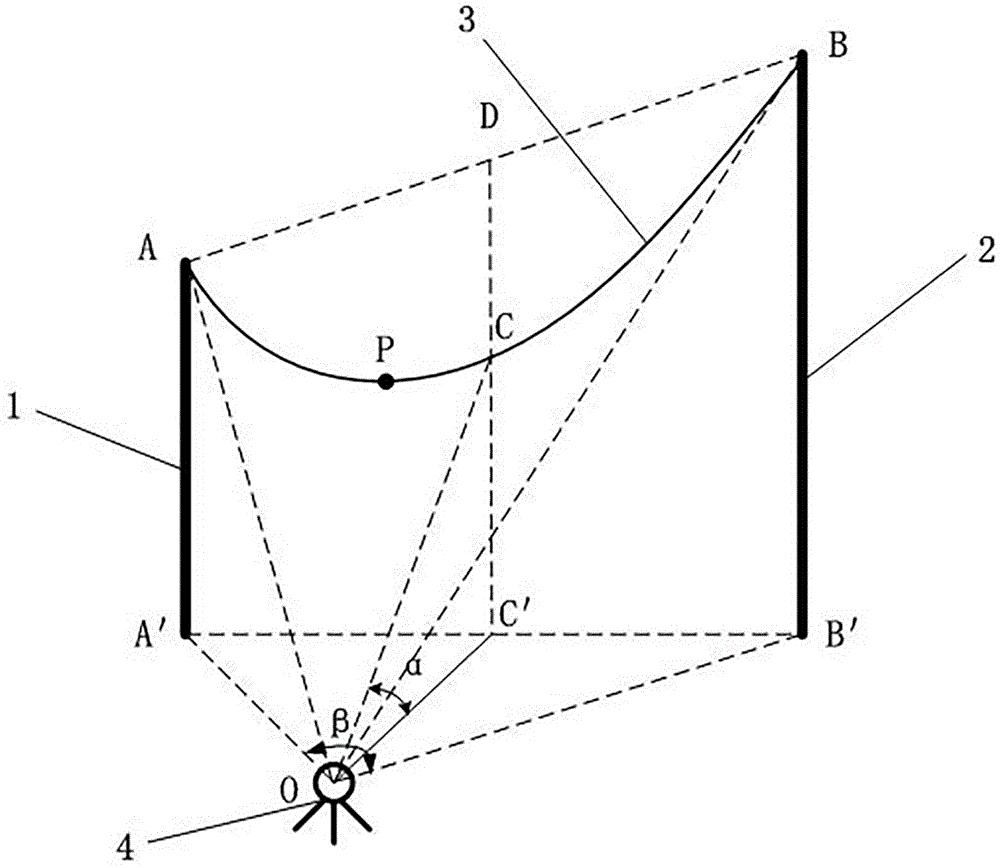

Pole-side conductor sag observation method based on total station instrument

A wire sag, total station technology, applied in the direction of instruments, measuring devices, line-of-sight measurement, etc., can solve the problems of geographical limitation and complicated calculation, and achieve the effects of accurate results, simple operation and convenient calculation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

[0031] The total station type electronic speed measuring instrument is referred to as the total station instrument. It is a kind of horizontal angle, vertical angle measurement, slant distance, horizontal distance, height difference measurement and data processing. It is composed of mechanical, optical and electronic components. of measuring instruments. Because it only needs to be installed once, the instrument can complete all the measurement work on the station, so it is called "total station". At present, most total stations have the function of prism-free observation, which is not limited by the observation location, and the operation is simple. Accurate results and increased...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com