Washing machine variable frequency motor brake control method and washing machine

A brake control and variable frequency motor technology, which is applied to the control device of washing machines, other washing machines, washing devices, etc., can solve the problems of long braking speed of the motor, the inability to decelerate the motor, and potential safety hazards, and achieve the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

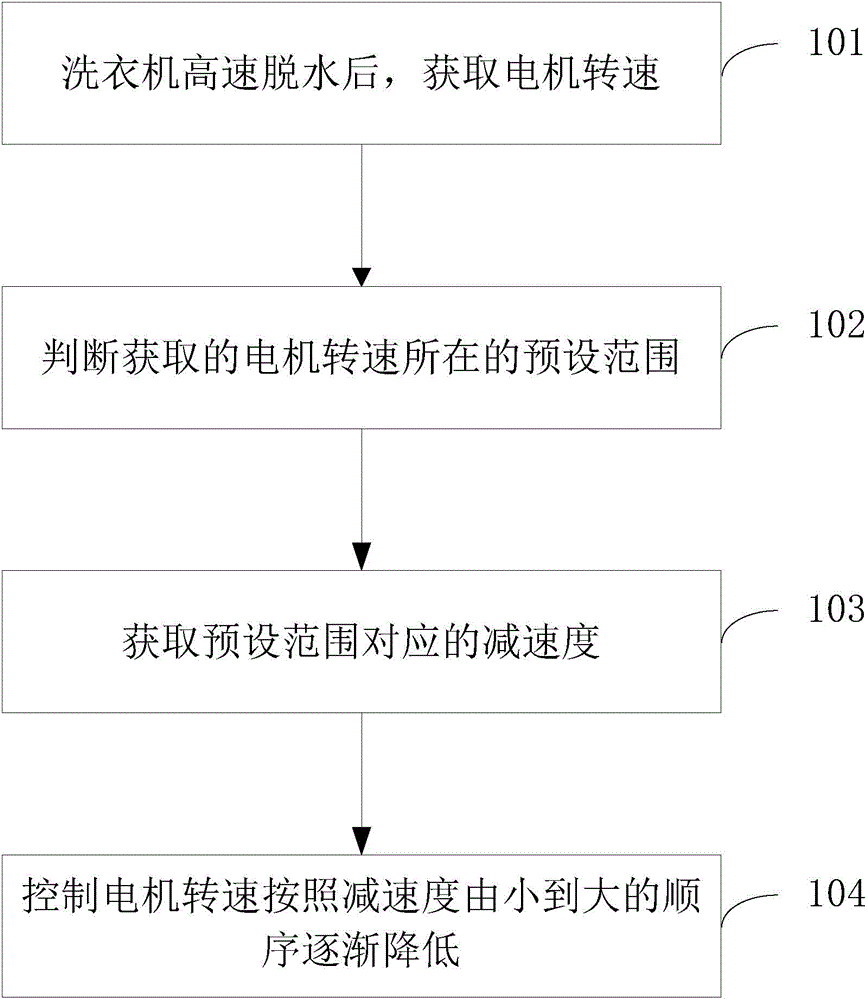

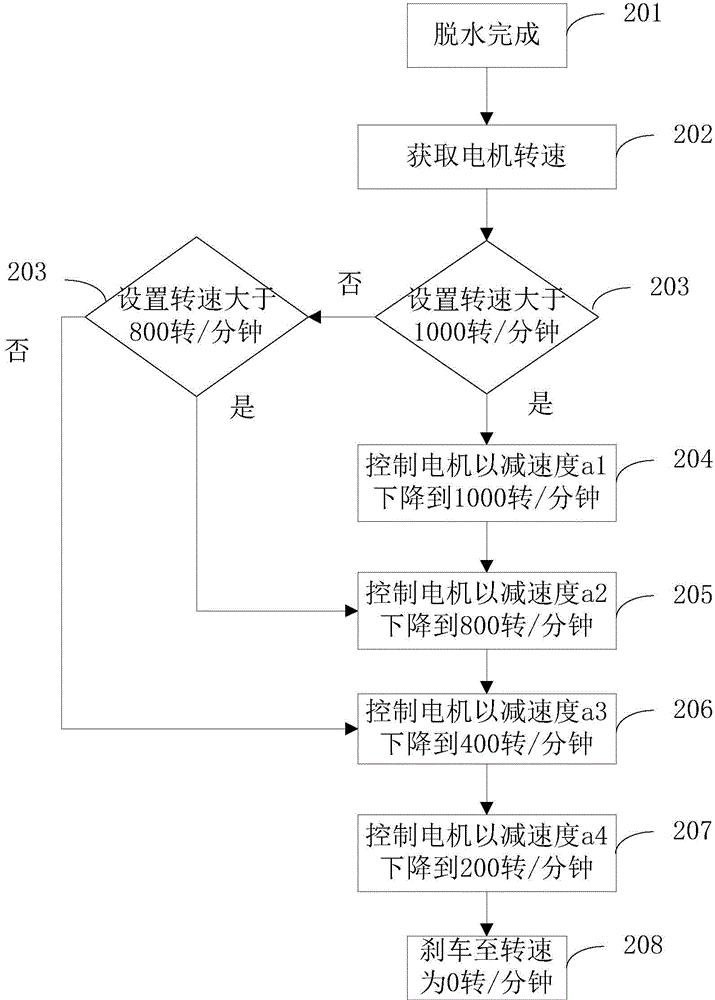

[0087] In this embodiment, after the high-speed dehydration of the washing machine, the preset range of the motor speed is first judged, and then the decelerations corresponding to the preset ranges are obtained, and the current motor speed is detected in real time. When the critical value of the rotational speed is reached, switch to the next deceleration and continue to run until the motor rotational speed drops to 0 r / min. The relationship is shown in Table 2. Such as figure 2 As shown, the braking process performed by the washing machine includes:

