Method for operating a driver assistance system of a motor vehicle and corresponding driver assistance system

A technology for driver assistance and motor vehicles, which is applied in the field of driver assistance systems and can solve problems such as reducing the coefficient of friction between the wheels and the ground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

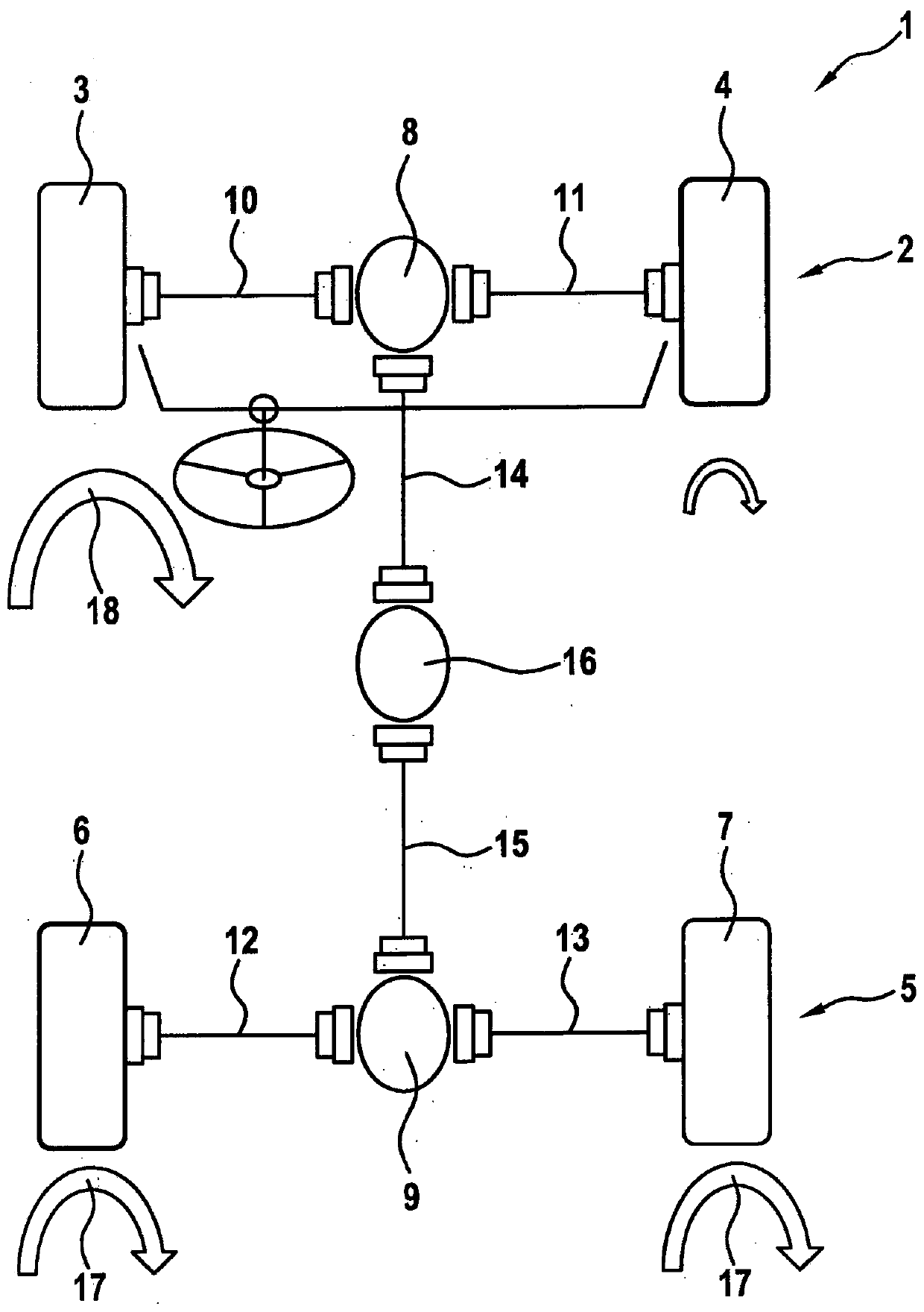

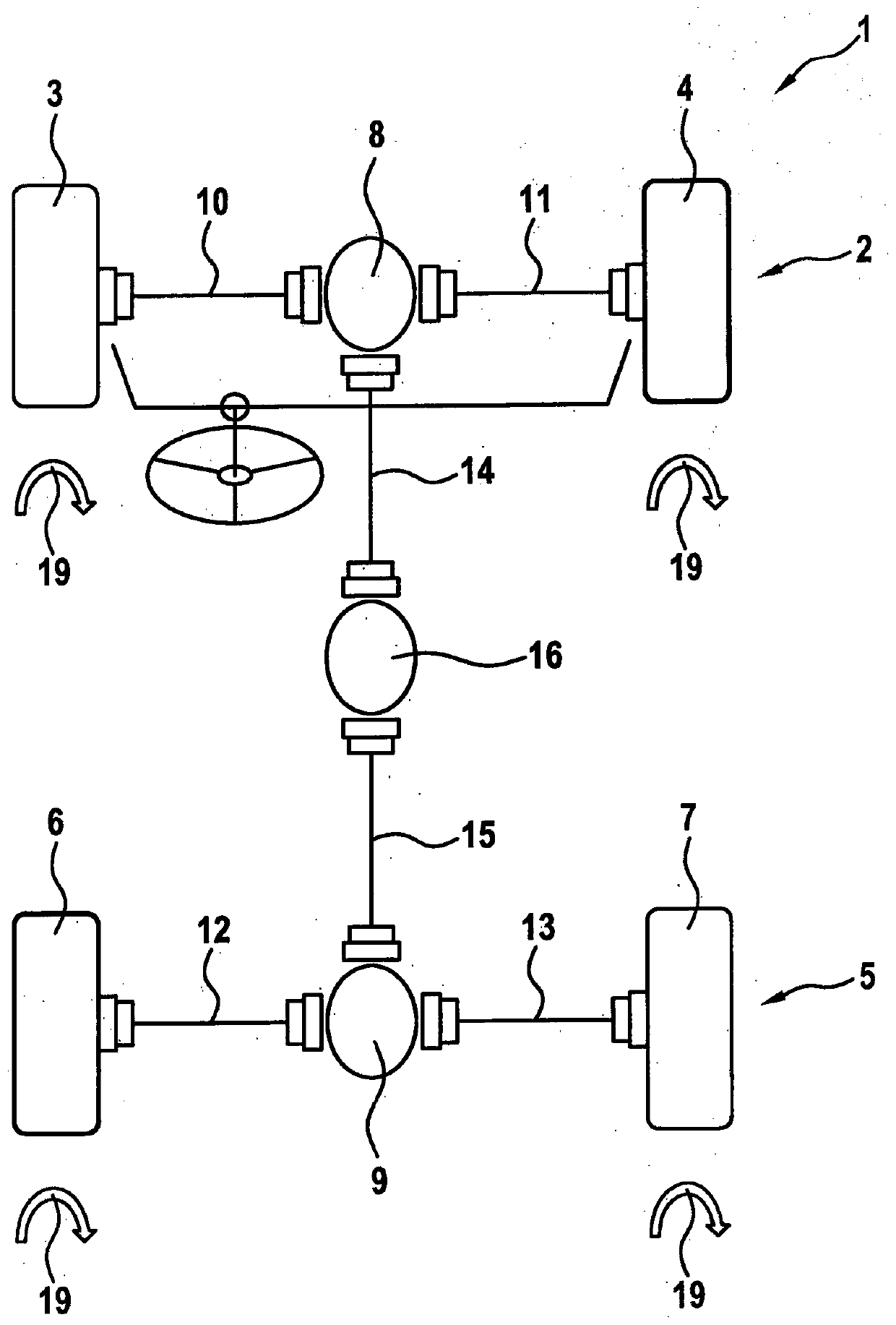

[0032] figure 1 A schematic diagram of a motor vehicle 1 is shown. The motor vehicle has a first axle 2 , for example a front axle, which has wheels 3 and 4 . Furthermore, motor vehicle 1 has a second axle 5 , for example a rear axle, which has wheels 6 and 7 . Wheels 3 and 4 of first axle 2 are operatively connected to one another via an axle differential 8 . Similarly, the wheels 6 and 7 of the second axle 5 are operatively connected to each other via an axle differential 9 . For example, the axle differential 8 has output shafts 10 and 11 , and the axle differential 9 has output shafts 12 and 13 . The wheels 3 are connected, preferably rigidly and / or permanently connected to the output shaft 10, the wheels 4 are connected, preferably rigidly and / or permanently connected to the output shaft 1, and the wheels 6 are connected, preferably rigidly and / or permanently is connected to the output shaft 12 and the wheel 7 is connected, preferably rigidly and / or permanently connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com