Polarization imaging principle-based polarization maintaining fiber axis alignment device and axis alignment method

A polarization-maintaining optical fiber and imaging principle technology, applied in polarized optical fiber, cladding optical fiber, installation, etc., can solve the problems of high environmental requirements and slow axis fixing speed, and achieve the effect of fast axis fixing speed and guaranteed coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in more detail below with examples in conjunction with the accompanying drawings.

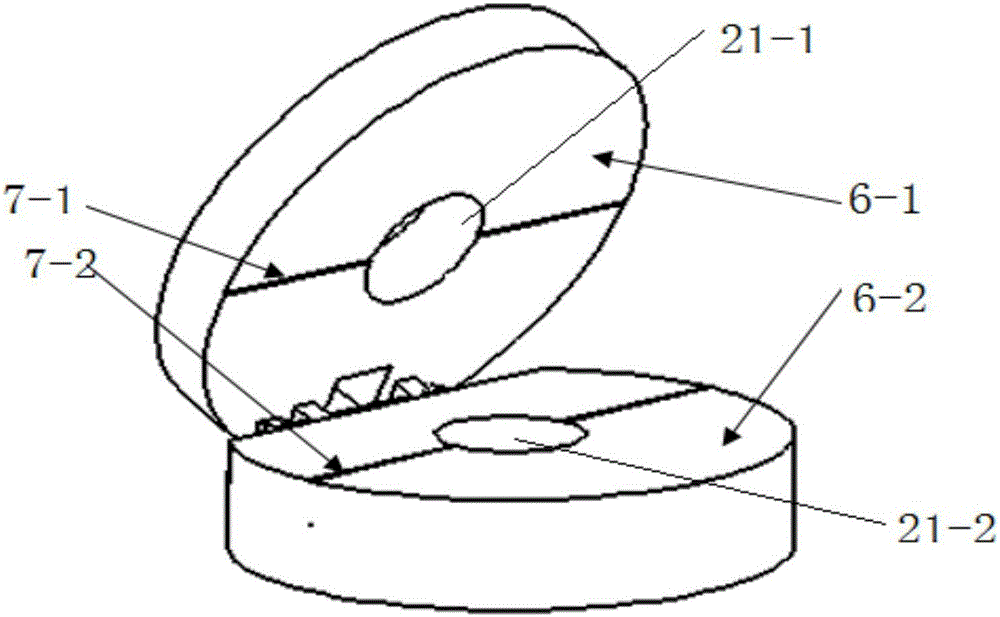

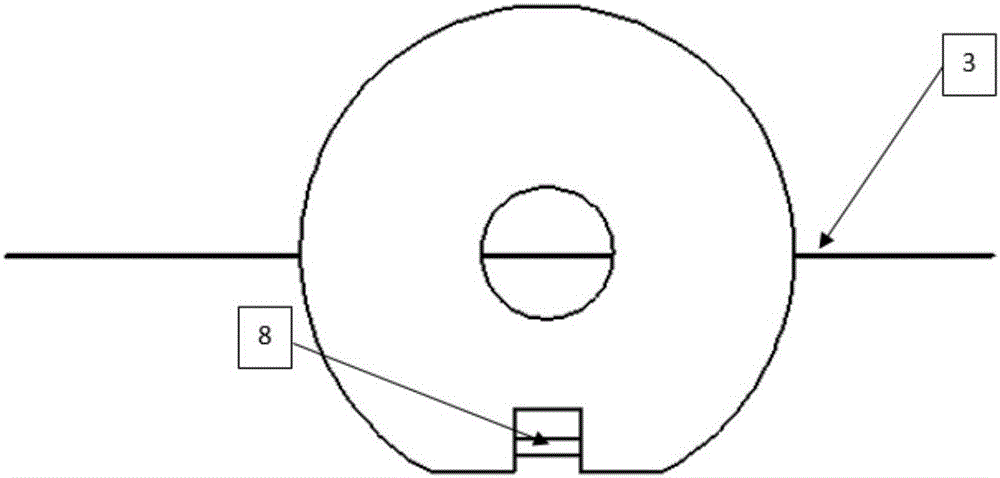

[0023] combine figure 1 with figure 2 , the polarization-maintaining optical fiber axis fixing device based on the polarization imaging principle of the present invention comprises an upper optical fiber limiting plate 6-1 and a lower optical fiber limiting plate 6-2, one side of the upper and lower optical fiber limiting plates is connected by a cylindrical shaft 8, and the upper and lower optical fibers There are circular holes 21-1 and 21-2 on the limiting plate, and semicircular grooves 7-1 and 7-2 passing through the circular holes are opened on the upper and lower optical fiber limiting plates. The diameters of the semicircular slots are equal. The semicircular grooves on the upper and lower optical fiber limiting plates have been polished.

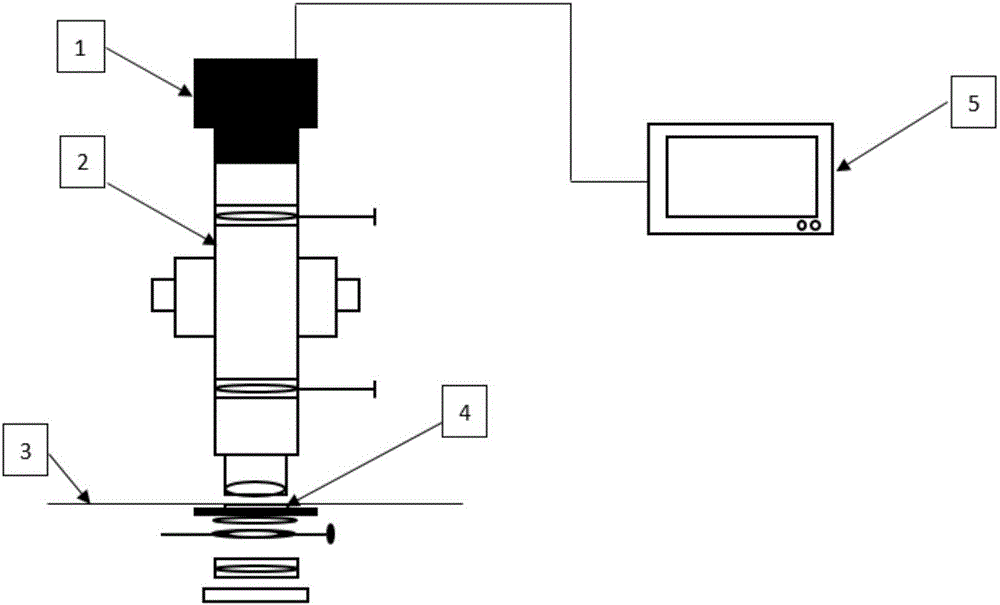

[0024] combine image 3 with Figure 4 , the axis-fixing system used in the polarization-mainta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com