[0088] Step 201: The dehydration of the washing machine is completed.

[0089] Step 202: Obtain the motor speed.

[0090] Preferably, the motor speed can be obtained by detecting the current motor speed of the washing machine;

[0091] Preferably, the motor speed can be obtained by reading the highest motor speed set by the washing machine program.

[0092] Step 203: Determine the set speed, if it is above 1000 rpm, execu...

Embodiment 2

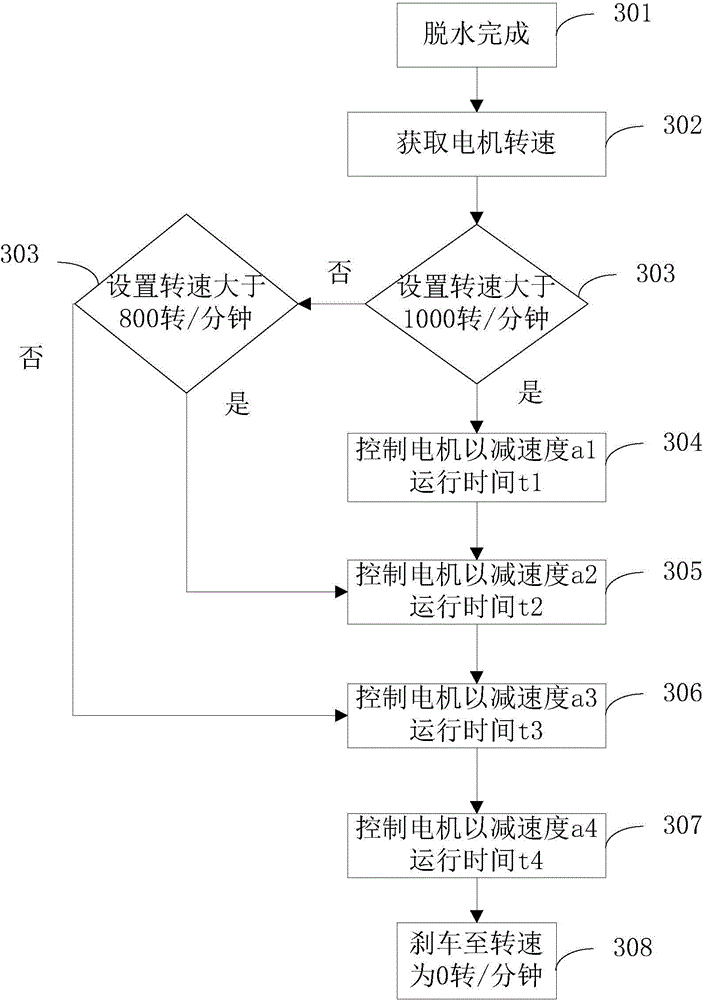

[0101] In this embodiment, after the high-speed dehydration of the washing machine, first determine the preset range of the motor speed, and then obtain each deceleration corresponding to the preset range, and the preset time corresponding to each deceleration, and the motor speed runs according to the current deceleration After the preset time corresponding to the current deceleration, switch to the next deceleration and continue to run until the motor speed is 0 rpm, wherein, the corresponding relationship between the preset range and the deceleration is shown in Table 1. The corresponding relationship of time is shown in Table 3. Such as image 3 As shown, the braking process performed by the washing machine includes:

[0102] Step 301: The dehydration of the washing machine is completed.

[0103] Step 302: Obtain the motor speed.

[0104] Preferably, the motor speed can be obtained by detecting the current motor speed of the washing machine;

[0105] Preferably, the mo...

Embodiment 3

[0115]In this embodiment, after the high-speed dehydration of the washing machine, the deceleration and the preset time corresponding to the deceleration stored in the storage module are directly acquired, and the motor speed is switched to the next one after running at the current deceleration for the preset time corresponding to the current deceleration. The deceleration continues to run until the motor speed is 0 r / min, and the corresponding relationship between the deceleration and the preset time is shown in Table 3. Such as Figure 4 As shown, the braking process performed by the washing machine includes:

[0116] Step 401: The dehydration of the washing machine is completed.

[0117] Step 402: Control the motor speed to run for a time t1 at a deceleration a1.

[0118] Step 403: Control the motor speed to run for a time t2 at a deceleration a2.

[0119] Step 404: Control the motor speed to run for a time t3 at a deceleration a3.

[0120] Step 405: Control the rotatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com