Electric eddy current damping magnetic spring based on multiple halbach permanent magnet arrays

An eddy current damping, permanent magnet array technology, applied in the direction of magnetic springs, springs, springs/shock absorbers, etc., can solve problems such as unfavorable use and maintenance of spring doors, equipment shaking and impact, high centrifugal force, etc., to increase dynamic damping Features, smooth action process, prevent excessive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

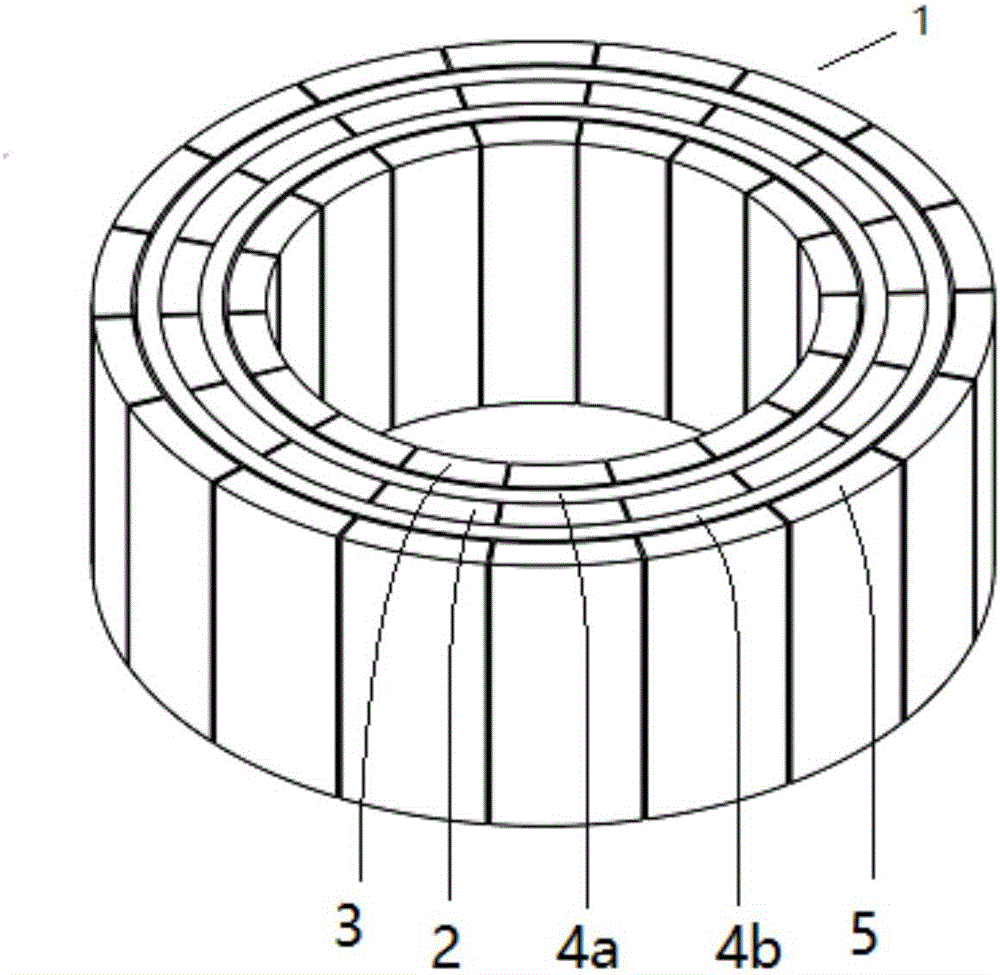

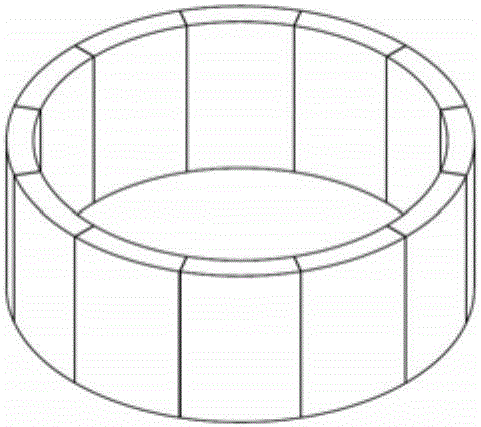

[0029] The first embodiment of the eddy current damping magnetic spring based on multiple halbach permanent magnet arrays proposed by the present invention is as follows figure 1 As shown, it can be set as a barrel spring formed by sheathing each component. The components of the eddy current damping magnetic force spring 1 based on a plurality of halbach permanent magnet arrays include an annular first halbach permanent magnet array 2, an annular second halbach permanent magnet array 3 and the first halbach permanent magnet array 2 and the second annular permanent magnet array 3. The first annular eddy current damper 4a between the halbach permanent magnet arrays 3; the eddy current damping magnetic force spring also includes an annular third halbach permanent magnet array 5 and is arranged on the first halbach permanent magnet array 2 and the third halbach permanent magnet A second annular eddy current damper 4b between the arrays 5 .

[0030]The first halbach permanent magn...

Embodiment 2

[0044] Such as Figure 4 As shown, the eddy current damping magnetic spring based on multiple halbach permanent magnet arrays in the present invention can also be set as a disc spring formed by stacking each component. In the second embodiment of the present invention, the eddy current damping magnetic spring 11 based on a plurality of halbach permanent magnet arrays includes an annular first halbach permanent magnet array 12, a second halbach permanent magnet array 13, and a third halbach permanent magnet array 16 And the first eddy current damper 14a, the second eddy current damper 14b, wherein the first halbach permanent magnet array 12, the second halbach permanent magnet array 13 and the third halbach permanent magnet array 16 are coaxially arranged axially side by side, the first A halbach permanent magnet array 12 is arranged between the second halbach permanent magnet array 13 and the third halbach permanent magnet array 16 . The first eddy current damping element 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com