Safe and fast beam falling method for railway T-shaped beam

A technology of T-shaped beams and falling beams, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of beam overturning accidents, low efficiency, time-consuming and labor-intensive, etc., to eliminate deviation, reduce labor intensity, and improve construction efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

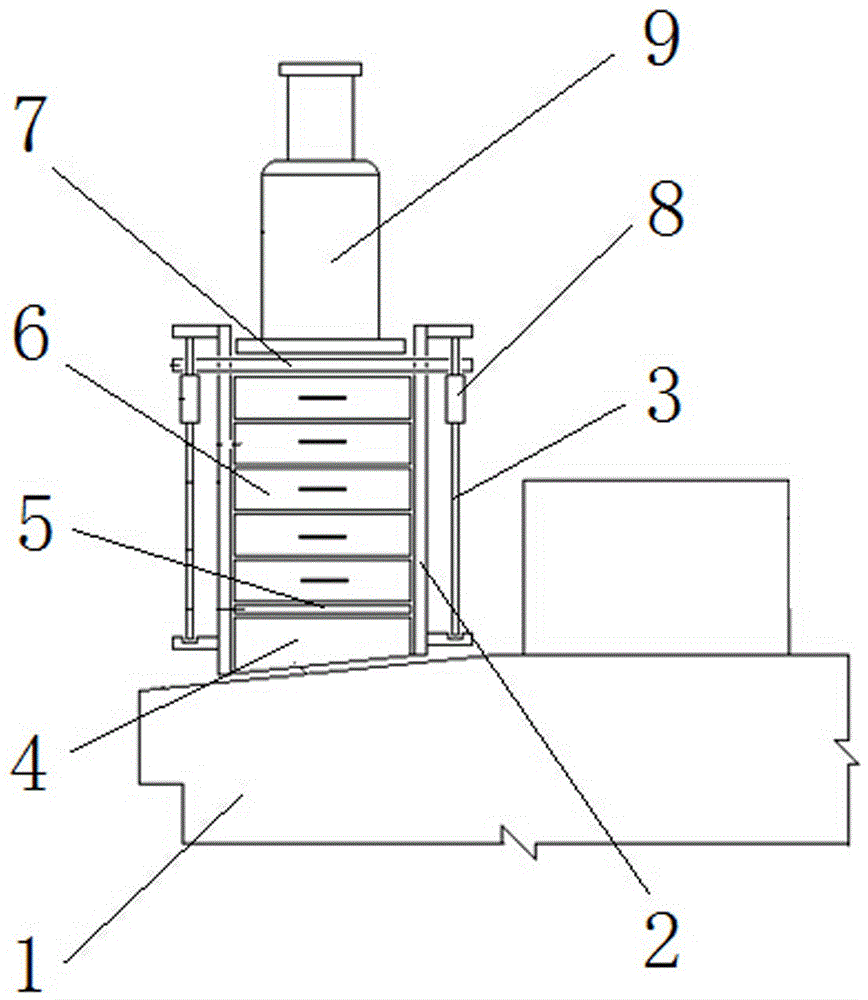

[0014] The method of safe and fast falling of railway T-shaped beams adopts the following steps: a. Before the T-shaped beam reaches the plane position through the beam-moving slide rail, the lifting and leveling device is placed in advance to ensure that the jack stroke meets the needs of lifting the T-shaped beam. The flat device includes a truss-type guide frame 2 arranged on the bridge pier cap stone 1 with an open front end. The left and right sides of the truss-type guide frame 2 are provided with a screw screw 3 placed vertically and fixed thereto. The truss-type guide The bottom end of the frame 2 is provided with adjusting bolts, and the truss-type guide frame 2 is provided with a leveling box 4 located at the bottom end and the upper end is open, and the bottom surface of the leveling box 4 is matched with the surface of the bridge pier cap stone 1, and A sand body is housed in the leveling box body 4, a steel backing plate 5 is placed above the leveling box body 4, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com