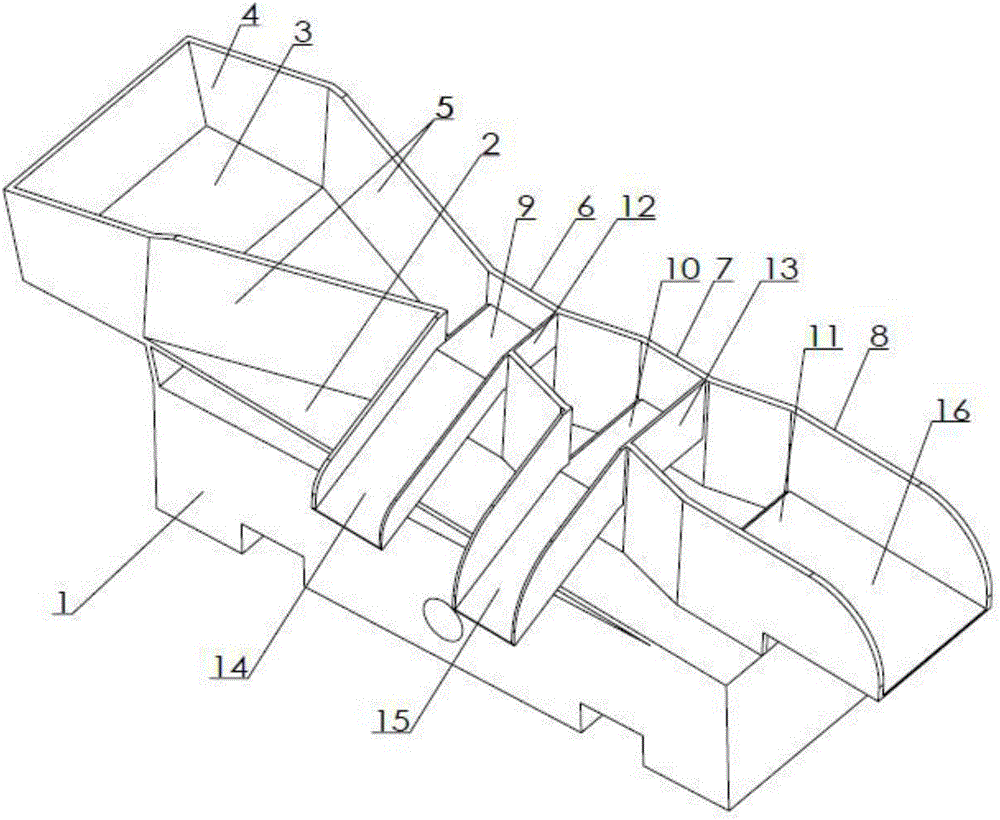

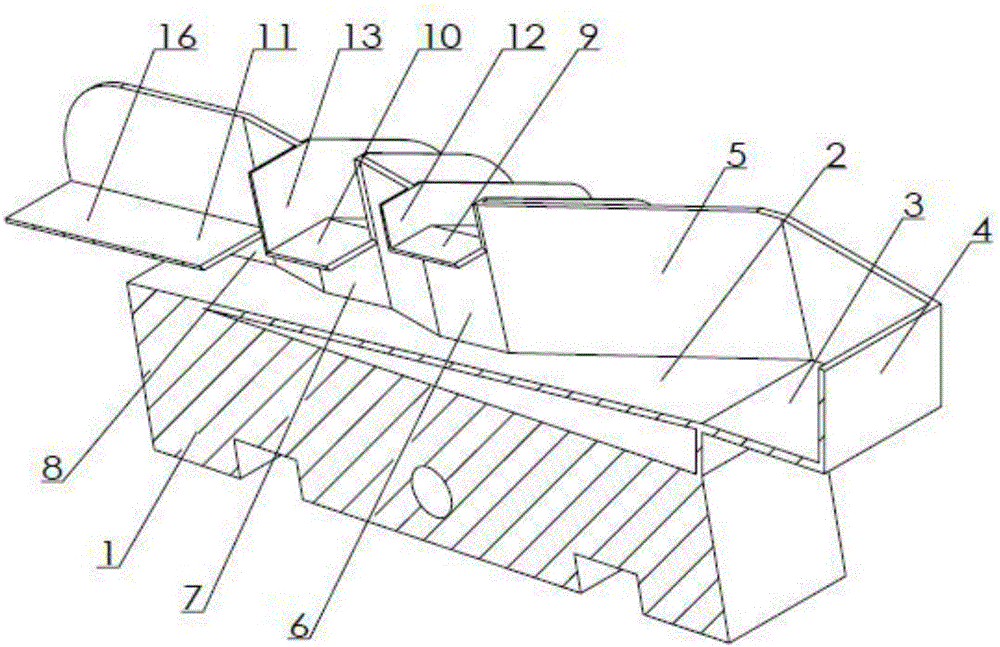

[0012] Examples of the present invention figure 1 , 2 As shown, the powder metallurgy particle vibration classification device includes a vibrating table to provide vibration power transmission. A vibrating block 1 is provided on the vibrating table, which can vibrate back and forth in the left and right horizontal directions. A slope 2 is connected to the vibrating block with an angle of 3 to 3. 15 degrees, with 5 to 8 degrees being the best, which can provide guidance for the direction of movement without causing dumping. There are left and right symmetrical side plates connected to the slope, and a material storage platform 3 is connected to the upper end of the slope. The coaming 4 connected to the side plates is used to contain powder particles. The side plates are divided into upper section 5 and lower section from top to bottom along the slope. There are at least two levels of screening areas. In this embodiment, there are three levels, which are the first level 6, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com