A garbage can that can crush garbage

A trash can and garbage technology, applied in the field of trash cans, can solve the problems of occupying space and affecting the efficiency of the use of the volume in the bucket, and achieve the effects of easy storage, reducing the surface area of garbage, and reducing the frequency of dumping garbage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

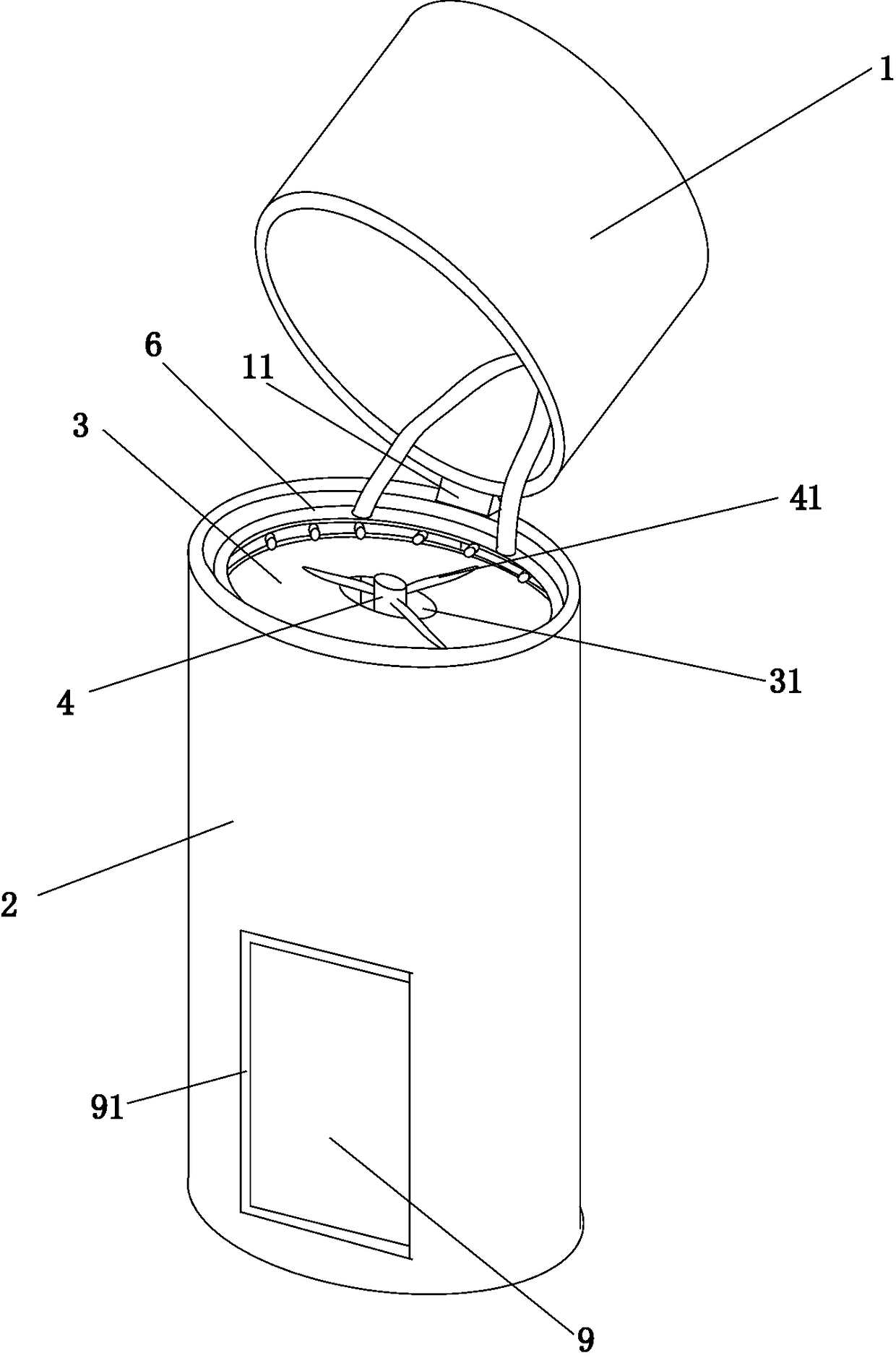

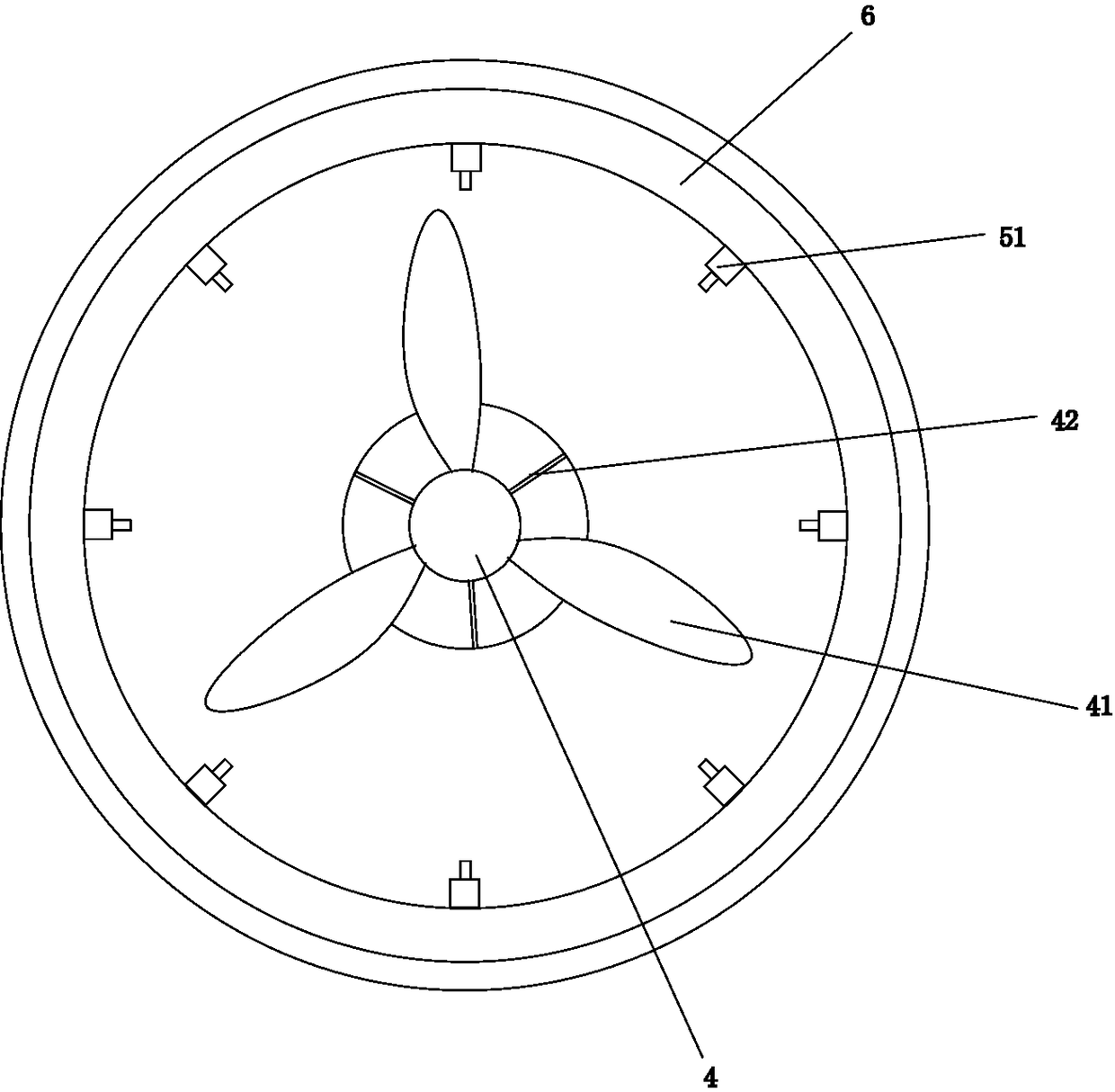

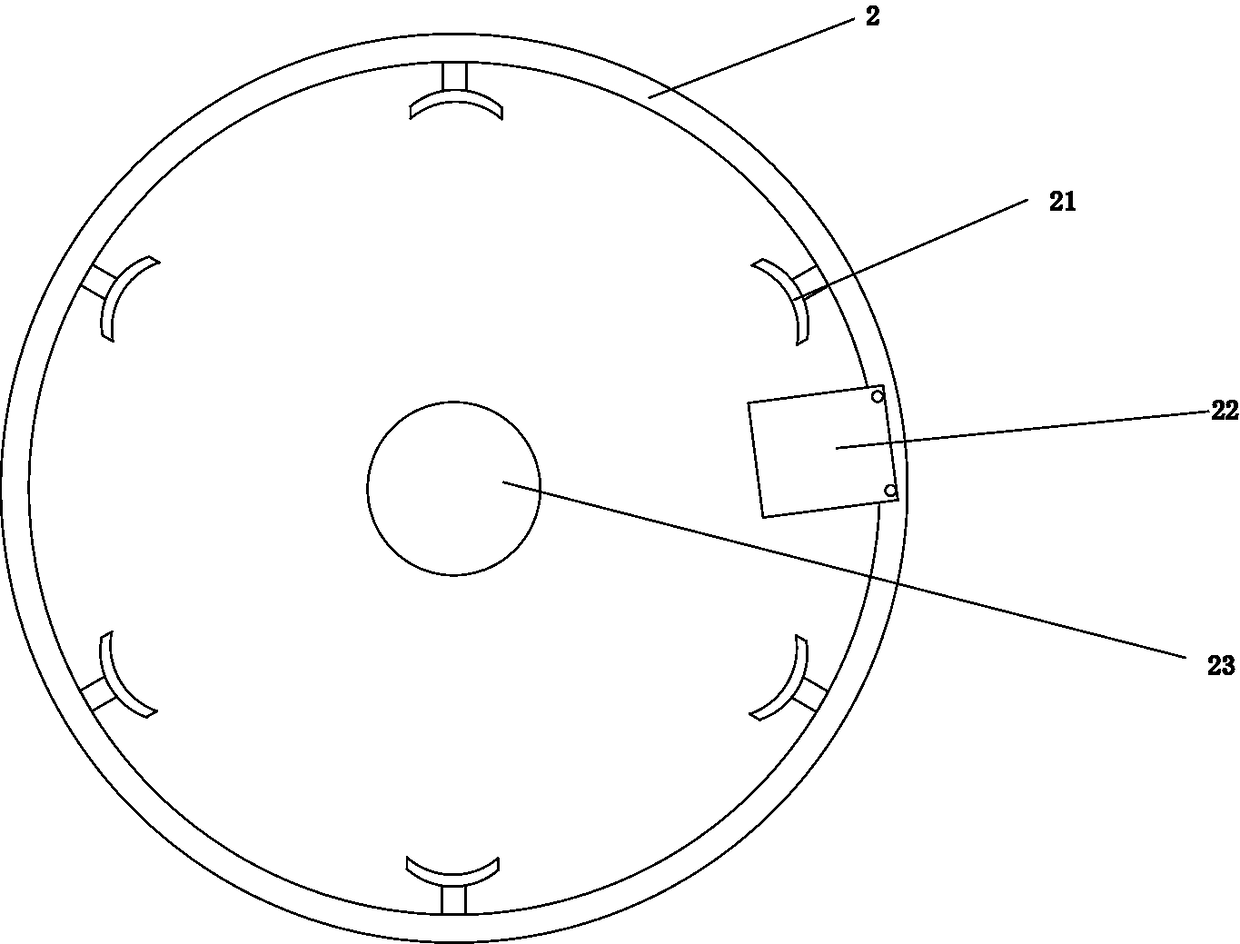

[0021] Example: as Figure 1 to Figure 6 As shown, a trash can that can crush garbage, including a barrel body 2 and a barrel cover 1, the barrel body 2 and the barrel cover 1 are connected by an electric rotating shaft 11, the barrel cover 1 is provided with an annular sealing ring 14, and the barrel body 2 is provided with There is an annular sealing groove 24 matched with the annular sealing ring 14, so that the barrel body 2 and the barrel cover 1 can be relatively sealed to prevent the gas in the barrel body 2 from escaping. A partition 3 is arranged in the barrel 2, a through hole 31 is arranged in the middle of the partition 3, the partition 3 is in the shape of an inverted cone, and the through hole 31 is arranged in the middle of the partition 3, because the partition 3 is an inverted cone, and the garbage When poured on the partition 3, it will automatically move in the direction of the passage hole 31. The passing hole 31 is provided with a rotating motor 4 , and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com