A processing device for multi-line large-pitch helical internal thread of parts

A technology of processing device and large pitch, applied in tangent device, tangent feed device, positioning device, etc., can solve the problems of instable machining accuracy of parts, low machining efficiency and machining accuracy, and large transmission error of guide rails and screw rods. Achieve the effect of low skill level and experience requirements, ensuring machining accuracy and efficiency, and avoiding pitch errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

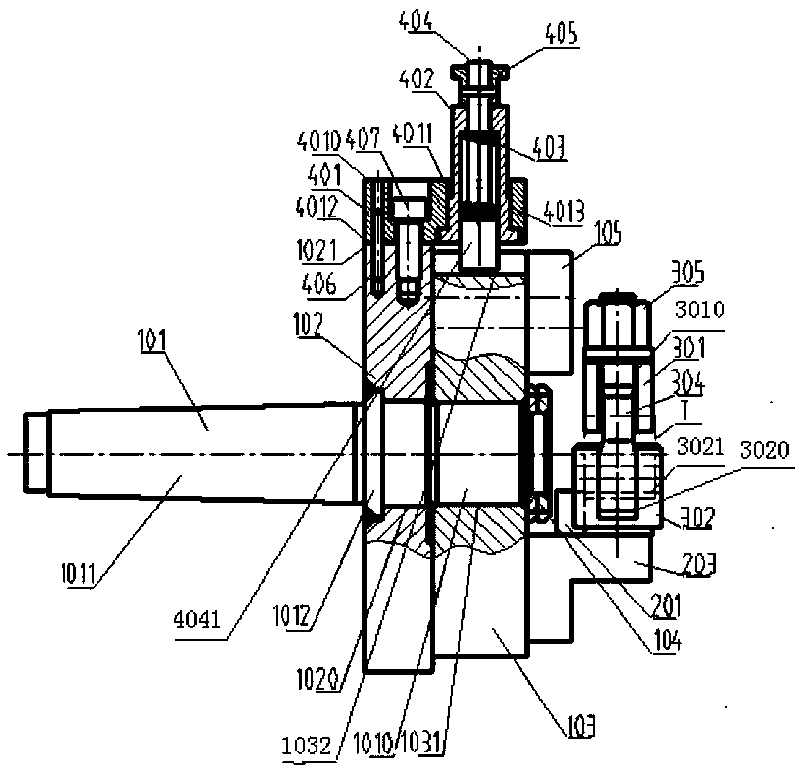

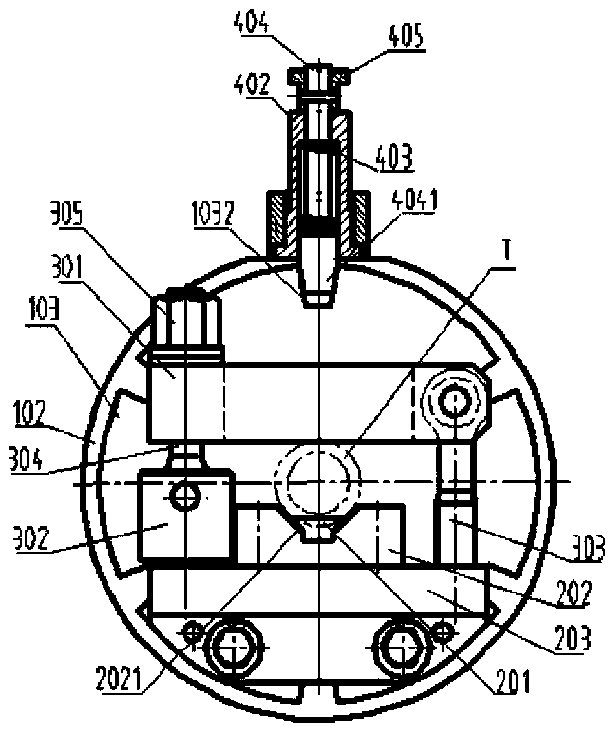

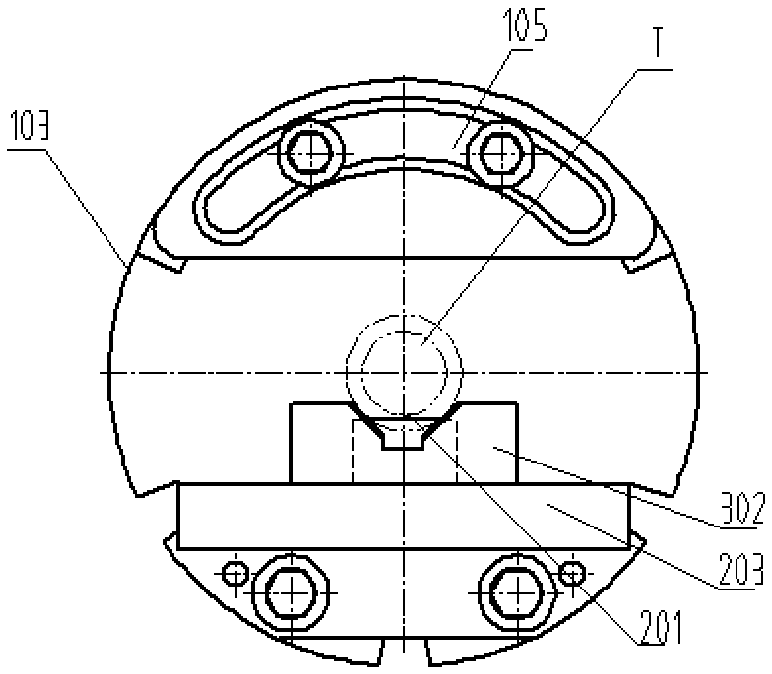

[0026] see Figure 1 to Figure 8 , The processing device of the multi-thread large-pitch spiral internal thread of the parts of the present invention includes an indexing mechanism, a positioning mechanism, a pressing mechanism and a locking mechanism. Depend on Figure 1 to Figure 8It can be seen that the indexing mechanism includes a connector 101, a disk 102, an index plate 103, a lock nut 104 and a counterweight 105, and the connector 101 includes a mandrel 1010 with an external thread on the right end and connected to the mandrel. The shaft 1010 is integrated and extends to the left from the mandrel 1010, and its outer contour shape and size are suitable for the assembly hole on the ordinary lathe spindle. The isolating part 1012 at the junction of the disk 102 is assembled on the mandrel 1010, and its left end face is attached to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com